INCREASE IN MACHINE RUNNING TIME DUE TO CENTRIC CLAMPING

The company SIBA mainly produces quantities between 20 – 3000 pieces per order. The customer’s goal was to increase the machine runtimes on his 3-axis machine type Kunzmann BA 1500.

ATTENTION – OUR NEW FLYER SC5X IS HERE

Are you looking for a 5-axis clamp with which you can machine all 6 sides of the workpiece?

You want fast handling and best accessibility?

You may want to automate this 5-axis clamp later?

Beat as a team in the same beat!

Last Thursday we had our staff event, finally we could exchange with all colleagues again.

Our machinery

We are proud of our modern and automated machinery!

We wish you happy holidays!

The year is slowly coming to an end…

Please note our company vacation from Friday, December 24, 2021 to Sunday, January 2, 2022 inclusive.

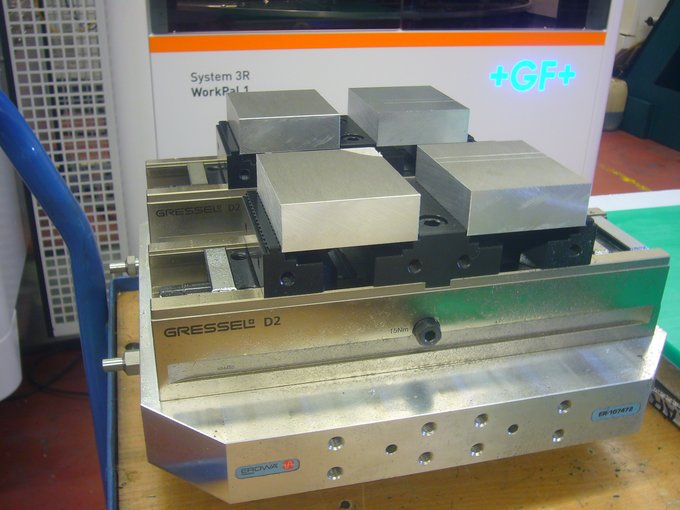

Pallet automation

You have decided in favor of a pallet automation?

We have the ideal clamping technology for this with our GRESSEL clamping technology modular system – C2 centric clamps, S2 single clamps and D2 double clamps.

Clamping of “shapeless” parts: Casting, forging, flame cutting, additive manufactured components

Vices have always been used to clamp “rectangular” components such as cuboids, strips and rails. Pendulum jaws can also be used to clamp “angled” components such as imprecise saw cuts. With the pocket technique, the negative shape of the component is milled into the usually soft jaws. Thus, it is possible to clamp almost any contours. However, a corresponding set of jaws is usually required for each component.

System solutions in workpiece clamping technology

100% vertical integration for thousands of live parts – a new production concept based on a Flexible Manufacturing Center as well as the system capability and flexible use of Gressel’s workpiece clamping technology led the machine manufacturer Illig into new dimensions of rational and economical parts production.

GRESSEL AG and SCHUNK Intec AG merge clamping technology sales in Switzerland

In order to bundle sales activities and to focus on the Swiss market, SCHUNK Intec and GRESSEL are merging the sales team for workholding technology in Switzerland.

You can also increase your profitability

In 2020, the customer purchased a new 5-axis machine type Spinner U630 in order to be able to machine the components and workpieces more efficiently and economically.