Your benefits

With our wedge clamping elements

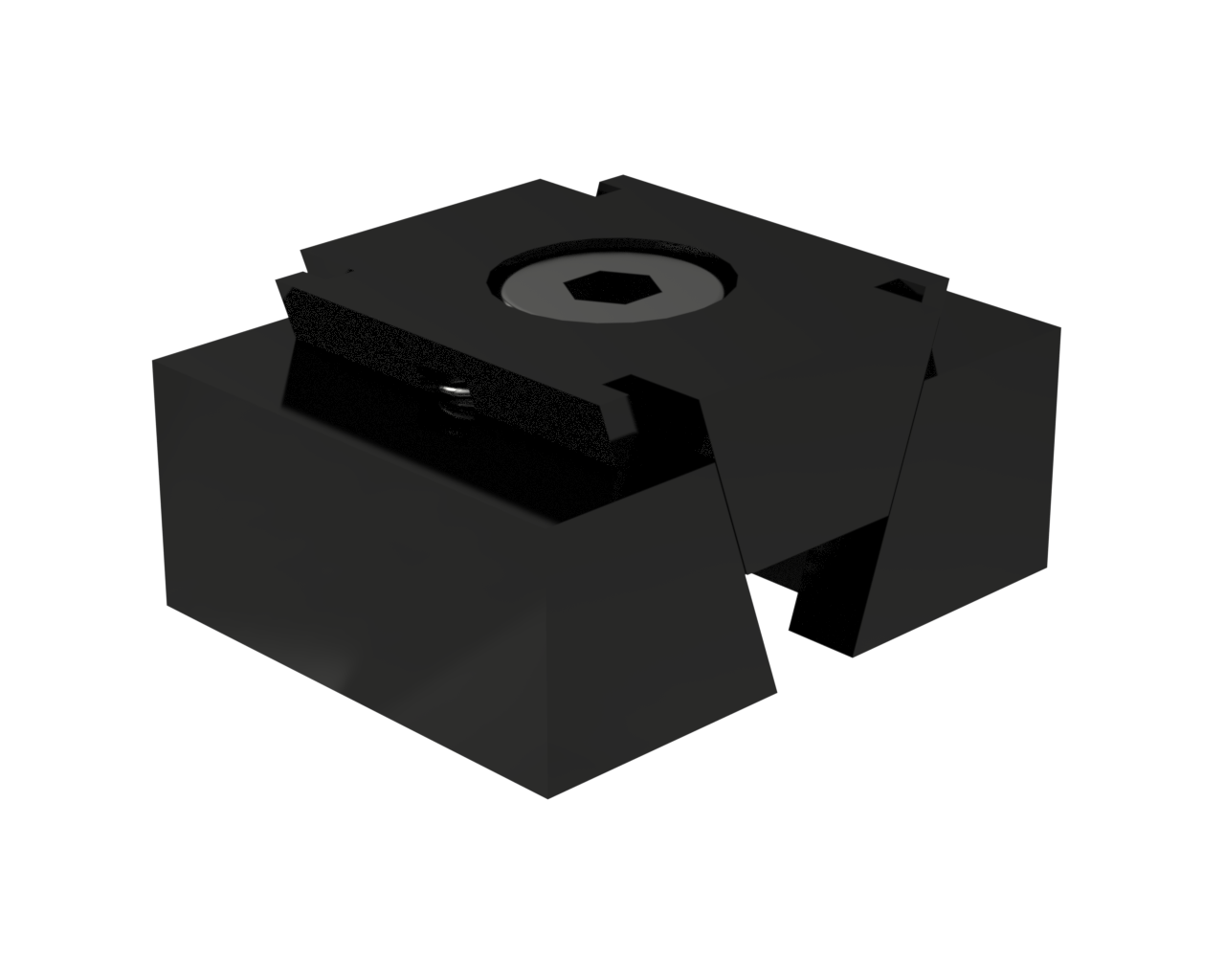

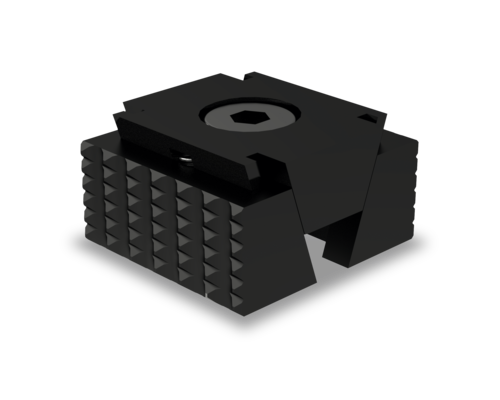

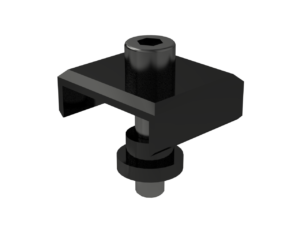

KSE

seven different clamping jaws

Clamping screw M8 (10 + 15 kN) and M12 (30 kN)

Clamping wedge with hardened wedge surfaces

Return spring inside (no chip accumulation)

Advantages that

will inspire you

✓ High clamping forces

Hardened wedge surfaces

High clamping forces of 10 or 30 kN

✓ Return spring protected from chips

internal = no contamination problems with chips

internal = no risk of damage

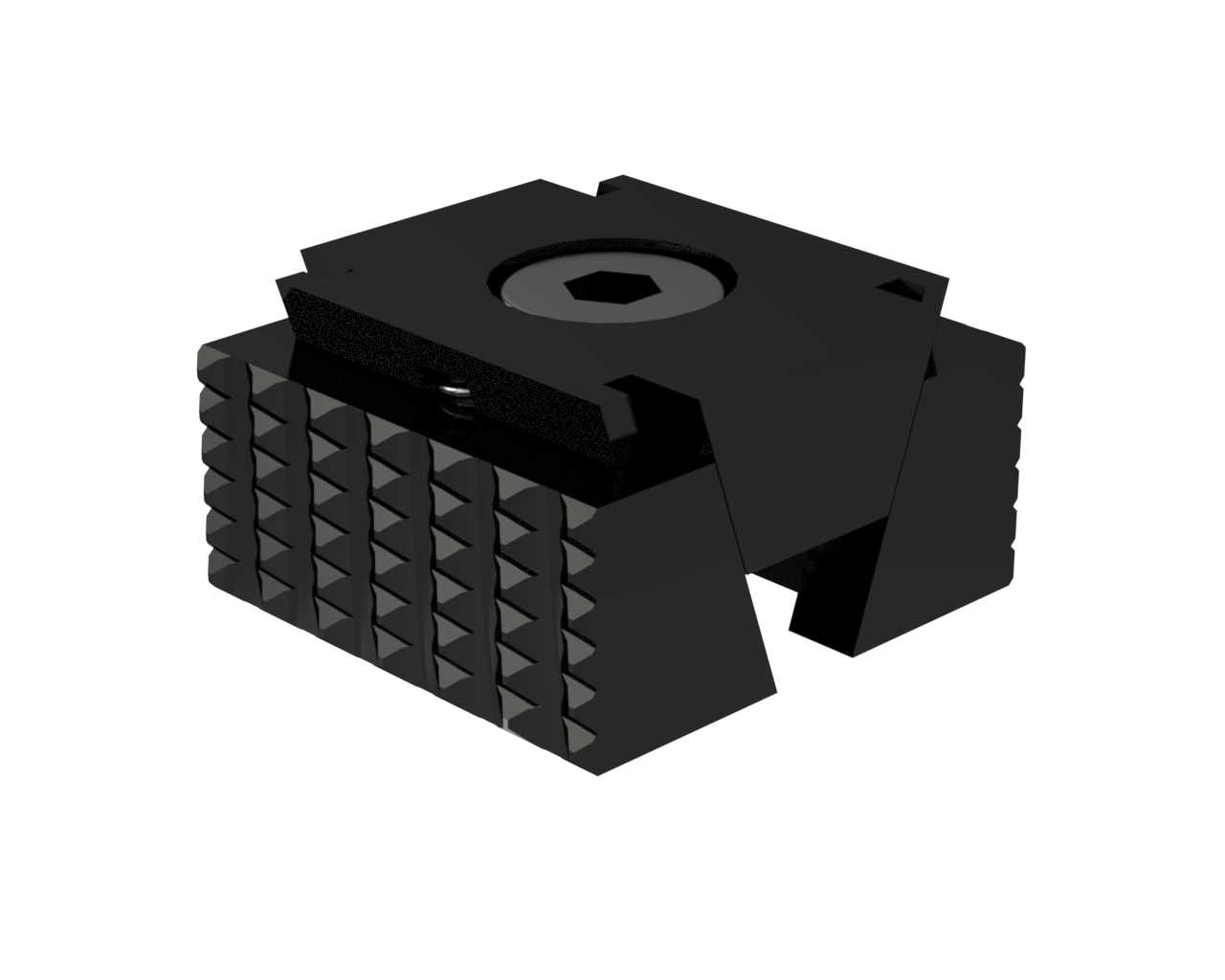

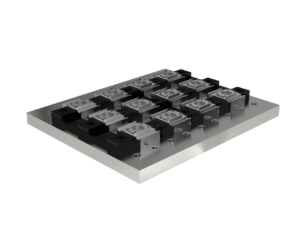

✓ Modular system

7 different sizes

Extensive range of jaws

✓ Various clamping screws

Our desings

Technical

information

Functional principle of the KSE wedge clamping element

Workpieces are clamped with an Allen key or torque wrench. By turning the clamping screw to the right, the middle clamping wedge is moved downwards. The two clamping jaws slide outwards through the wedge shape and clamp the workpieces. When the clamping screw is loosened, the center clamping wedge is returned to its original position by an internal return spring.

Clamping forces KSE

| Size | Max. Tightening torque | Max. Clamping force |

|---|---|---|

| KSE 21 with clamping screw M8 | 15 Nm | 10 kN |

| KSE 25 to 50 with clamping screw M8 | 20 Nm | 15 kN |

| KSE 40 to 50 with clamping screw M12 | 70 Nm | 30 kN |

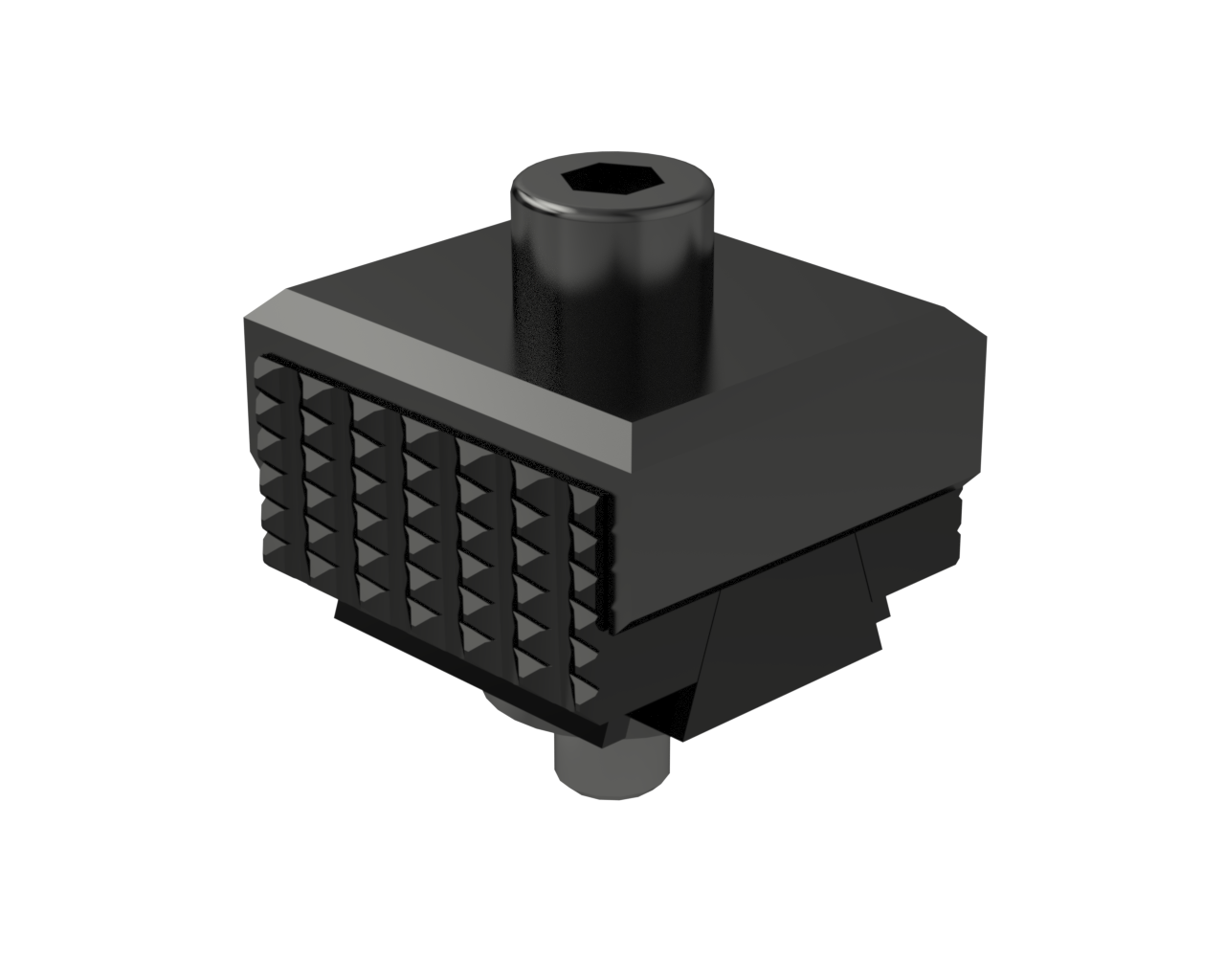

Mounting / Function

The KSEs have a central clamping screw. This is used both for mounting and for applying the clamping force. Mounting is done by screwing the clamping screw through the through hole in the KSE into a corresponding threaded hole on the fixture. As soon as the screw head is in contact, the clamping process starts. When the clamping screw is screwed in steadily, the base body moves downward and drives the two clamping jaws outward. The maximum clamping width is reached when the base body rests on the clamping device.

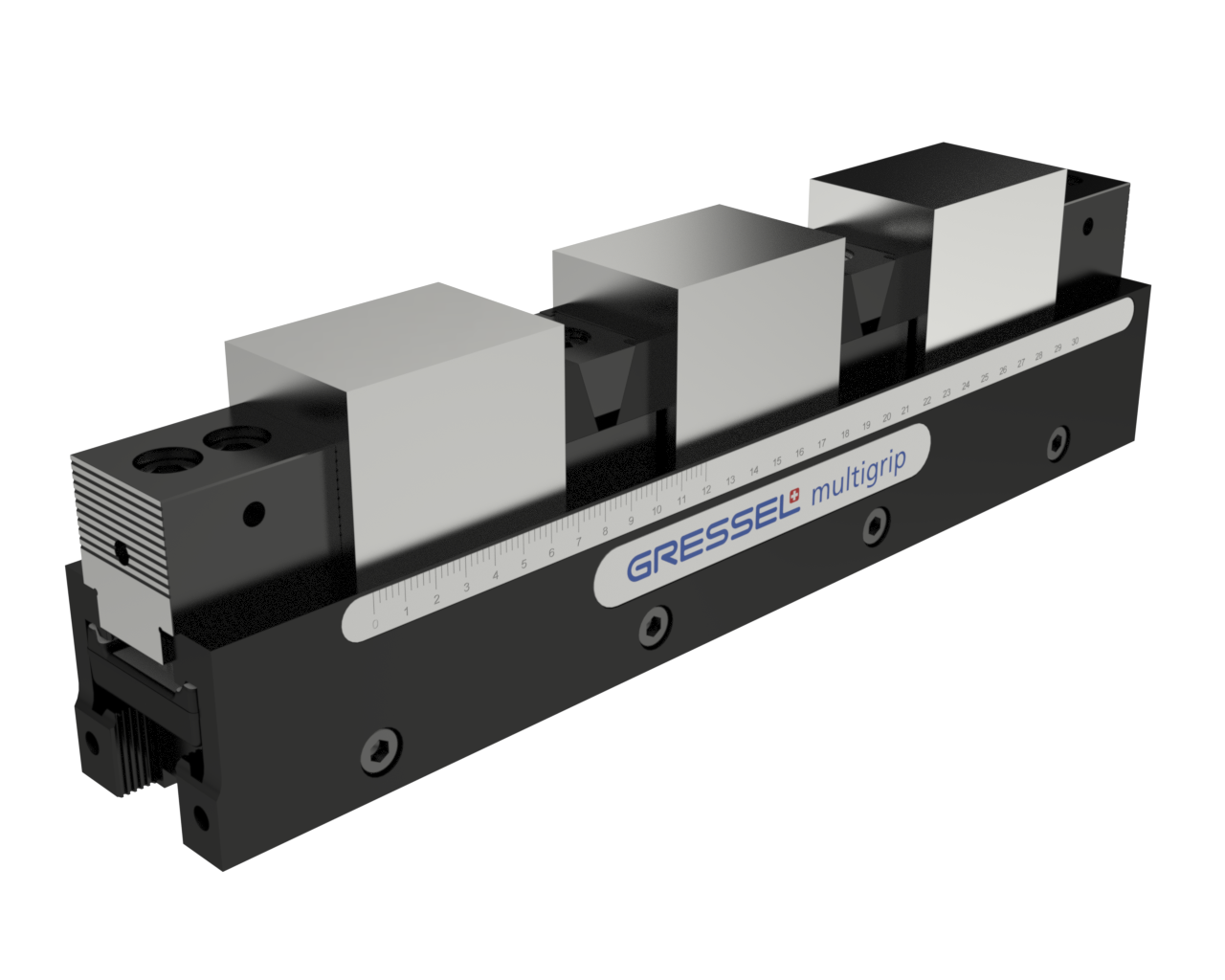

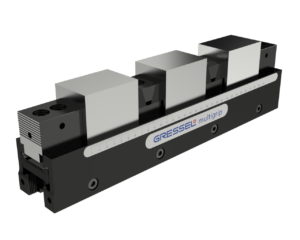

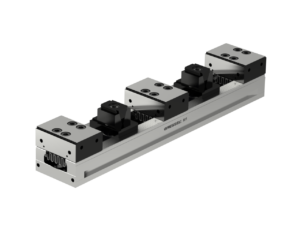

Gressel Wedge Clamping Element KSEin Action

- 2 years warranty

- Internal and protected spring

- Proven GRESSEL quality

Wedge clamping elements

Gressel pull-down kit NZS

+

=