Your benefits

With our

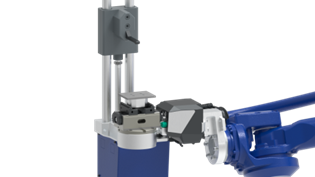

Workpiece automation R-C2

Flexiblebatch size production with high part variety

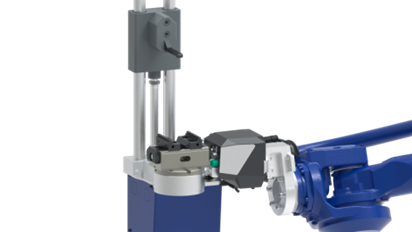

The R-C2 workpiece automation is the solution between pallet automation and robot direct loading, as the GRESSEL vise automation combines both advantages. This means much less setup effort and much more flexibility.

…R-C2 is the next logical step in milling machine automation!

ohne Rüst-/Umrüstzeit

0 – 226 mm

vollautomatisch

R-C2 80 & R-C2 125 (L-140 bis L-235 mm)

vollautomatisch

vollautomatisch

von allen Seiten

mit einer chaotischen Werkstück-Komplettfertigung

von allen 6 Werkstück Seiten

vollautomatisch

ohne Rüst-/Umrüstzeit

0 – 226 mm

vollautomatisch

R-C2 80 & R-C2 125 (L-140 bis L-235 mm)

vollautomatisch

vollautomatisch

von allen Seiten

mit einer chaotischen Werkstück-Komplettfertigung

von allen 6 Werkstück Seiten

vollautomatisch

ohne Rüst-/Umrüstzeit

0 – 226 mm

vollautomatisch

R-C2 80 & R-C2 125 (L-140 bis L-235 mm)

vollautomatisch

vollautomatisch

von allen Seiten

mit einer chaotischen Werkstück-Komplettfertigung

von allen 6 Werkstück Seiten

vollautomatisch

ohne Rüst-/Umrüstzeit

0 – 226 mm

vollautomatisch

R-C2 80 & R-C2 125 (L-140 bis L-235 mm)

vollautomatisch

vollautomatisch

von allen Seiten

mit einer chaotischen Werkstück-Komplettfertigung

von allen 6 Werkstück Seiten

vollautomatisch

ohne Rüst-/Umrüstzeit

0 – 226 mm

vollautomatisch

R-C2 80 & R-C2 125 (L-140 bis L-235 mm)

vollautomatisch

vollautomatisch

von allen Seiten

mit einer chaotischen Werkstück-Komplettfertigung

von allen 6 Werkstück Seiten

vollautomatisch

ohne Rüst-/Umrüstzeit

0 – 226 mm

vollautomatisch

R-C2 80 & R-C2 125 (L-140 bis L-235 mm)

vollautomatisch

vollautomatisch

von allen Seiten

mit einer chaotischen Werkstück-Komplettfertigung

von allen 6 Werkstück Seiten

vollautomatisch

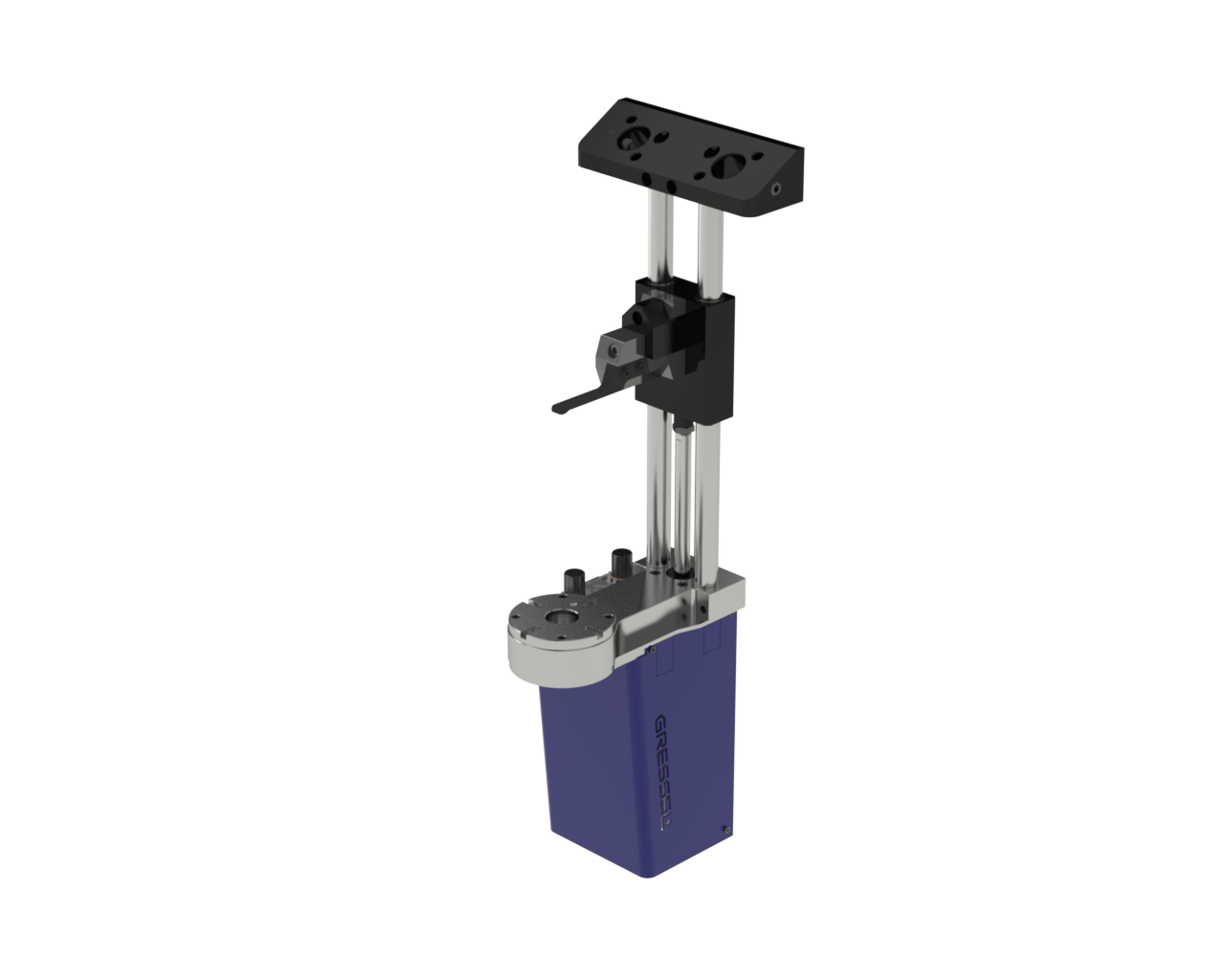

Vise automation

without setup/changeover time

Do your workpieces fit?

If your workpieces (max. 225 x 225 x 225 mm) can be clamped with the GRESSEL R-C2 vises, completely new possibilities open up to reduce the costs per workpiece.

Details about the R-C2 centering vises can be found in our catalogue.

Small batch sizeand unmannedproduction at night?

With an R-C2 automation, the operator can work extremely efficiently during the day without waiting time losses and build up work stock (run-in workpieces, blanks in the magazine, set-up tools) in the automation. This work stock is processed by the machine during the day and also unattended at night.

Great advantages with the R-C2 workpiece automation!

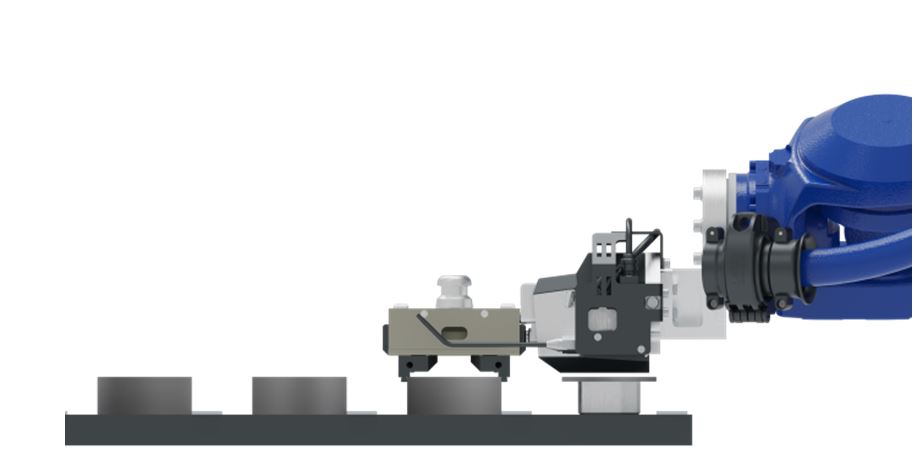

With the R-C2 system, we have succeeded in combining the advantages of workpiece direct loading and pallet automation.

- in the magazine the workpiece

gripped and clamped - the clamp with the workpiece is placed in the machine like

a pallet into the zero point clamping system.

This achieves three effects:

✓ the machine produces significantly more workpieces

✓ the time required of the operator at the automation decreases

✓ the setup times are significantly minimized

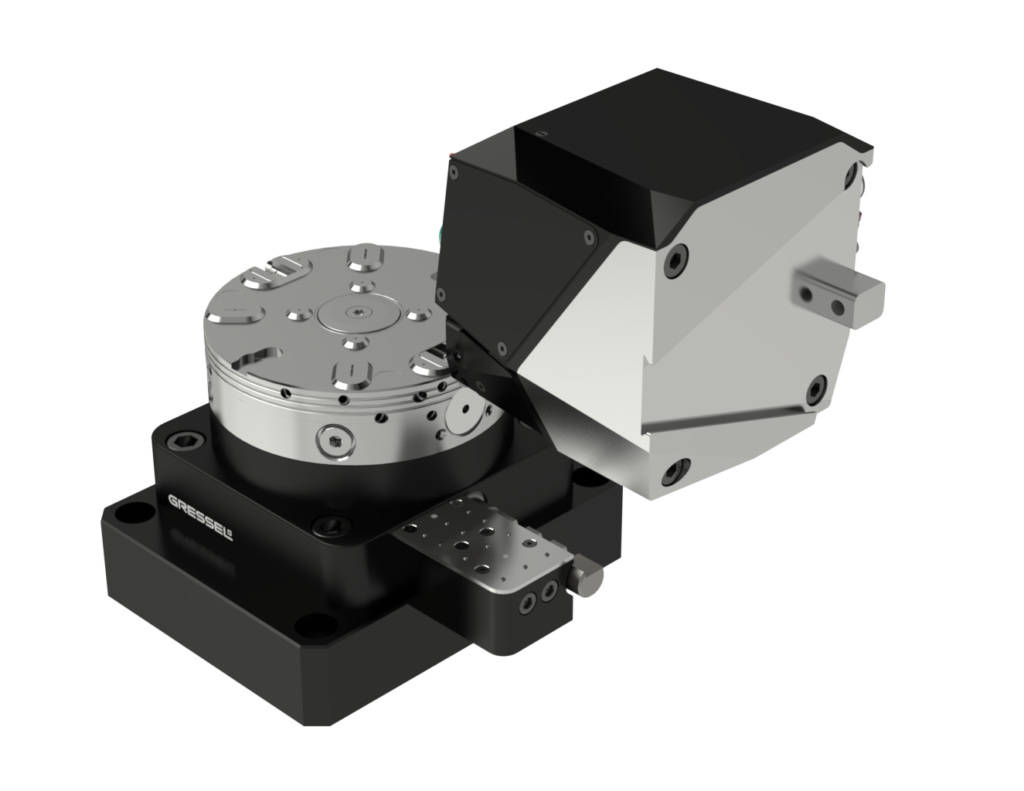

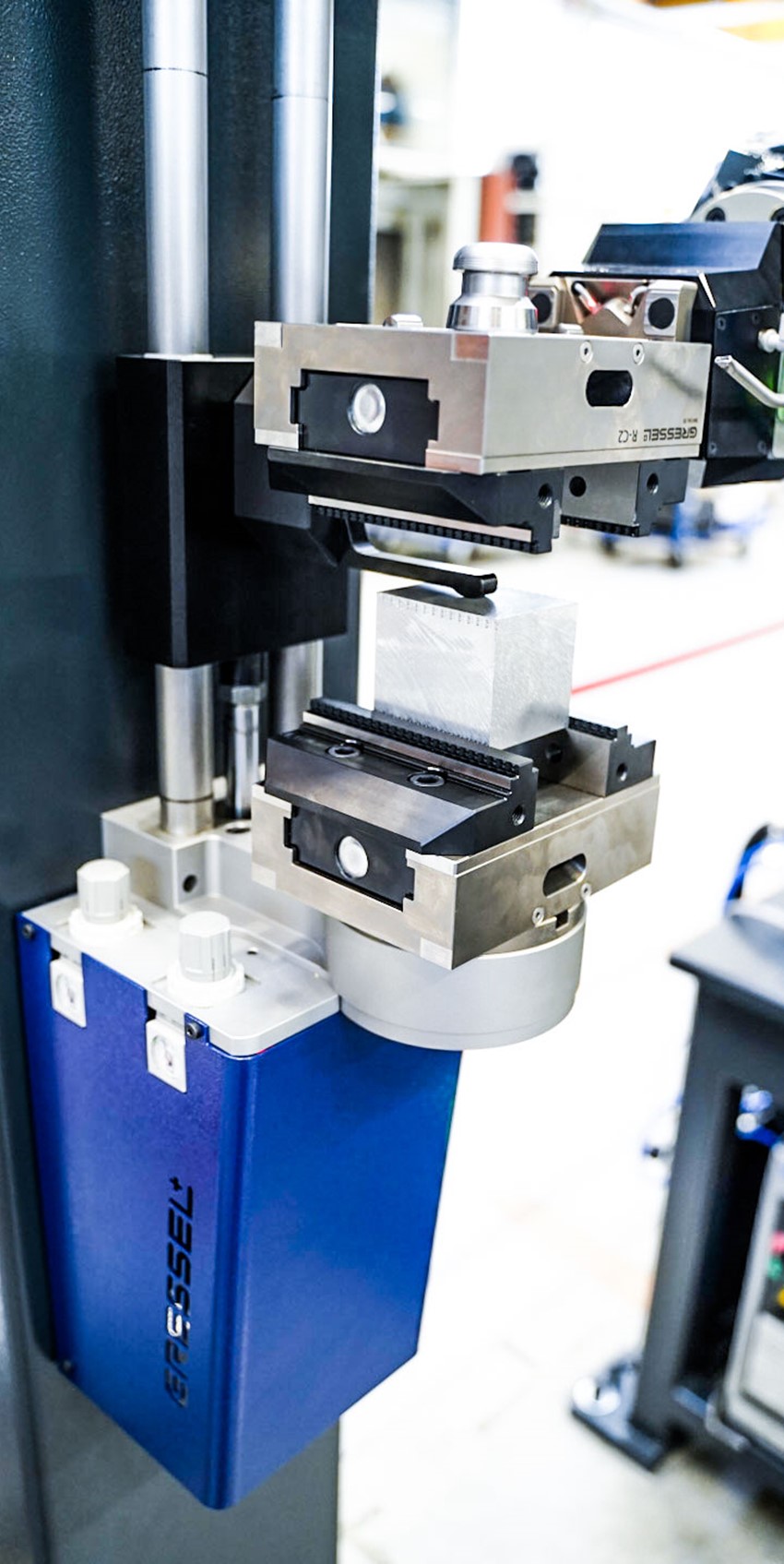

1 Vise automation - clamp and pallet automation in one

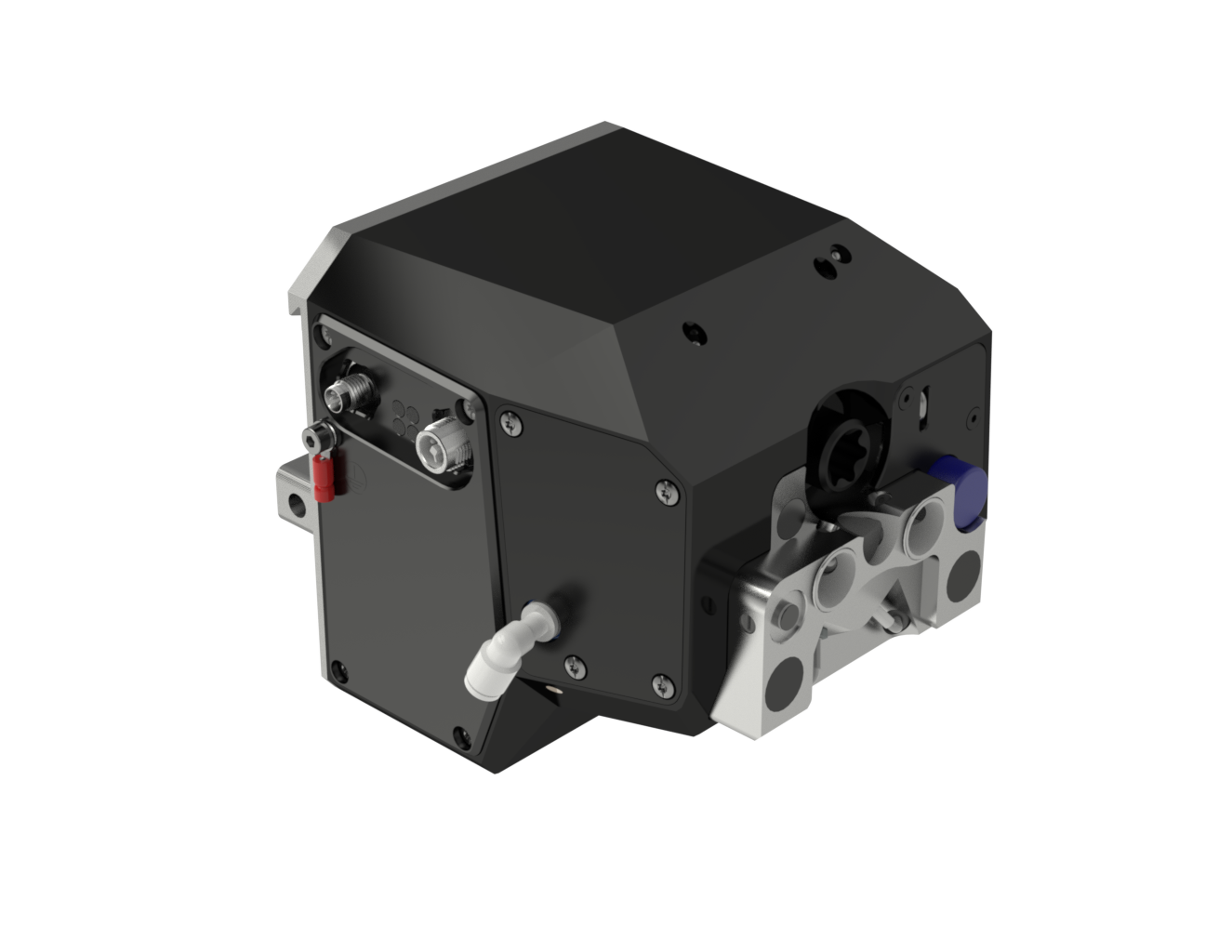

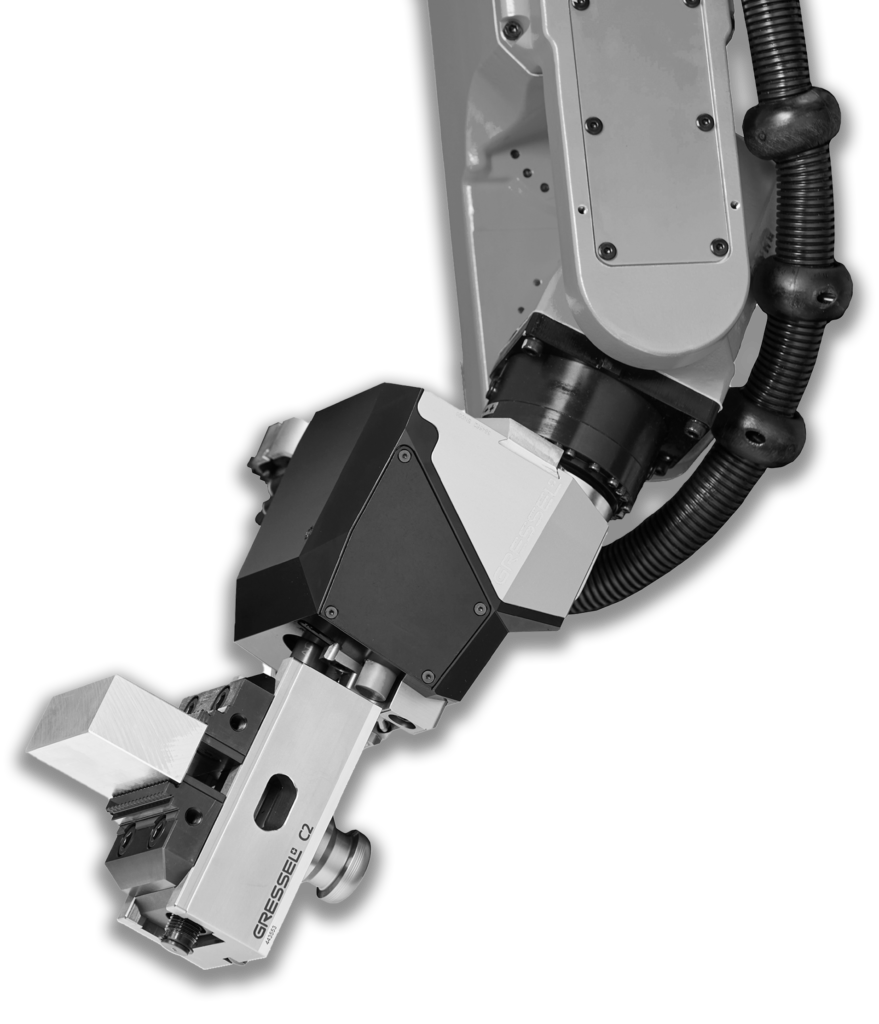

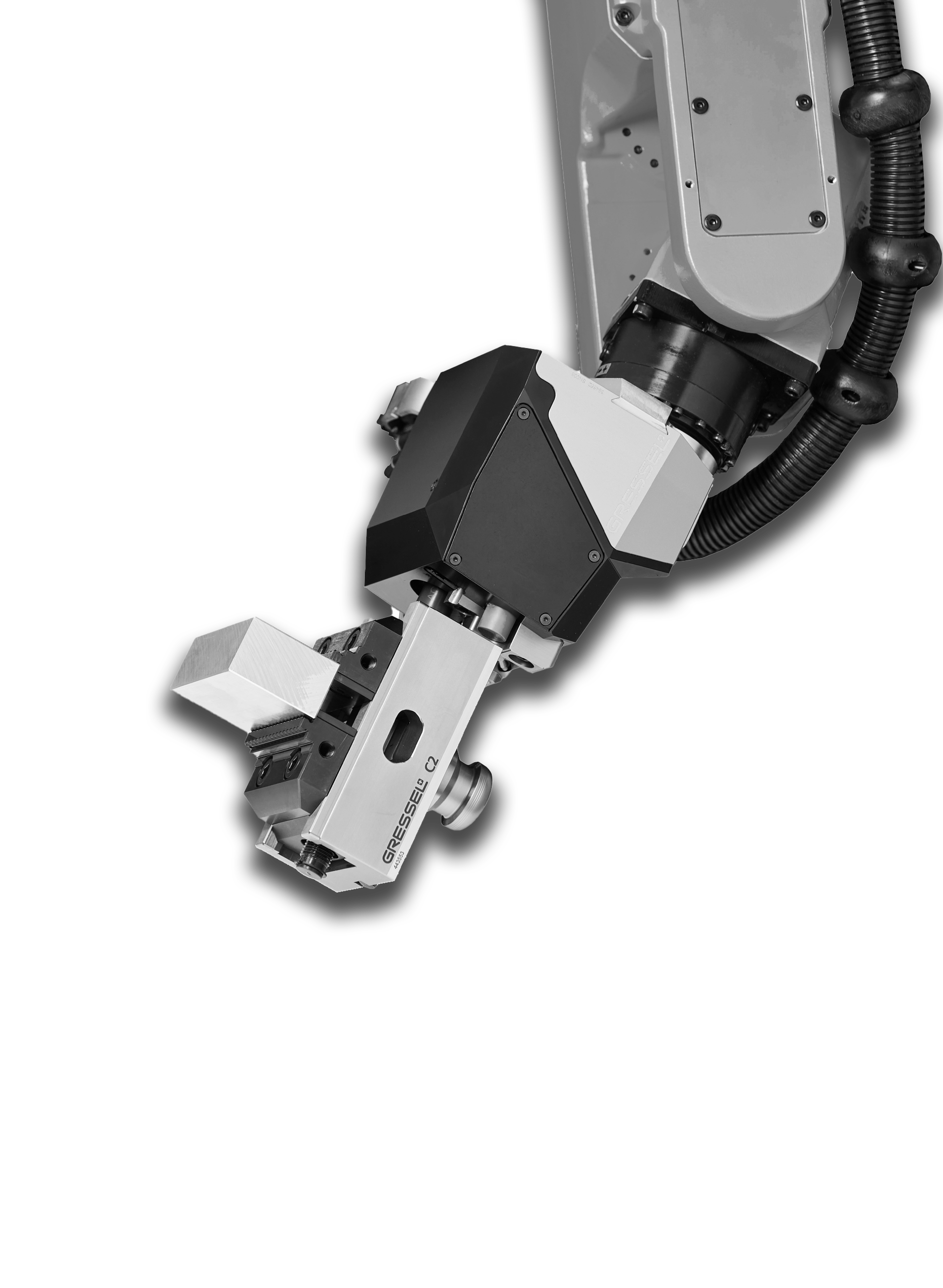

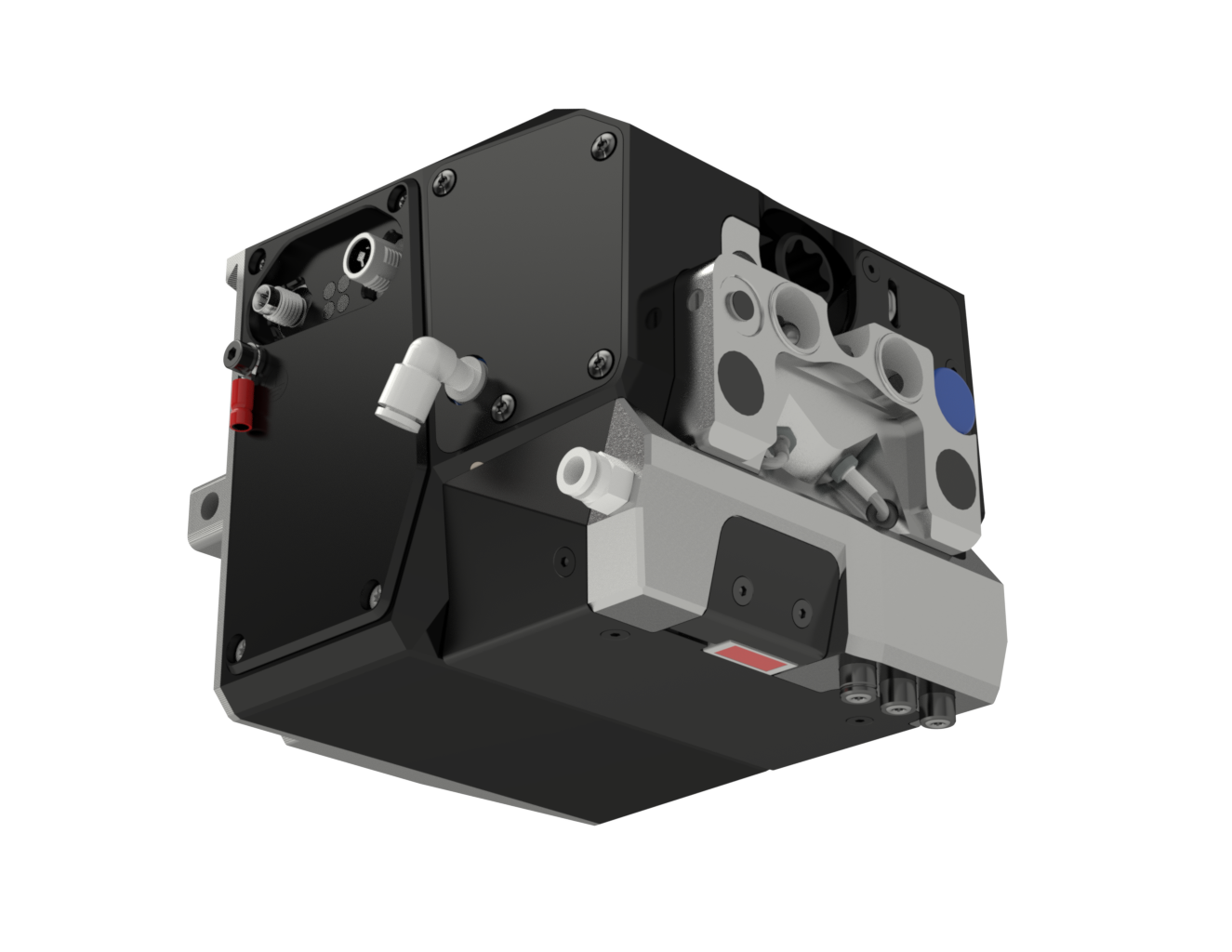

Robot clamping module R-C2 from GRESSEL

Fully automatic clamping range adjustment 0 - 226 mm

Fully automatic clamping force adjustment up to 30 kN

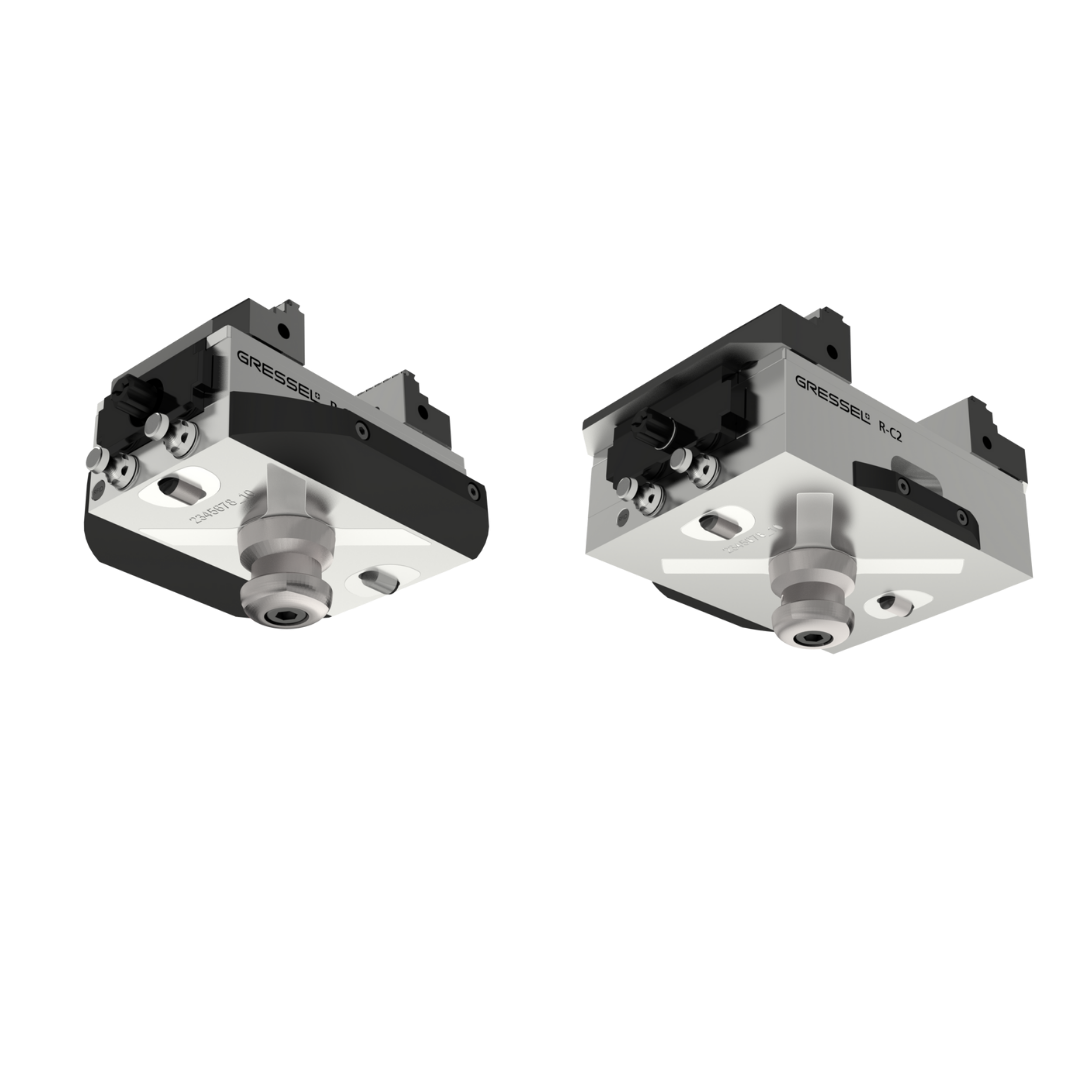

Centering clamp R-C2 80 L-140 & L-190 and R-C2 125 L-160 & L-235

Advantages that will

inspire you

GRESSEL R-C2 saves time and money!

✓Reduction in employee hours

R-C2 does everything by itself. Reduce employee hours at the machine and automation. Less time at the fixture means more time for other tasks and thus higher productivity of your employees.

✓ Unmanned milling machine automation

The proven GRESSEL clamping technology combined with the highest level of CNC automation. That is our GRESSEL R-C2. The result for you: maximum productivity and economic efficiency that is a pleasure to use.

✓ Clamps different products

Without changeovers or conversions, the R-C2 grips different products and feeds them safely and quickly to the machining process. No changeover times, no additional work steps.

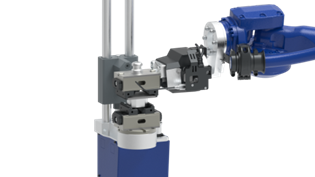

✓ 6-sided machining unmanned

Werkstück komplett fertigen auf allen 6 Seiten und das völlig automatisch und mannlos.

Our Designs

Workpiece automation R-C2

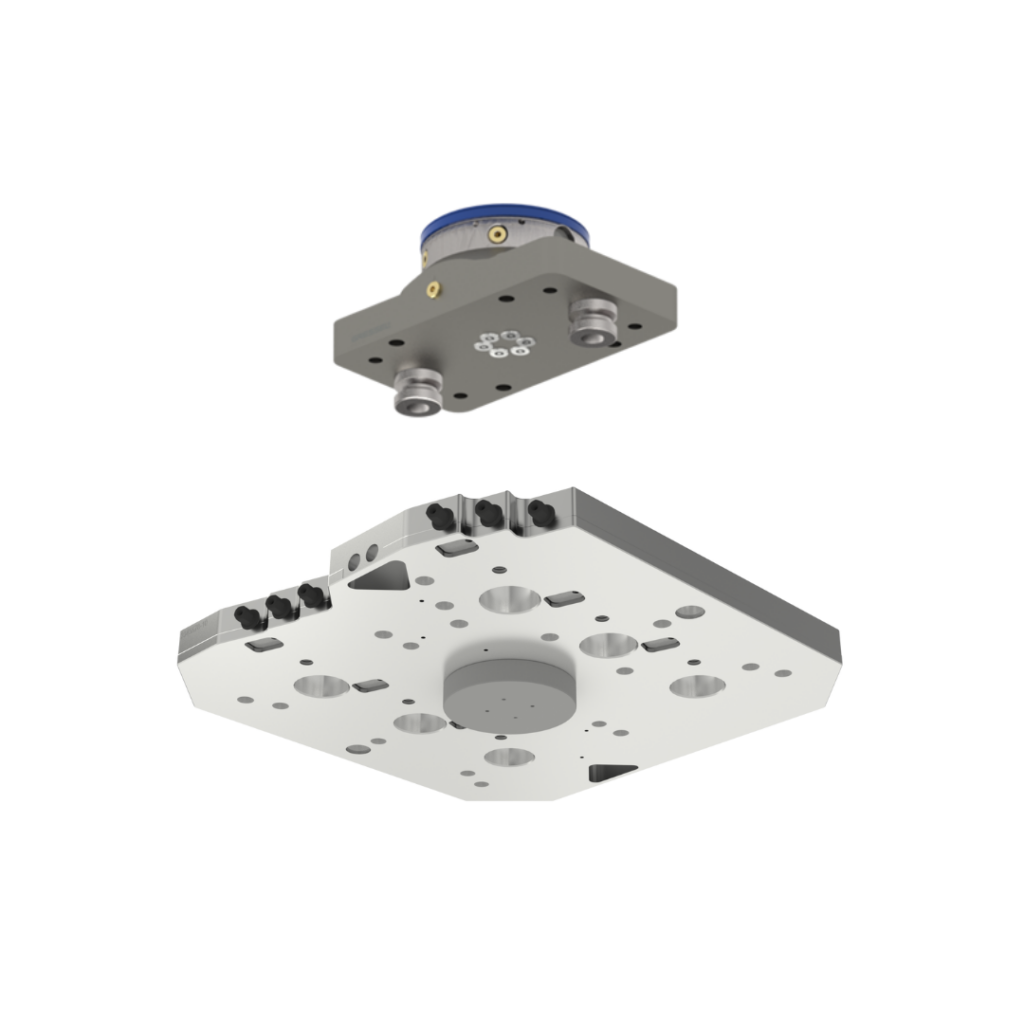

with media transfer

Automation without media feed-through in the machine table

Your CNC machine does not have a rotary union in the machine table? But you still want to automate your machine? Not a problem! With the GRESSEL R-C2 module incl. media coupling and the VERO-S console incl. media coupling you can automate without media feed-throughs in the table. You are thus spared an expensive retrofit of your CNC machine.

✓Simple retrofitting ofworkpiece automation

You can easily retrofit your existing machine with automation, since you do not need a media feed-through in the machine table.

✓ 6 pages of workpiece automation

With the R-C2 module incl. media coupling and the VERO-S console incl. media coupling in combination with the GRESSEL 6-sided station R-C2, you can produce complete workpieces unmanned.

✓ Highest productivity and maximum efficiency

Reliable GRESSEL clamping technology combined with the highest degree of automation. That is our R-C2! The result for you: Highest productivity and maximum economic efficiency, which is a pleasure.

World innovation:

6-sided production without set-up time

Workpiece 6 sides Machining unmanned

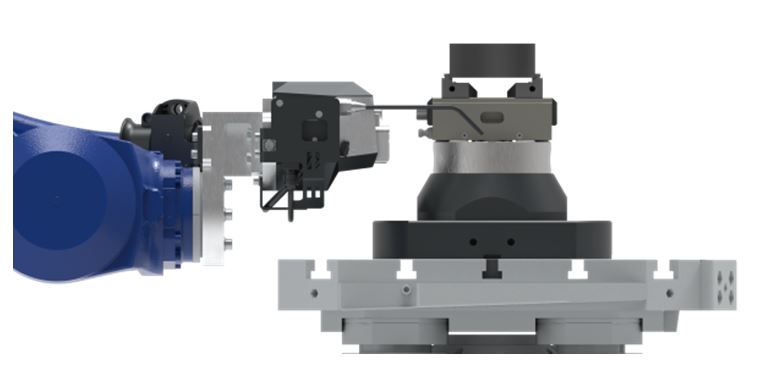

You want to go one step further with our R-C2? Produce workpieces flexibly on all 6 sides completely unmanned? Then simply combine our R-C2 module with our patented 6-sided GRESSEL R-C2 station.

✓ All in one – OP 10 and OP 20

OP 10 and OP 20 in one run. This is available in this form and

quality only from GRESSEL.

✓ 6-page machining

Machining 6 sides in one automatic operation without an operator means

faster production and more finished parts.

✓ 6 sides complete machining Benefit

– Simplification of logistics

– less storage space

– longer machine running times with the same storage size

– higher flexibility

The vise for OP 20 is inserted

The vise of OP 10 is positioned above it

Workpiece transfer with pressure finger for clean parallel workpiece support OP 20

Workpiece for OP 20 is clamped and pressure finger moves up after the R-C2 clamping module has clamped the workpiece fully automatically

5 sides automation example

6 sides automation example

-

R-C2 = Automation

of the future

- Chaotic 6 sides manufacturing

-

1 Vise

Automation

Workpiece automation R-C2

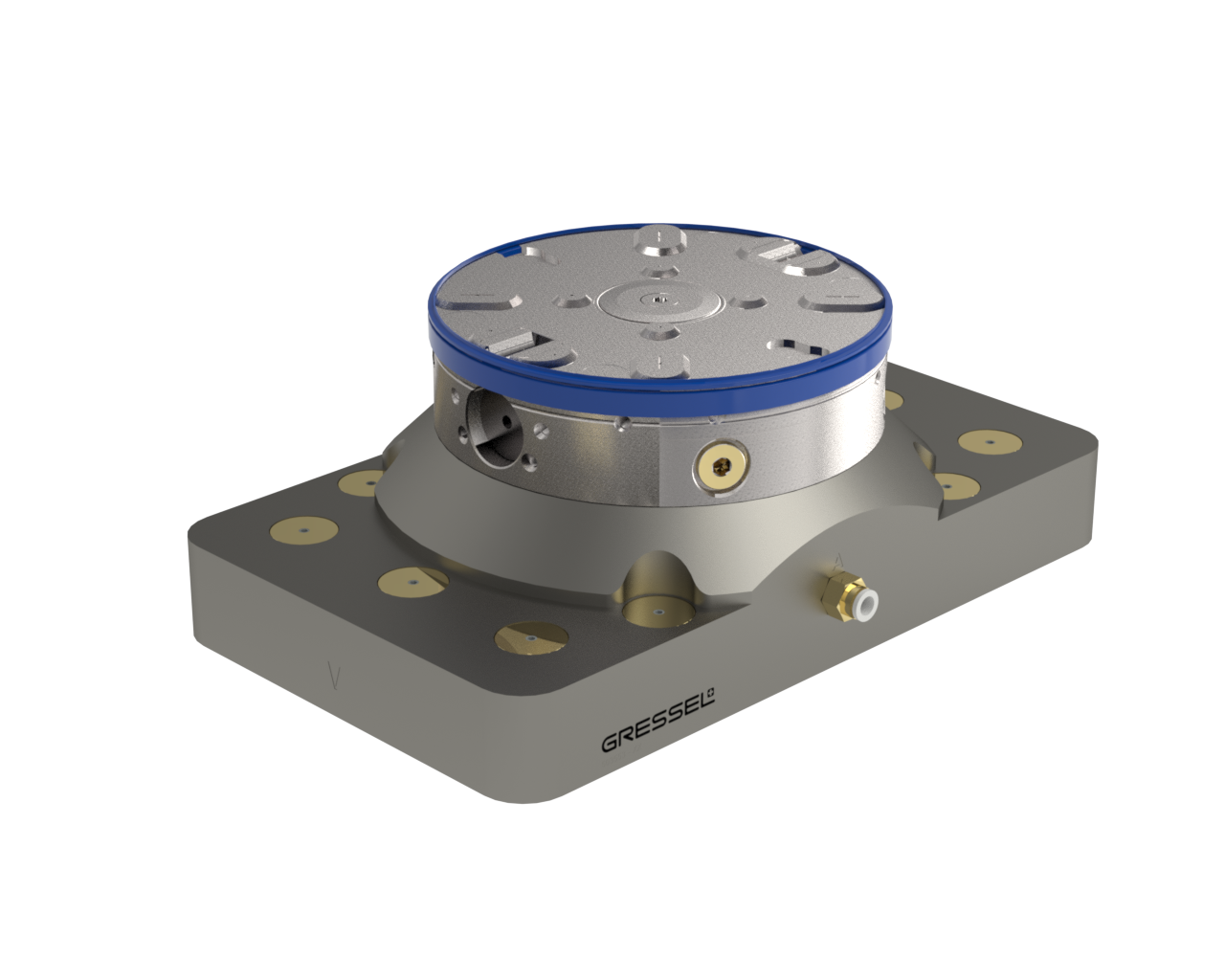

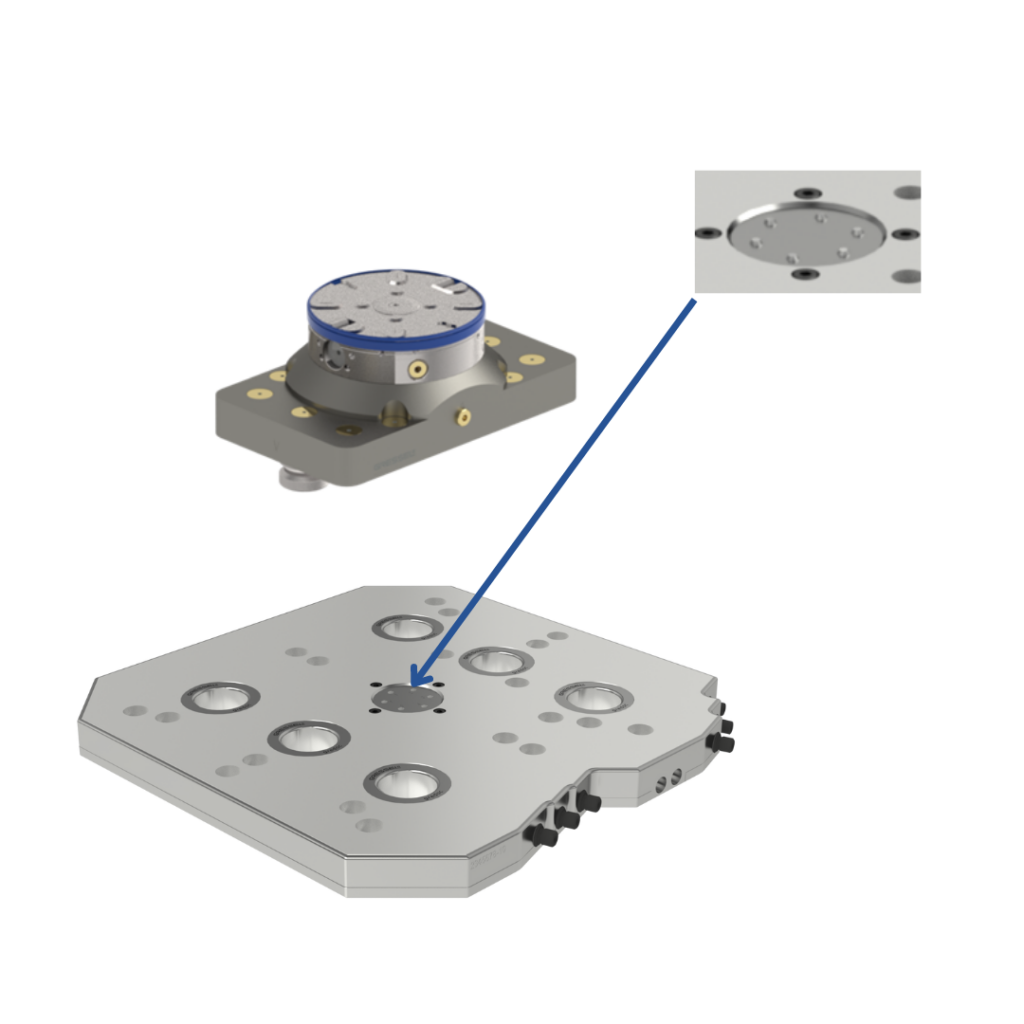

Zero point clamping system gredoc NSS with media transfer

In combination with zero point clamping system gredoc NSS with media transfer.

You want to go one step further with our R-C2? For example, automate the machine during the day or use it manually for single orders? Then simply combine your R-C2 automation with our zero point clamping system plate gredoc NSS with media transfer and you can easily work automatically or manually on the gredoc NSS plate and all this with almost no changeover times.

Recommended pin assignment:

| Funktion | Anschluss Spezifikation (Maschine) |

|---|---|

| Öffnen | max. 6 bar |

| Turbo | max. 6 bar |

| Reinigung Konus und Auflage innen | max. 6 bar |

| Schieberabfrage geöffnet | max. 2 bar |

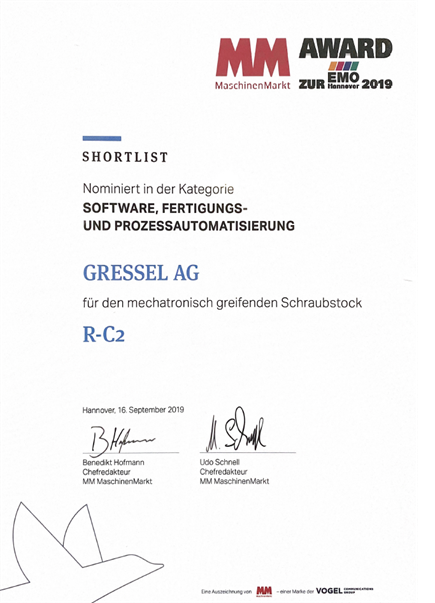

Certificates and awards

Innovative solution

Workpiece automation R-C2

Gressel workpiece automation R-C2 in action

Our R-C2 Partner

HALTER CNC Automation B.V.

Hogebrinkerweg 19

NL-3871 KM Hoevelaken

T +31 88 015 74 00

E info@haltercnc.com

Quick Load SRL

Via Fornace, 20

IT-40023 Castel Guelfo – Bologna

Zona industriale Poggio Piccolo

T +39 0542 670245

E info@quickload.it

Spinner Automation

Elly-Beinhorn-Str. 4

DE-71706 Markgröningen

T +49 / (0)7145 / 93 508 – 0

E sales@spinner-automation.de

STS Maschinendienstleistung GmbH

Friedrich-Münzinger-Straße 5

DE-72555 Metzingen

T +49 7123 30 77 91-0

E info@websts.de