Your benefits

With our

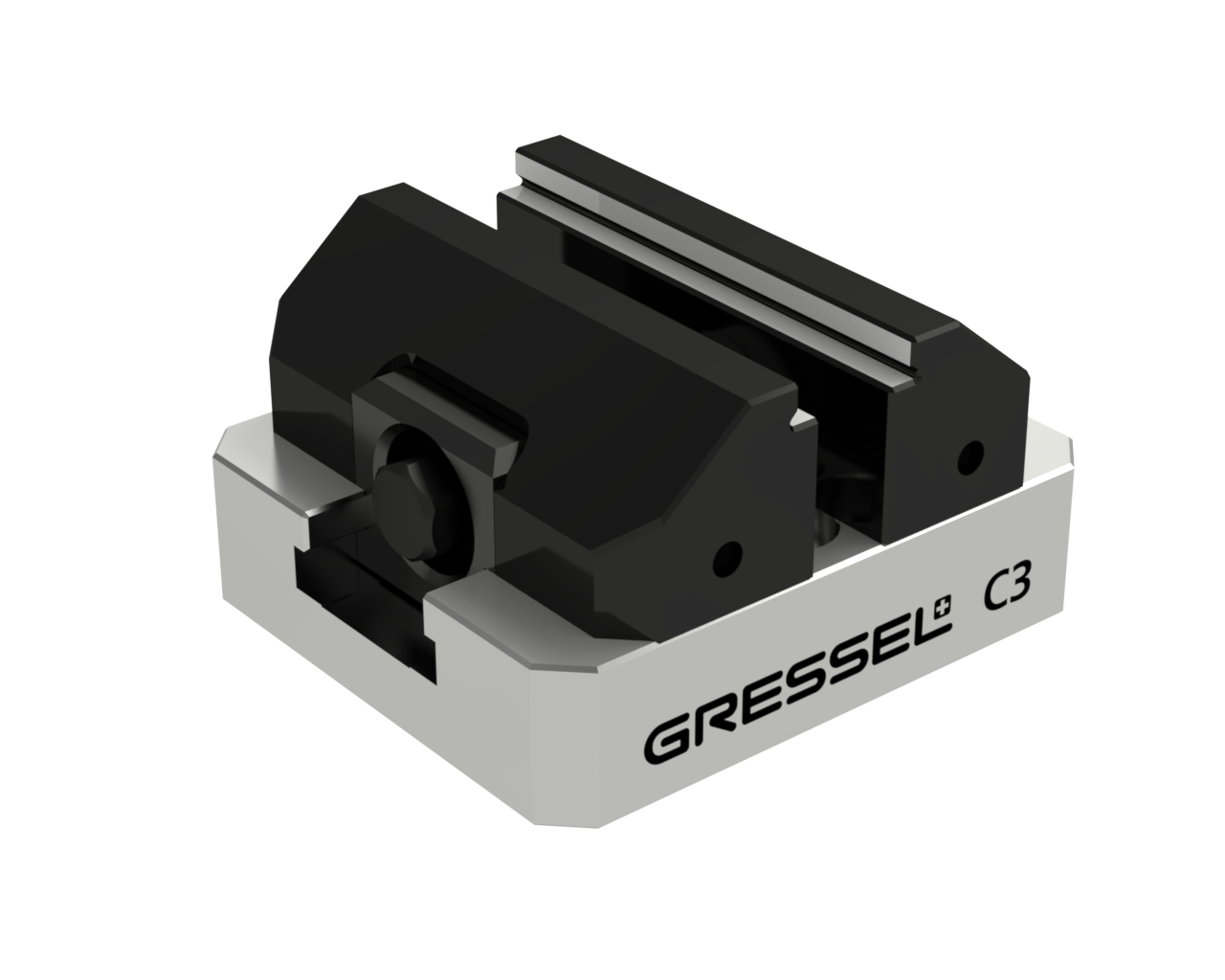

Centric vice C3

Easy handling for small workpieces!

5-axis C3 centric vice in mechanical design with high clamping force and quick jaw change system. Ideally suited for workpiece blank and finished part machining, multiple clamping on pallets, clamping towers and pyramids. As a small part centering vice , the C3is also excellent for various types of machine tool automation.

without tools

from all sides

(45 und 70 mm)

and wide clamping range

or workpiece automation

without tools

from all sides

(45 und 70 mm)

and wide clamping range

or workpiece automation

without tools

from all sides

(45 und 70 mm)

and wide clamping range

or workpiece automation

without tools

from all sides

(45 und 70 mm)

and wide clamping range

or workpiece automation

without tools

from all sides

(45 und 70 mm)

and wide clamping range

or workpiece automation

without tools

from all sides

(45 und 70 mm)

and wide clamping range

or workpiece automation

Best accessibility

Large clamping range –

grip or smooth step

Stainless and hardened base body HRC 45

Jaws quick change

without tool

High clamping force - 16 kN with 50 Nm

Compact design - Ideal for pallet automation

Advantages that will

inspire you

✓ Economy

fast set-up and easy handling

simple and fast conversion to enlarged clamping range

Short changeover times due to quick-change jaws

✓ Safety

shorter machining times due to higher cutting performance thanks to high clamping force

Safe clamping with GRESSEL grip jaws

Our designs

C3 L-80 smooth VS

with quick change jaw smooth

VS = increased clamping range

Width 45 and 70 mm

VS = increased clamping range

Width 45 and 70 mm

C3 L-100 grip VS

with quick change jaw grip

VS = increased clamping range

Width 45 and 70 mm

VS = increased clamping range

Width 45 and 70 mm

C3 L-100 grip VS

with quick change jaw LANG embossing profile

grip VS = increased clamping range

Width 45 and 70 mm

grip VS = increased clamping range

Width 45 and 70 mm

Centric vice C3

Important data at a glance

| Size | Clamping force | Dimensions (Base Body) | Clamping range max | Weight |

|---|---|---|---|---|

| C3 L-80 | 0 – 16 kN | 80 x 70 x 20 mm | 0 – 57 mm | 0.9 kg |

| C3 L-100 | 0 – 16 kN | 100 x 70 x 20 mm | 0 – 77 mm | 1.1 kg |

- 2 years warranty

- Jaws quick change

- Proven GRESSEL quality

Four clamping options

The right clamping device

for your tasks

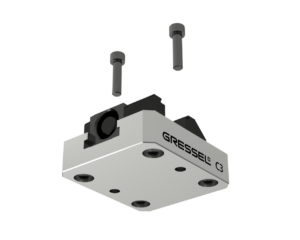

The C3 offers the following options for mounting on the machine table integrated in the centering vice. Optional: positioning and mounting holes on customer request.

Clamping with 2 screws from above through the base body

Clamping with 2 screws from above through the base body. Alignment can be done via Ø12 H7 precision holes

Both versions are equipped with the mounting holes for the

Zero Point (LANG), Solid Point (HWR), RockLock (5thaxis) and others.

(HWR), RockLock (5thaxis) and others.

The C3 L-100 is equipped with a SCHUNK VERO-S NSE mini

interface This allows the clamp to be used on NSE mini modules as well as clamping stations with integrated anti-rotation V1.

Gressel centric vice C3 in action

Video Playlist

1/5 videos

1

GRESSEL C3 – Zentrischspanner / centric vice

01:08

2

Small, strong, robust – centric vice ZSG mini makes a big difference

03:22

3

BEHIND THE SCENES OF C3 – Zentrischspanner

00:44

4

GRESSEL C3 – Zentrischspanner: klein, stark, robust – der C3 packt kräftig zu!

01:25

5

GRESSEL C3

00:52