Clamping technology for

Automation

We are your clamping technology partner for all types of automation.

Automation workpiece clamping technology

Automated loading and unloading of machine tools such as CNC milling machines or machining centers (machining centers) has now become the norm in many companies in the machining industry. Why? The lack of skilled workers and the pressure on costs and competition are increasing. Companies must therefore optimize their own processes in order to continue manufacturing economically.

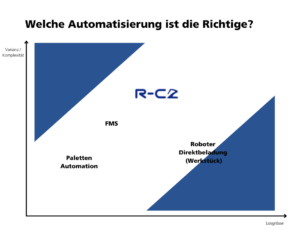

Whether you need clamping technology for a Pallet automation with small or large pallets, or a Workpiece automation with our R-C2 automation or a robot workpiece direct loading, we are your workholding partner for all automation types and show you how to efficiently reduce your setup times and get the maximum out of your production. Span us for you!

Clamping technology for automation: the most important facts in brief

What are the main advantages of pallet automation?

TOP 3 advantages are:

- Chaotic manufacturing is very possible

- High reliability of automation and unmanned production with loaded pallets

- The complexity is low

What are the main advantages of workpiece robot direct loading?

TOP 3 advantages are:

- Investment costs medium

- Stand area requirement mostly low

- Very high workpiece output (large-scale series production)

What are the special advantages of the GRESSEL R-C2 workpiece automation?

TOP 3 advantages are:

- Very little employee working time on the automation

- Chaotic production without setup/changeover time

- High workpiece output incl. Workpiece complete production on 6 sides

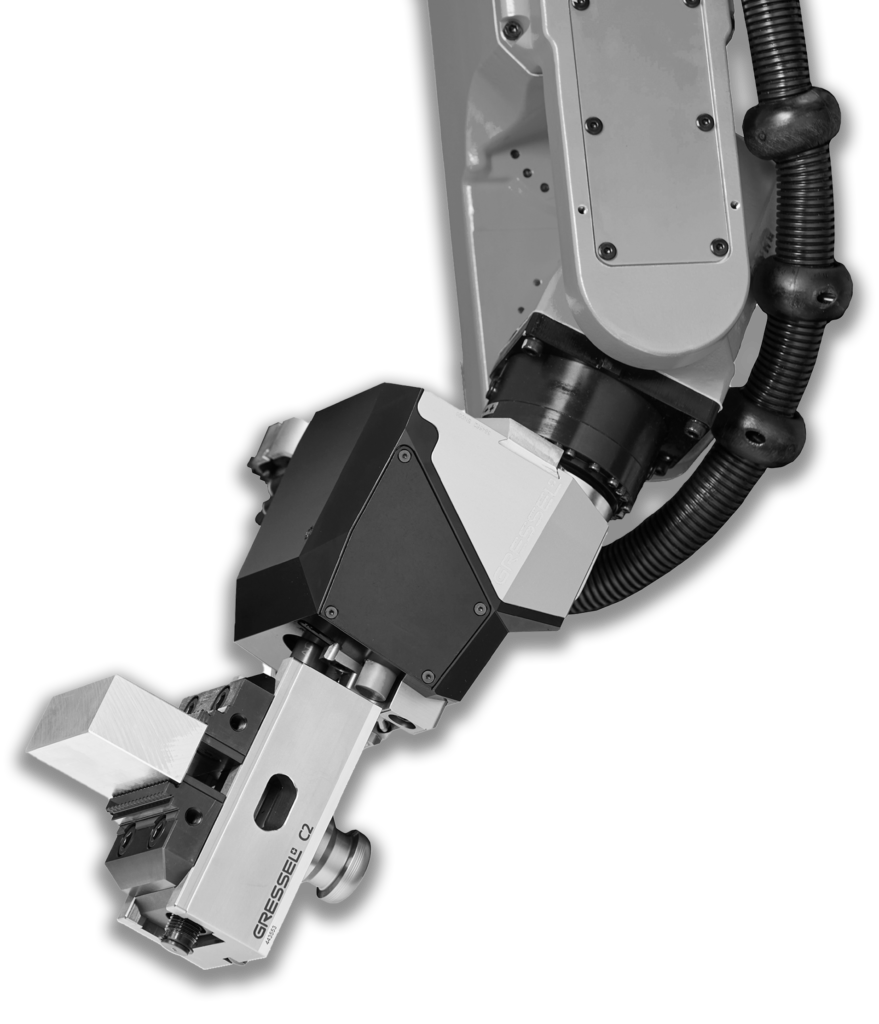

What automated workholding equipment does GRESSEL have for direct workpiece loading?

Single clamping vise:

solinos 65 hydraulic, solinos 100 hydraulic, gripos 125 hydraulic, gripos 160 hydraulic

5-axis clamp:

SC5X hydraulic

Double clamping vise:

D2 hydraulic

Paletten-Handling

SMALL PALLETS, MEDIUM PALLETS, LARGE PALLETS

- High utilization of the machine tool increases productivity

- Unit costs can be reduced enormously

- Suitable for single parts as repetition, or small to medium series

- New workpieces can be clamped during machining

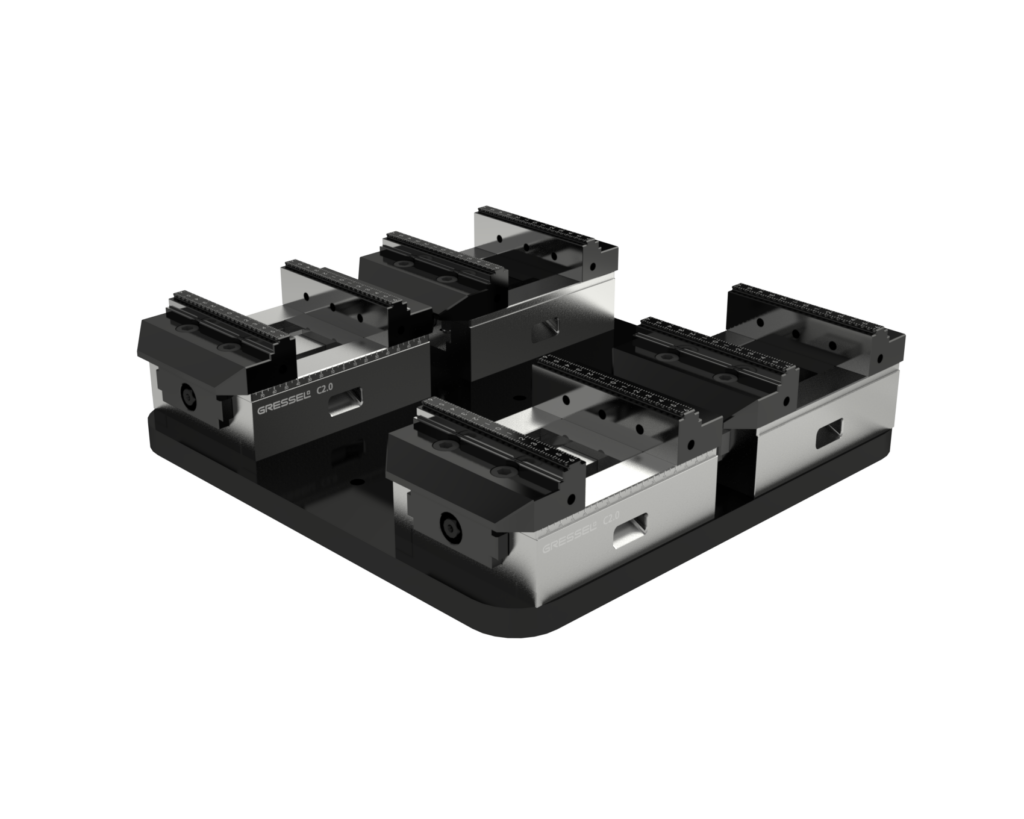

workpiece automation R-C2

Pallet automation and workpiece direct loading in one

- Only milling machine automation without set-up and changeover times

- Unmanned chaotic 6 sides manufacturing

- Clamping range automatically from 0 – 226 mm

- Mix with pallet handling possible

- Simple jaw production

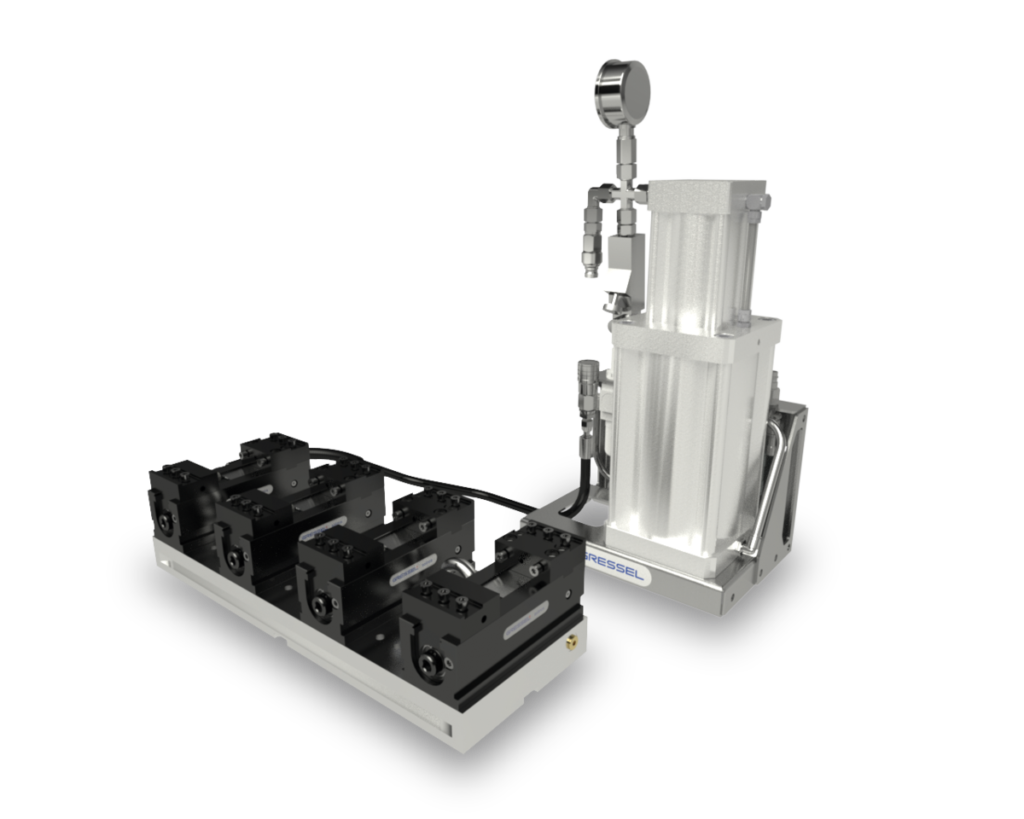

hydraulic clamping systems

The powerful clamping solution for every need

- Suitable for series production

- Easy connection to hydraulic vises, ready-to-install complete solutions

- Mounting possible on the left or right, also on existing infrastructure

- Simple and fast operation

- Large assortment and many possible combinations

- Pressure adjustable from 50 to 300 bar

- clamping technology for automation

- 5 + 6 side machining

- Future automation