Clamping technology:

für maximale leistung

Precision & innovation

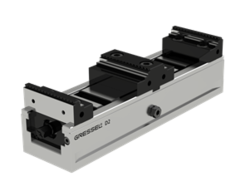

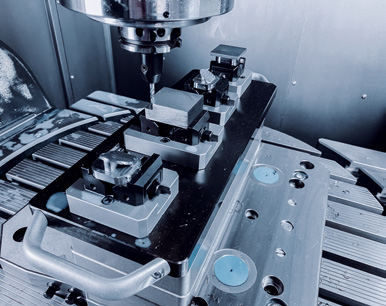

At GRESSEL, we set the standard in clamping technology with precision and innovation. Our clamping systems are specially developed for the requirements of modern production environments and offer efficiency and reliability.

Our clamping technology solutions offer an answer to the challenges of metalworking and CNC manufacturing. Whether standard products or customer-specific clamping solutions, GRESSEL clamping technology optimizes machine running times. Our products are designed to reduce workpiece costs and increase production capacity at the same time.

Why GRESSEL clamping technology?

Get the maximum

out of your production!

With GRESSEL clamping technology you increase your productivity. Experience our variety of products. Experience for 100 years from workshop equipment to milling machine automation.

Why GRESSEL clamping technology?

Get the maximum

out of your production!

With GRESSEL clamping technology you increase your productivity. Experience our variety of products. Experience for 100 years from workshop equipment to milling machine automation.

Problems? Our solutions.

You have no desire

more for ...

... too less machines spindle running times?

z. e.g. no multiple clamping, no workpiece automation,…

We show you how you can increase your machine spindle running times with our clamping technology

... too many unproductive hours?

e.g. conversion times too long, handling awkward,… With us you will find products with easy handling, quick jaw change, easy conversion with the zero point clamping system gredoc

... too inflexible

Clamping technology?

E.g. no 6 sides manufacturing, no jaw variety,…

Get to know our product diversity, 100 years of GRESSEL from workshop equipment to automation

Make your appointment

In 3 steps to a

better productivity

Personal individual advice

Experienced GRESSEL technicians take care of you personally and with great commitment

Clamping device test at your production site

Buying directly is too risky for you? With us you can test all clamping devices in advance free of charge

Problems? Our solutions.

You have no desire

more for ...

... too less machines spindle running times?

z. e.g. no multiple clamping, no workpiece automation,…

We show you how you can increase your machine spindle running times with our clamping technology

... too many unproductive hours?

e.g. conversion times too long, handling awkward,… With us you will find products with easy handling, quick jaw change, easy conversion with the zero point clamping system gredoc

... too inflexible

Clamping technology?

E.g. no 6 sides manufacturing, no jaw variety,…

Get to know our product diversity, 100 years of GRESSEL from workshop equipment to automation

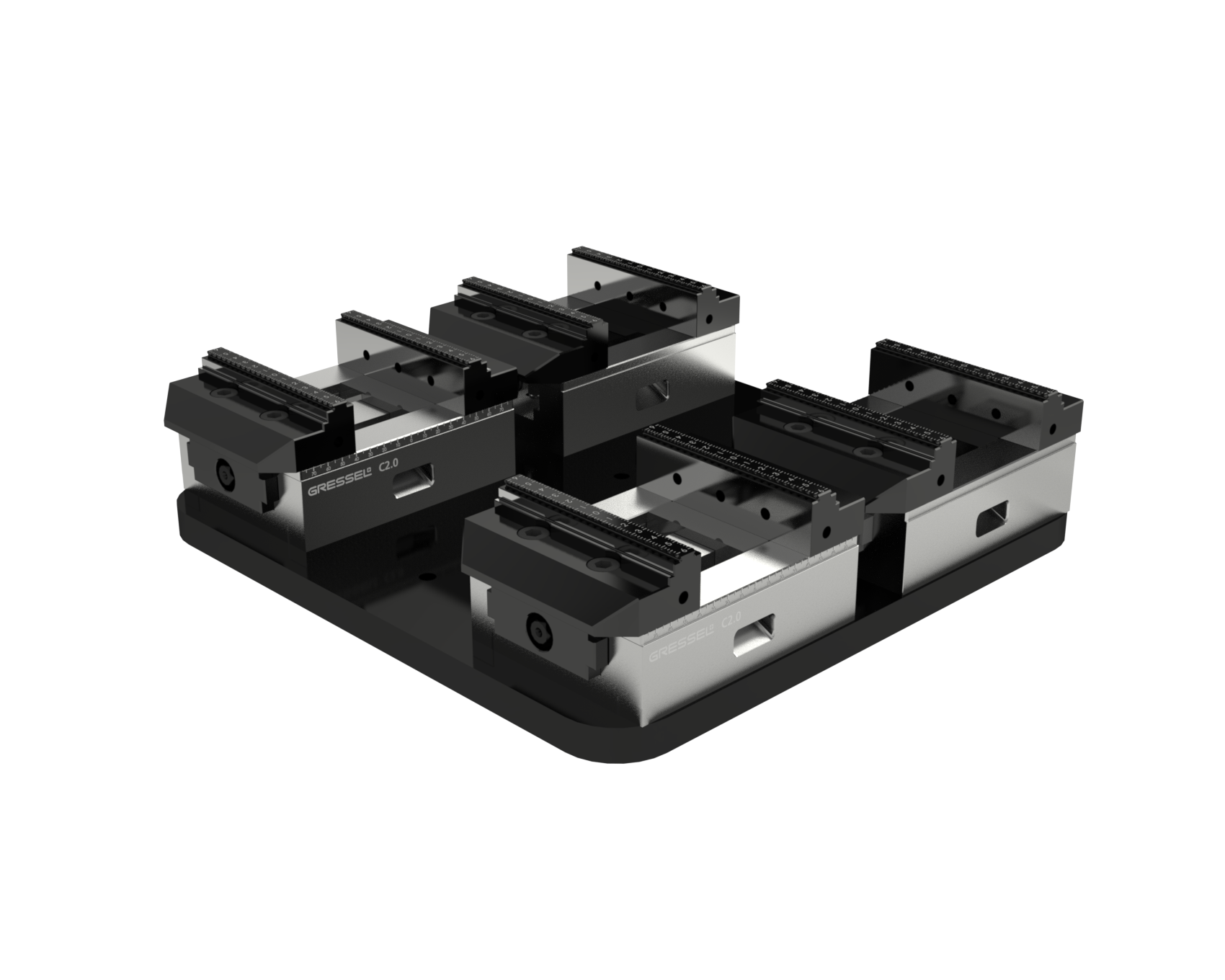

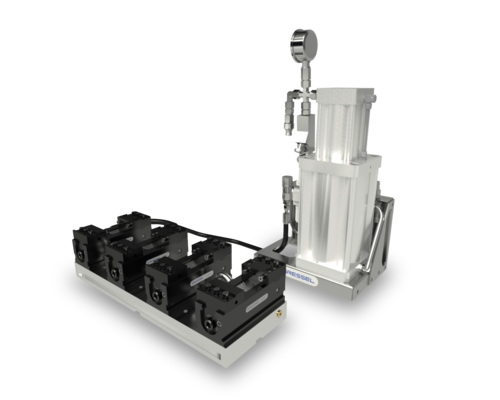

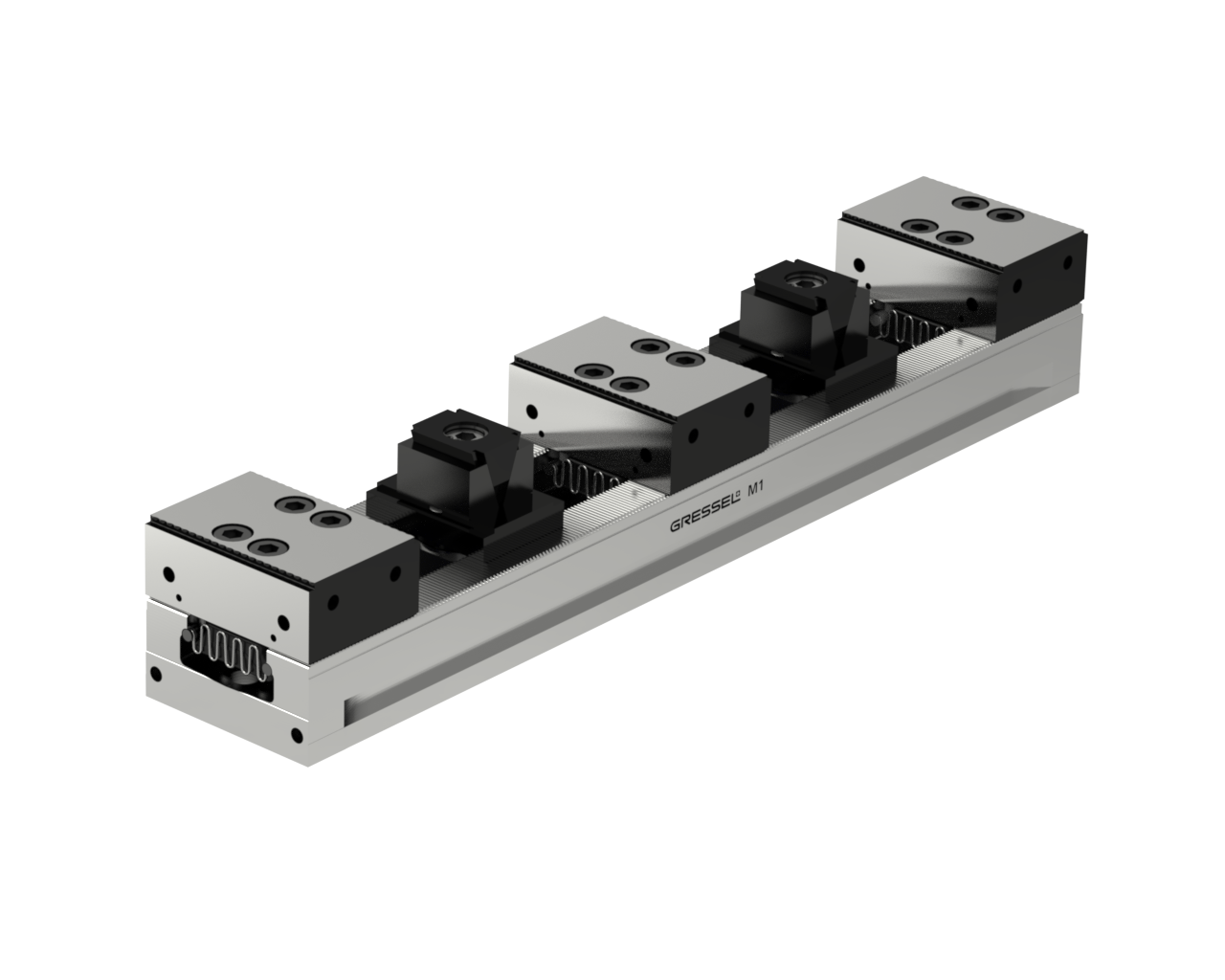

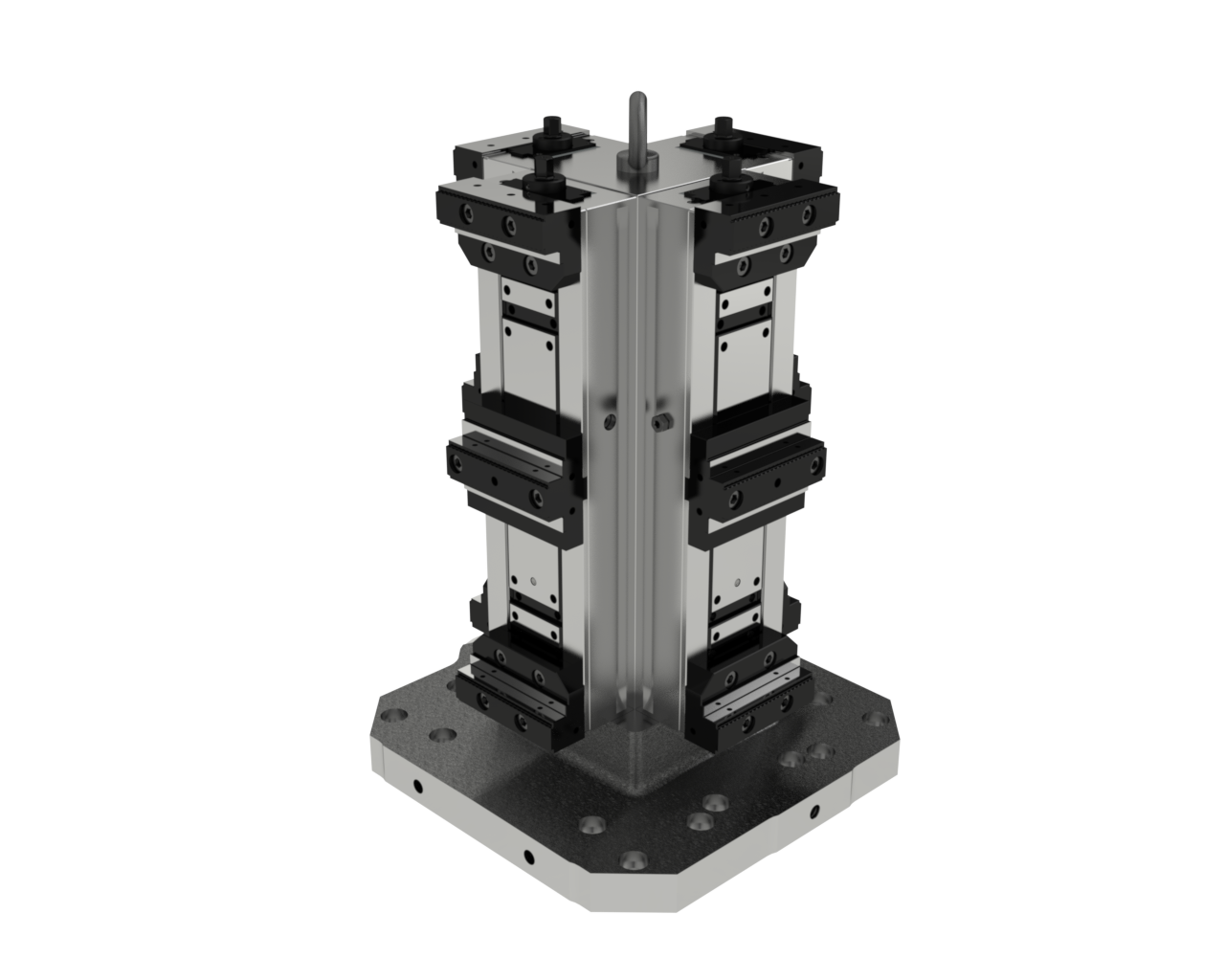

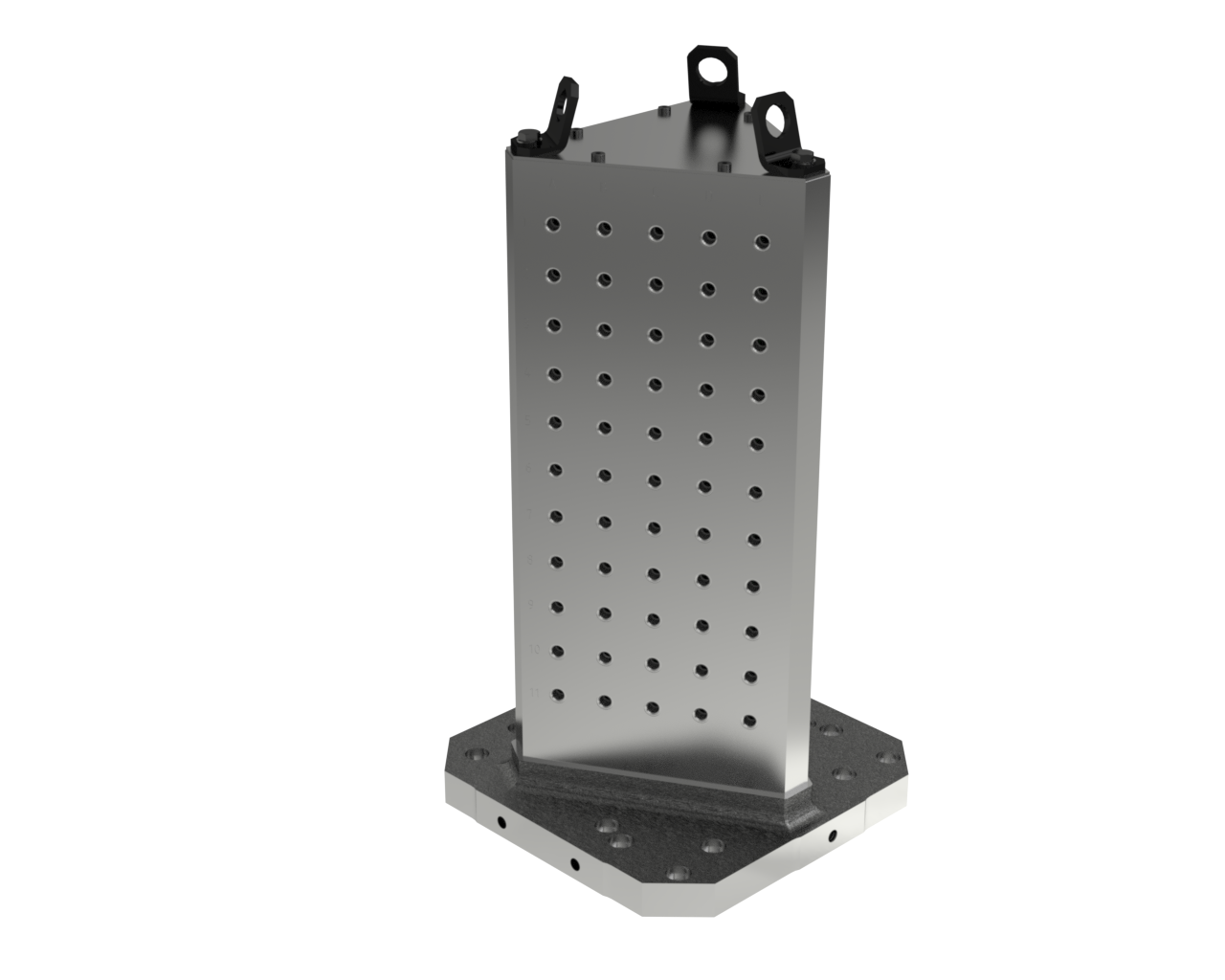

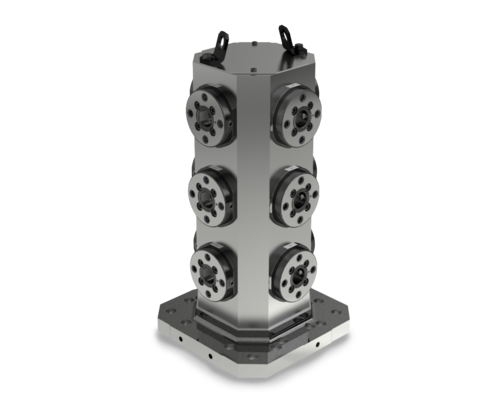

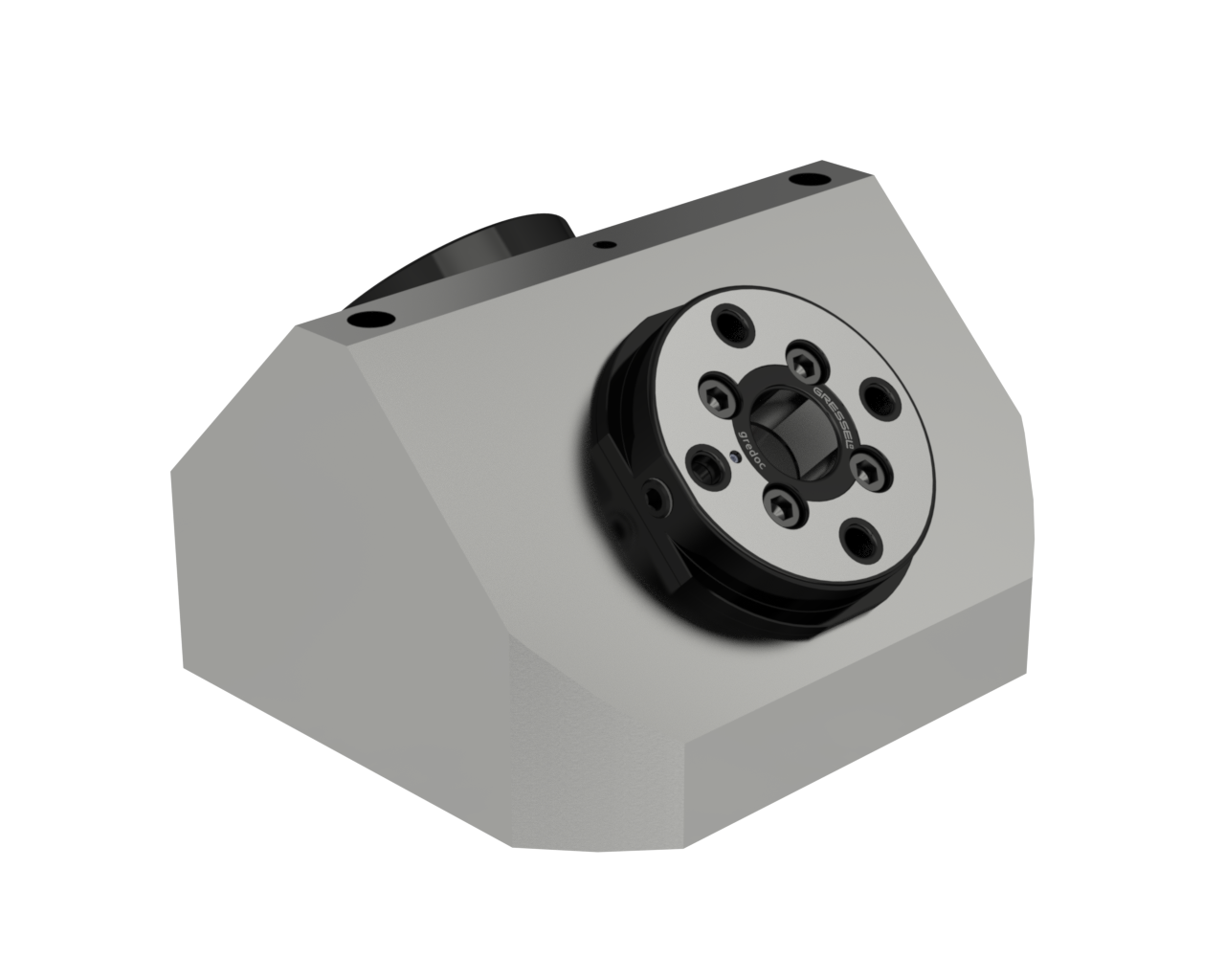

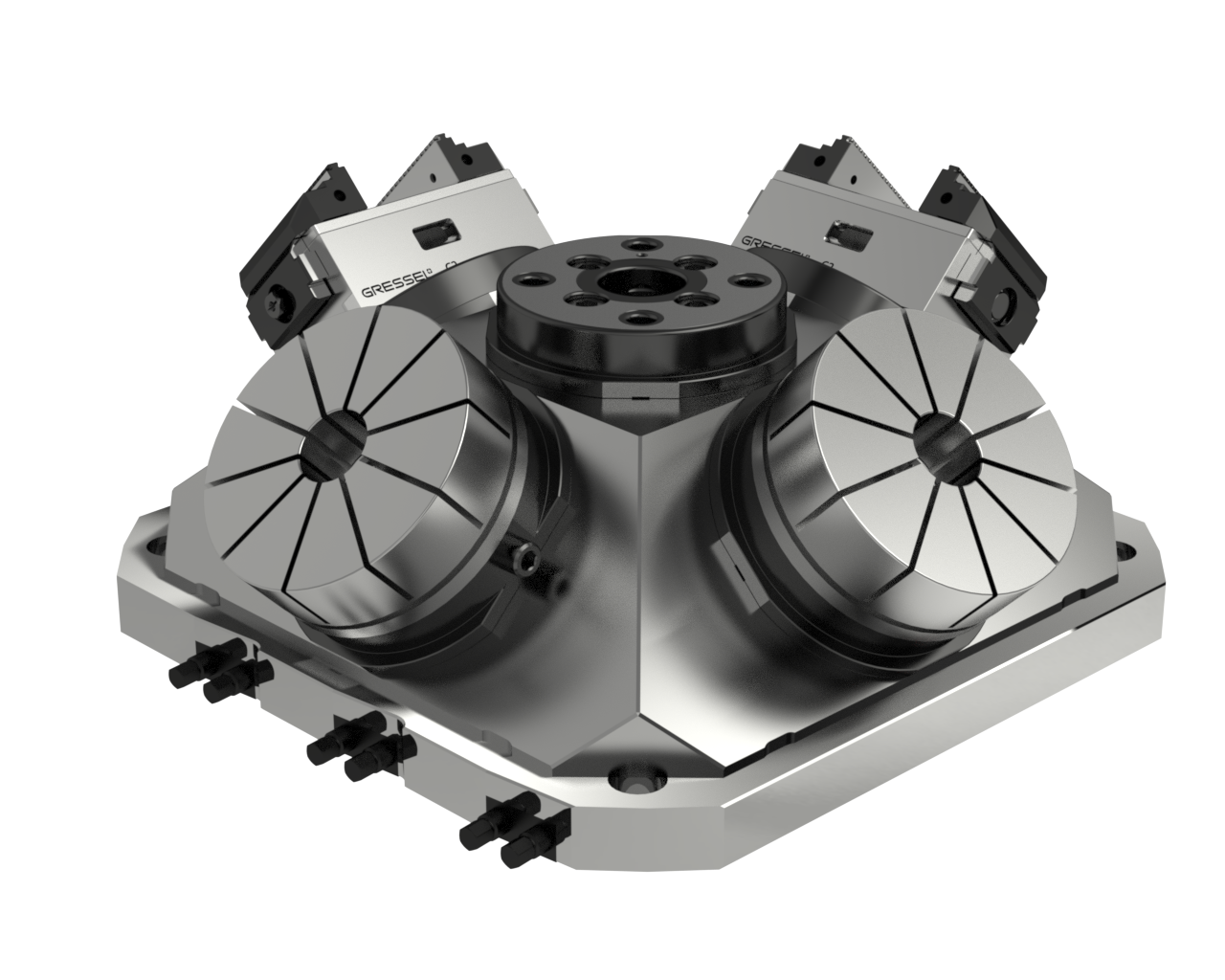

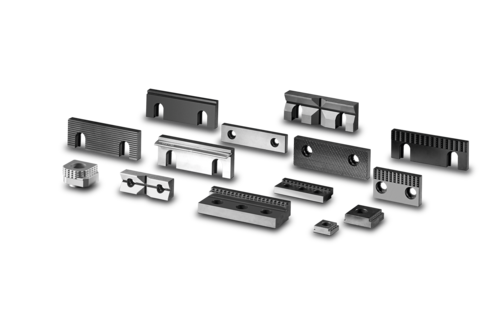

Our range. Our pride and joy.

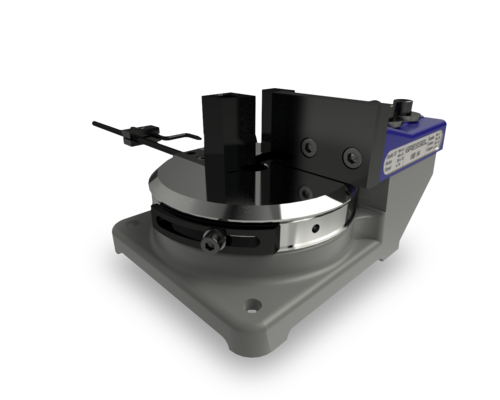

With us you will find the right solution for 3-, 4- and 5-axis machines

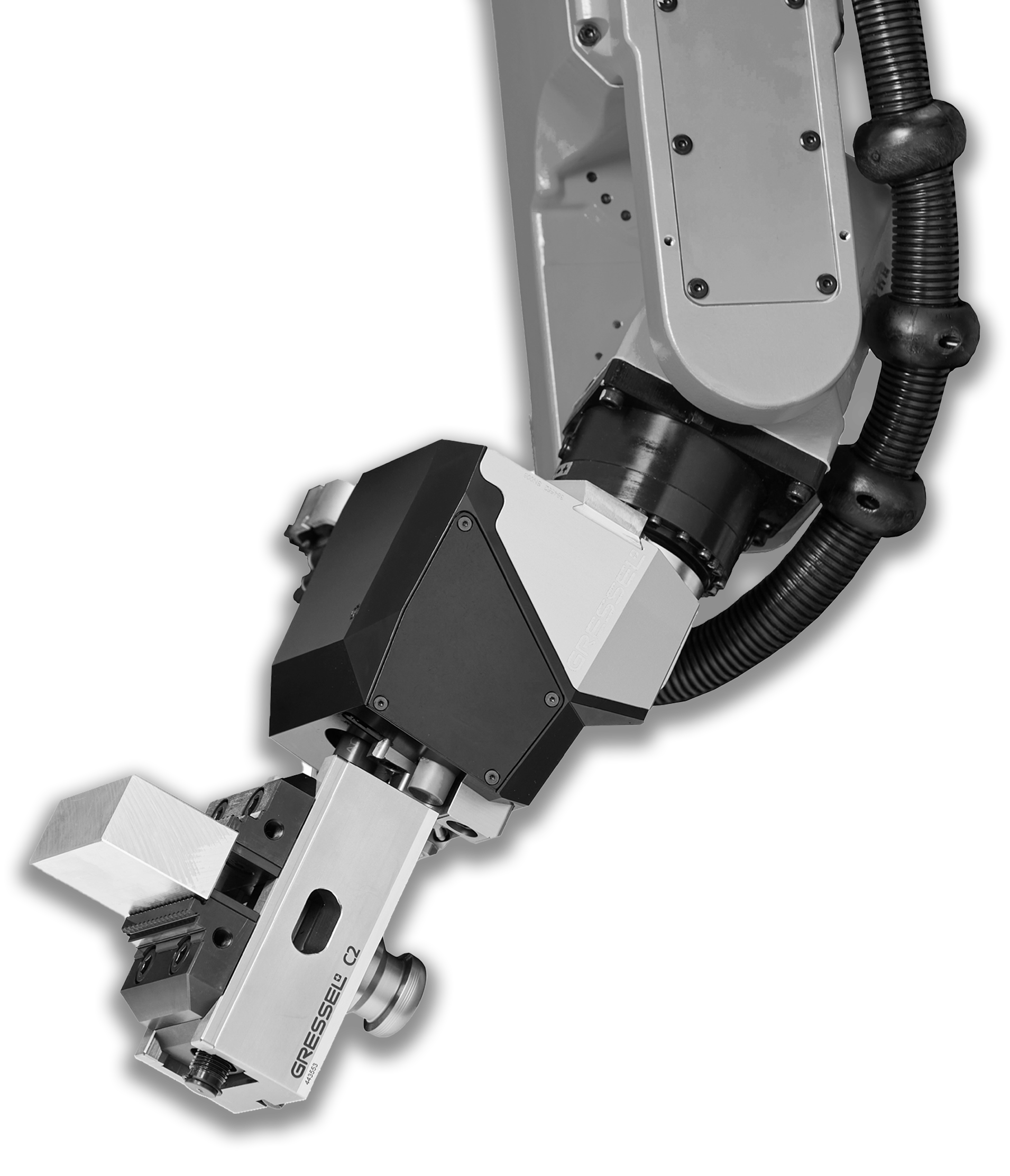

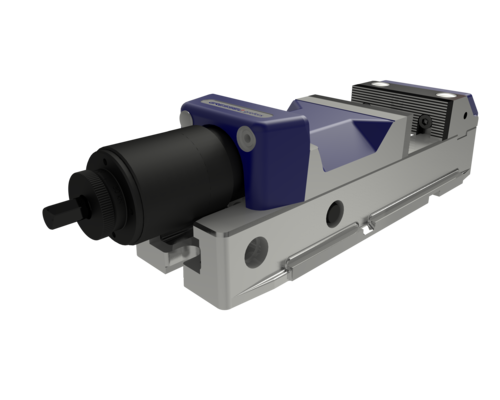

The proven GRESSEL clamping technology combined with the highest level of CNC automation.

For use in semi-automatic and fully automatic operation with robot loading or just simple and quick operation

Highly efficient all-rounder for machining unmachined and finished parts

High accuracy and high efficiency – multiple clamping on workholding towers and in pallets Automation

Ssmall and large workpieces can be easily clamped on a 3-, 4-, or 5-axis machine

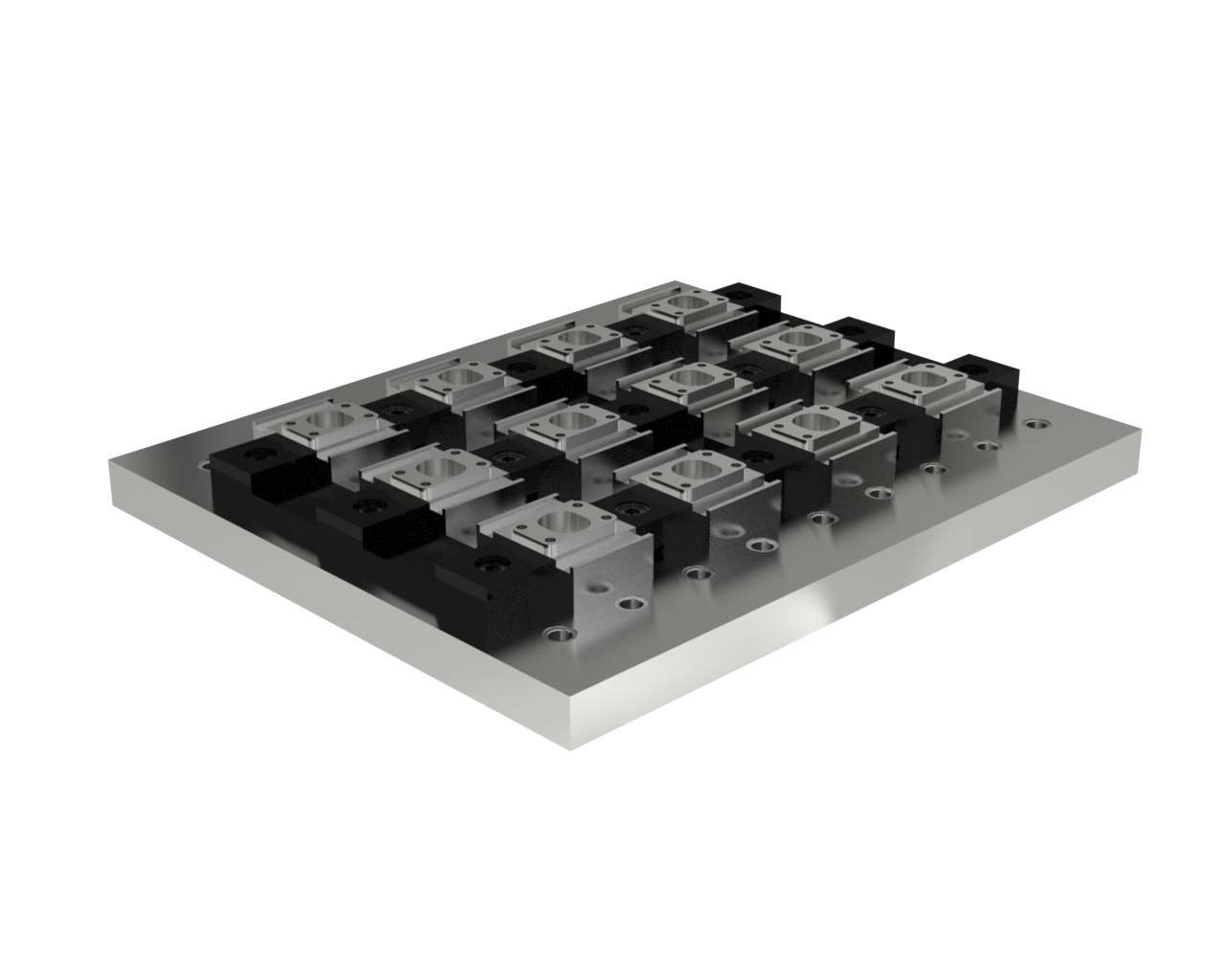

Mechanical zero point clamping system – low, precise and cost-effective!

Mechanical zero point clamping system gredoc NRS – The all-round plates for every machine table!

for 4- and 5-axis machines and pallet automation

Manufacturing process optimization for maximum productivity

Manufacturing process optimization for maximum productivity

Manufacturing process optimization for maximum productivity

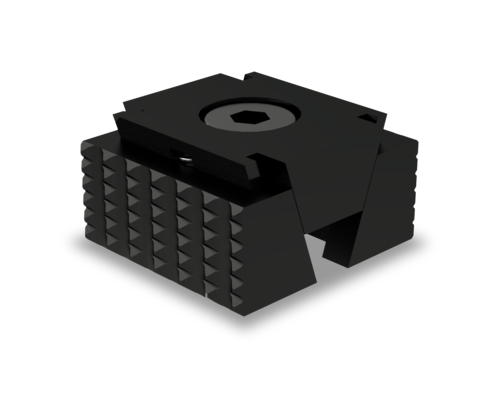

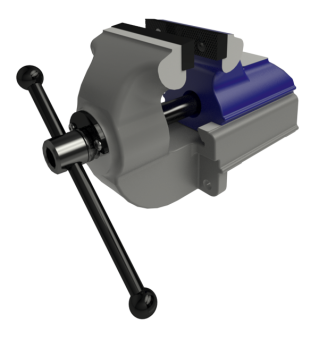

Proven, robust and wear-free!

Made of durable ductile or special cast iron, with hewn, smooth or prism jaws.

Proven, robust and wear-free!

Made of durable ductile or special cast iron, with hewn, smooth or prism jaws.

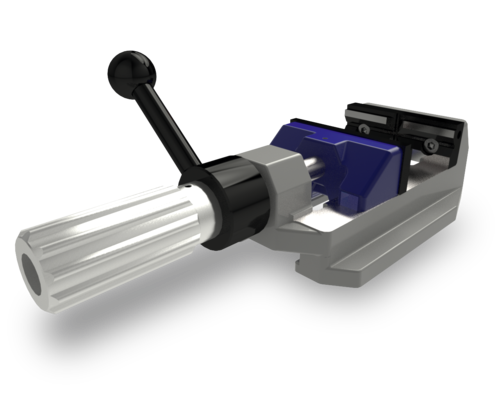

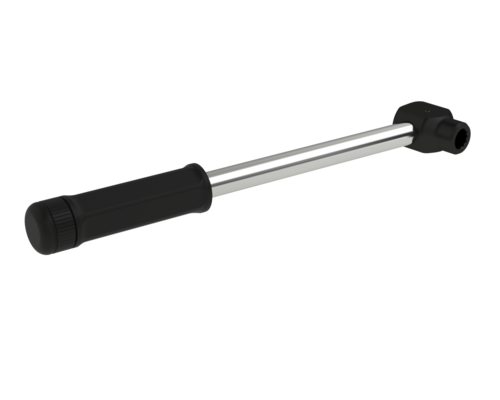

Full working safety due to guide rail. Freely positionable workpiece with secure clamping, can be operated with one hand.

Bending without effort

Easy-to-operate, high-performance bending machine for accurate bending of round, flat, upright material and other profiles up to 180°.

With us you will find the right solution for 3-, 4-, 5-axis machines

The proven GRESSEL clamping technology combined with the highest level of CNC automation

For use in semi-automatic and fully automatic operation with robot loading or just simple and quick operation

Make your appointment

In 3 steps to a

better productivity

Personal individual advice

Experienced GRESSEL technicians take care of you personally and with great commitment

Clamping device test at your production site

Buying directly is too risky for you? With us you can test all clamping devices in advance free of charge

Our GRESSEL Blog

latest

Articles

In our GRESSEL Blog we present you weekly interesting articles about workpiece clamping technology, GRESSEL products in practice, milling machine automation and exciting company information.

97% capacity utilization achieved through automation

In an interview with Maschinenbau Grissemann GmbH. With our workpiece automation, we were able to increase the efficiency and flexibility of Maschinenbau Grissemann GmbH.

EMO 2023 Review

Visitors to the GRESSEL AG stand in hall 5, booth no. A23, were able to experience the latest developments and innovative products at first hand. Here are some of the highlights we presented during EMO 2023

C3 Small part centering vise

Small part centric vise C3 – in mechanical design with jaws quick change, high clamping force and stainless base body.

YOU CAN FIND US HERE

In the middle of aadorf

Let's work on technical revolutions.

From a mechanical workshop to a specialist in efficient workpiece clamping technology – the Swiss company GRESSEL AG has been involved in metalworking for almost 100 years. We ensure continuity in our relationship with customers, suppliers and employees as an independent, autonomous family business.

YOU CAN FIND US HERE

In the middle of aadorf

Let's work on technical revolutions.

From a mechanical workshop to a specialist in efficient workpiece clamping technology – the Swiss company GRESSEL AG has been involved in metalworking for almost 100 years. We ensure continuity in our relationship with customers, suppliers and employees as an independent, autonomous family business.

Understanding customer needs

Our primary goal

Your satisfaction

Let our workholding specialists advise you competentlyand indetail. Make an appointment to visit us at your site to see a live demonstration of our GRESSEL clamping systems or to test our clamping devices on your machines.

Matthias Zünd

Head of sales GRESSEL & SCHUNK

Switzerland

Mobil: +41 79 760 67 32

matthias.zuend@gressel.ch

Sokha Hem

Distribution engineer

GER South, AT, CZ, SK, PL, CR, GB

Mobil: +43 664 105 2439

sokha.hem@gressel.ch

Understanding customer needs

Our primary goal

Your satisfaction

Let our workholding specialists advise you competentlyand indetail. Make an appointment to visit us at your site to see a live demonstration of our GRESSEL clamping systems or to test our clamping devices on your machines.

Sokha Hem

Distribution engineer

GER South, AT, CZ, SK, PL, CR, GB

Mobil: +43 664 105 2439

sokha.hem@gressel.ch

Matthias Zünd

Head of sales GRESSEL & SCHUNK

Switzerland

Mobil: +41 79 760 67 32

matthias.zuend@gressel.ch

PURE clamping technology

Our catalog

sent for free.

CLAMPING TECHNOLOGY AT ITS BEST