Vises

Machine vices or single vices for craft and industry.

Machine vice

With our machine vices, you can clamp workpieces in milling machines so that your machining is even more precise and accurate. Find the right vise in our programm. GRESSEL has a large range of jaw widths from 40 mm to 160 mm and clamping force from 15 kN to 60 kN.

Vise: the most important in a nutshell

How do I find the right vise?

Let our distribution engineers advise you and then test our machine vice on your machine.

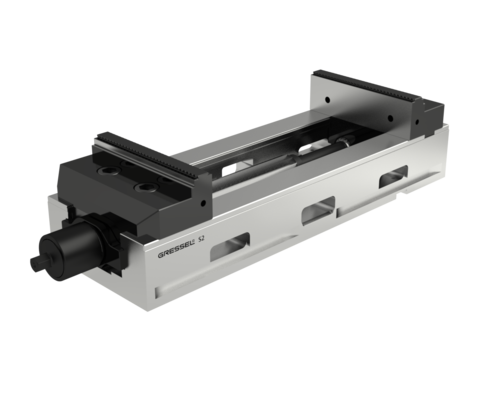

Which single clamping vise do I use for pallet automation?

The single clamping vise S2 has a low base body height and thus little weight for pallet handling. The solinos single clamping vise and our SC2.0 fixed jaw clamp from the C2.0 modular program are just as suitable.

In which sizes is the machine vice gripos available?

Jaw width 100, 125 and 160 mm

What are the advantages of a fixed jaw clamp for finished part machining?

Due to its continuous slot in the base body and the matching fixed jaw, you get a very good angular accuracy.

Machine vise gripos

The precision metalworking vise

- By means of a hand crank there is a quick adjustment

- Clamping force continuously adjustable from 4-40 kN

- Known 160°lever quick clamping

- Easy cleaning by demounting the complete spindle unit

- Proven on the market for more than 30 years

Machine vise grefors

Is part of every workshop equipment

- Proven high-pressure clamping system

- Clamping through only one turn of the crank

- Clamping force continuously and manually adjustable up to 60 kN

- Simple and quick adjustment of the clamping range

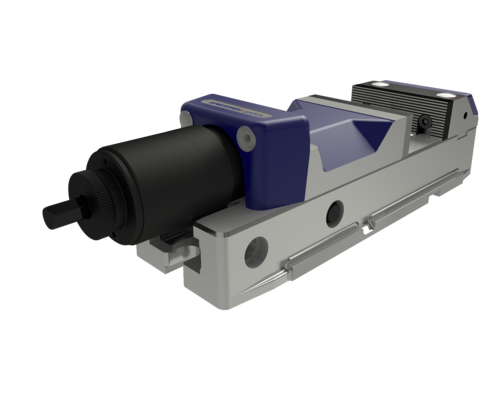

Single vise S2

The single clamping vise that convinces

- No bending of the base body during clamping

- Modular diversity for pallet automation

- Raw and finished part machining with one jaw

- High flexibility of application and use

- Less installation space in the machine, more space for the workpiece

Single vise solinos

The solinos is also available in hydraulic version

- Small part single clamping vise

- Low base body

- Modular construction kit for machine runtime increase

- 3-axis as well as for 4-axis and 5-axis machining

- 2 years warranty

- Modular clamping technology

- >300 Combinations