Your benefits

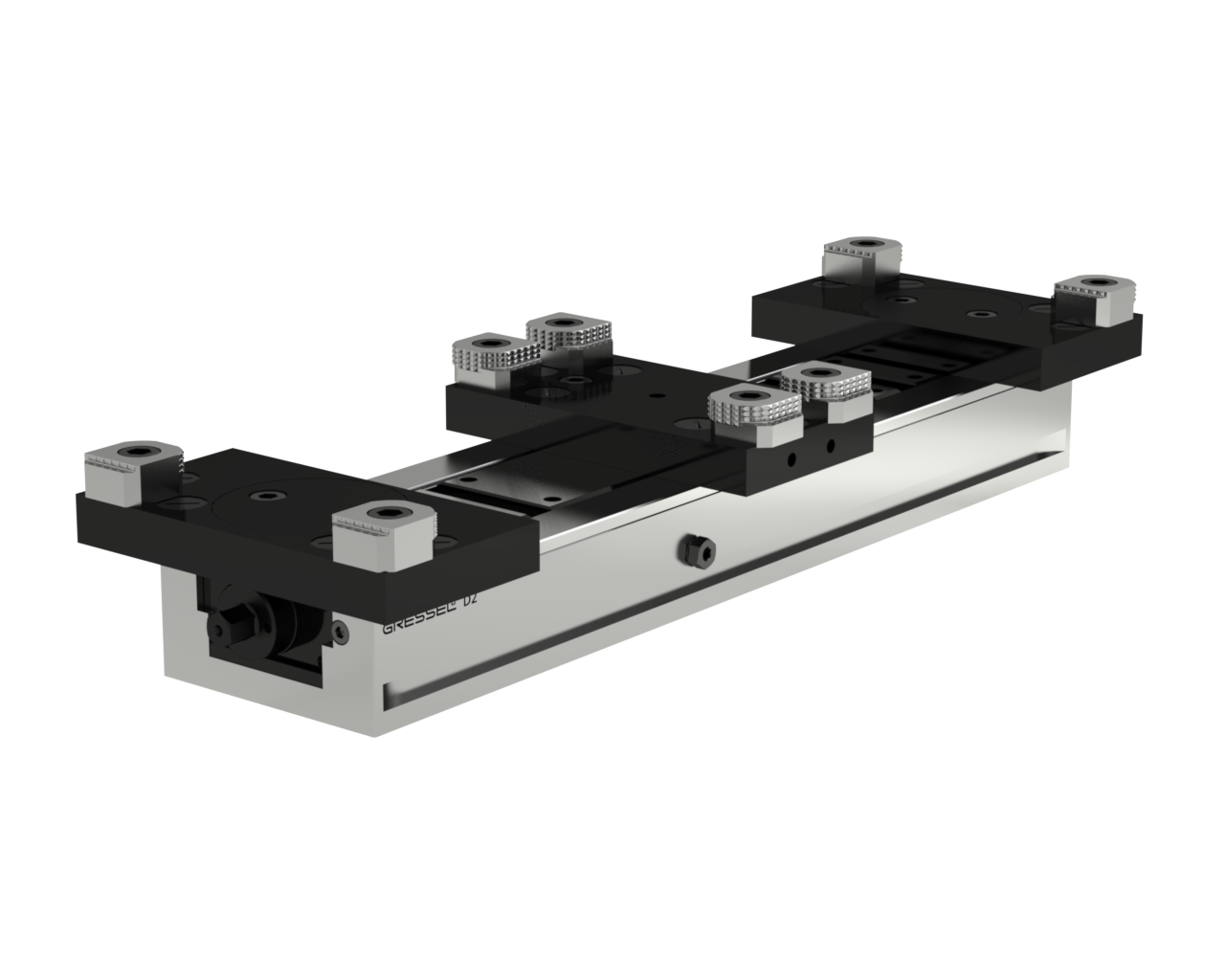

with our double vise D2

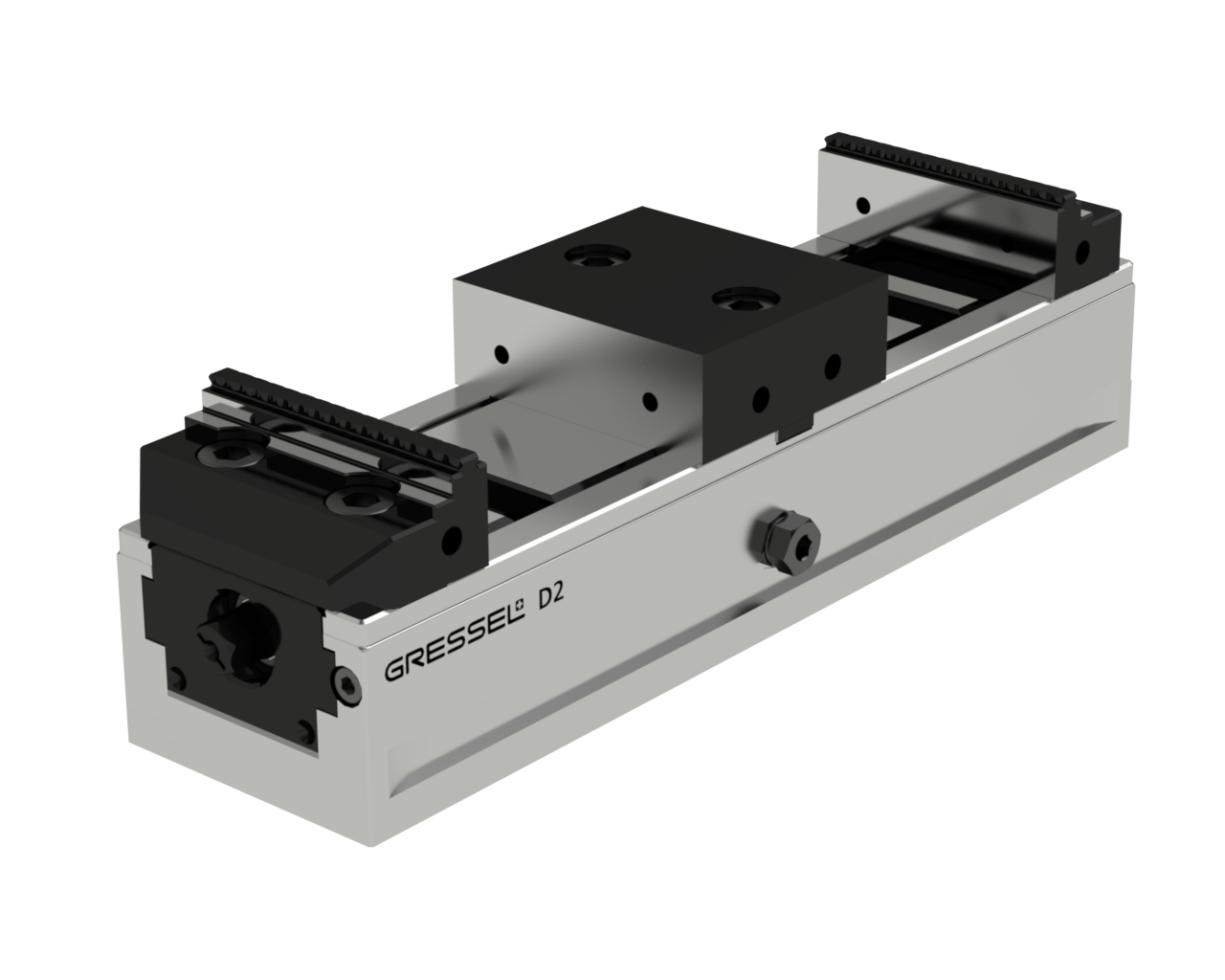

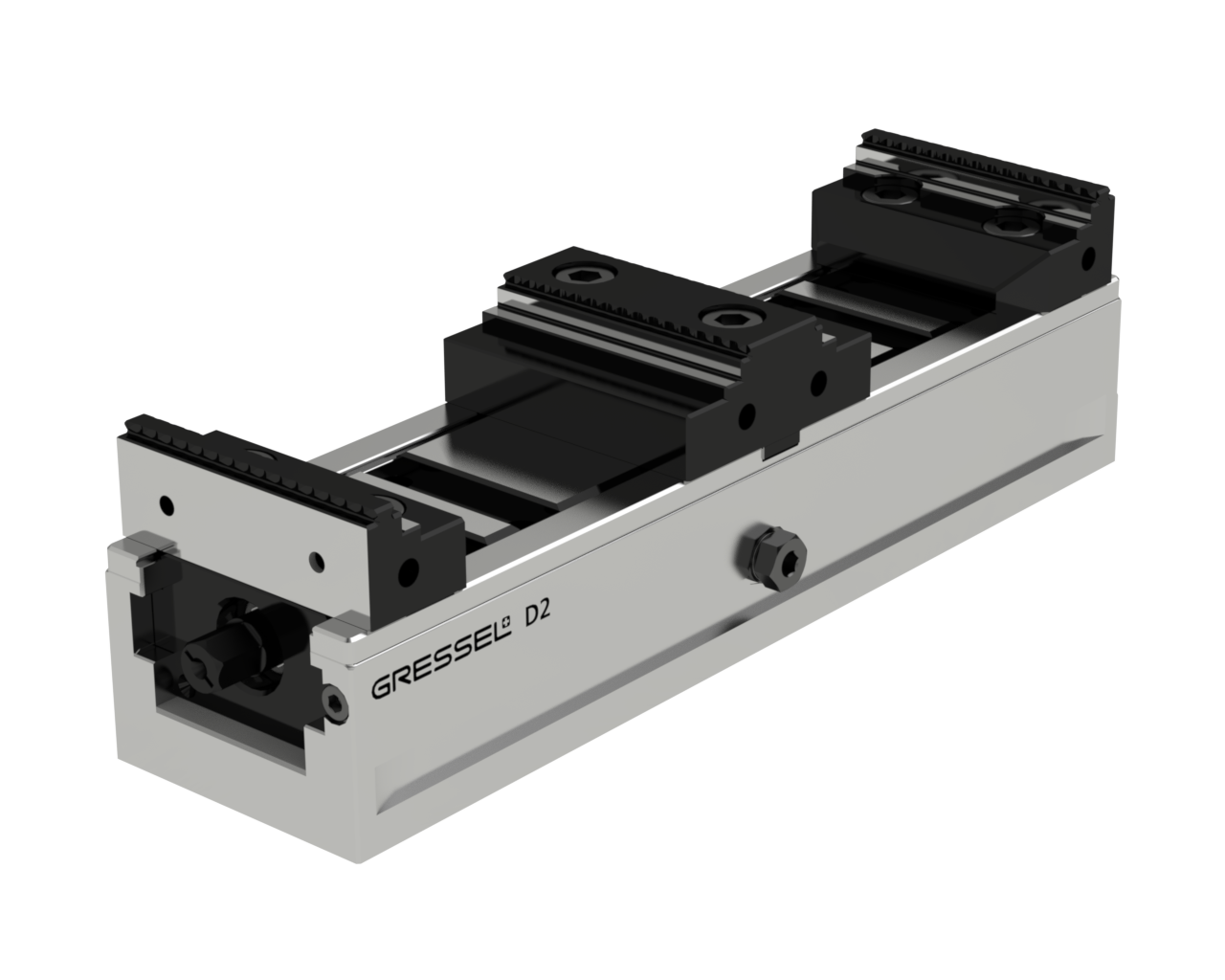

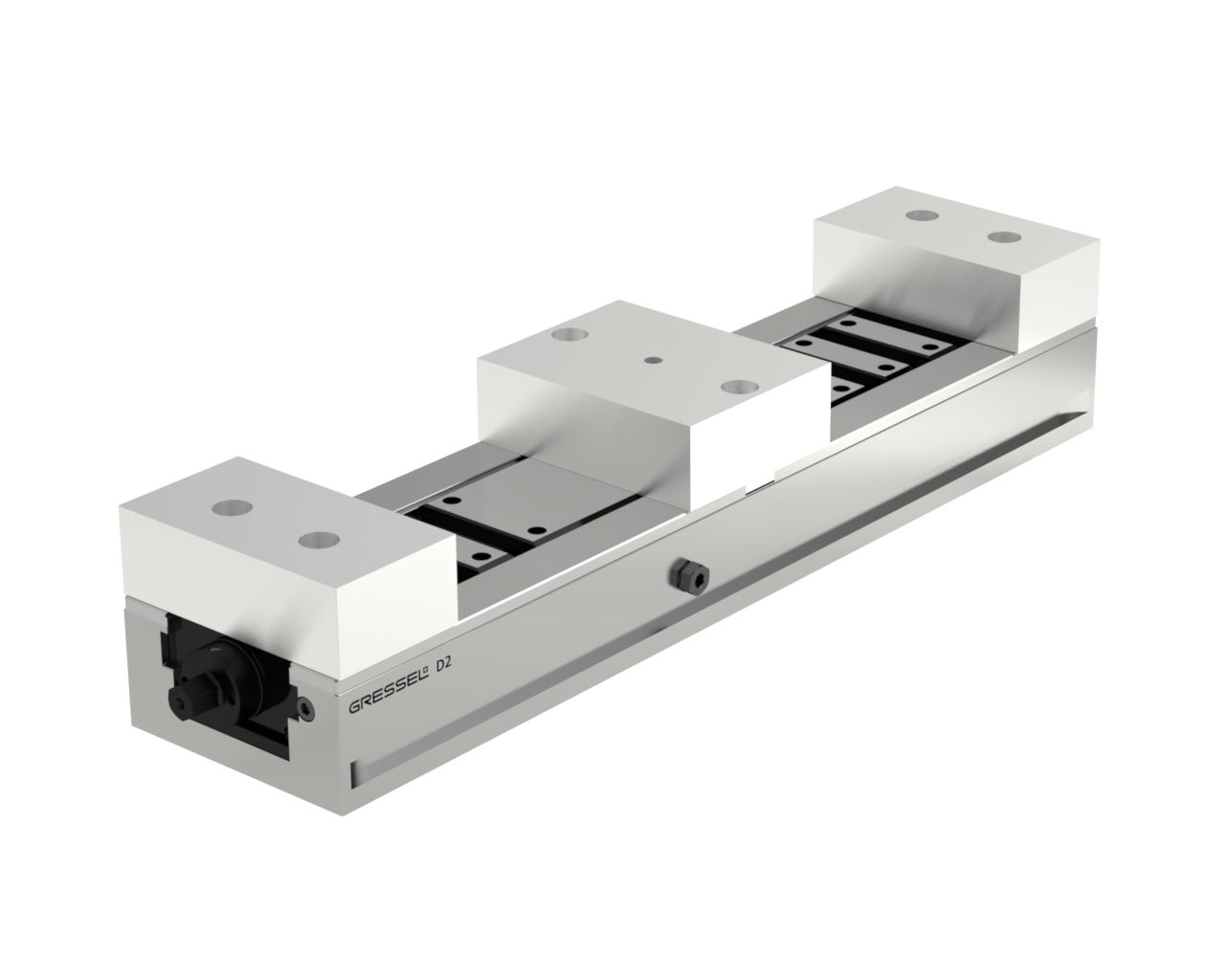

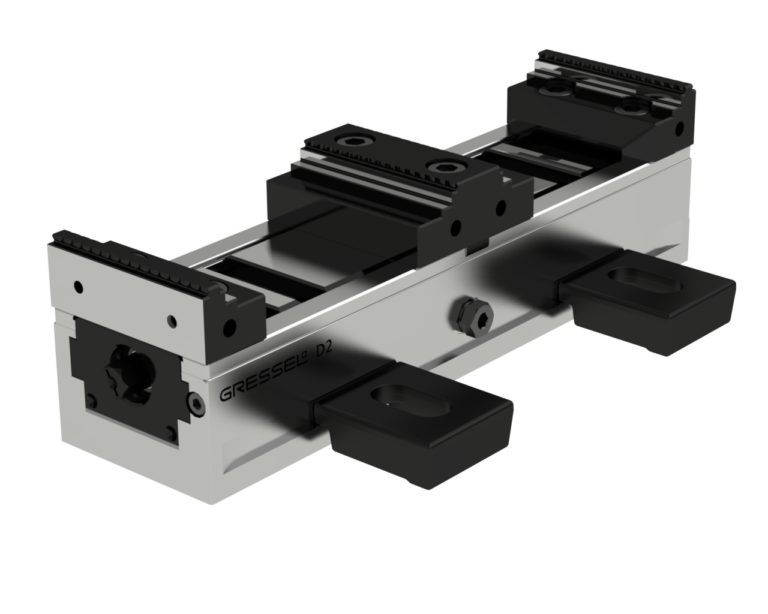

The manual double clamps D2 from GRESSEL are specially designed for demanding continuous use on clamping tombstones or pallet automations. Due to the nickel-plated base body, these clamps are perfectly protected against corrosion. As part of the large C2.0 / S2 / D2 modular system, they can be quickly and easily adapted to new clamping tasks.

massive and simple

on the mechanical zero point clamping system

GRESSEL gredoc

simple and fast with 4 screws

between 5 – 40 kN with

low clamping torque

OP 10 (grip) und OP 20 (smooth)

with system and top jaws

as modular system

massive and simple

on the mechanical zero point clamping system

GRESSEL gredoc

simple and fast with 4 screws

between 5 – 40 kN with

low clamping torque

OP 10 (grip) und OP 20 (smooth)

with system and top jaws

as modular system

massive and simple

on the mechanical zero point clamping system

GRESSEL gredoc

simple and fast with 4 screws

between 5 – 40 kN with

low clamping torque

OP 10 (grip) und OP 20 (smooth)

with system and top jaws

as modular system

massive and simple

on the mechanical zero point clamping system

GRESSEL gredoc

simple and fast with 4 screws

between 5 – 40 kN with

low clamping torque

OP 10 (grip) und OP 20 (smooth)

with system and top jaws

as modular system

massive and simple

on the mechanical zero point clamping system

GRESSEL gredoc

simple and fast with 4 screws

between 5 – 40 kN with

low clamping torque

OP 10 (grip) und OP 20 (smooth)

with system and top jaws

as modular system

massive and simple

on the mechanical zero point clamping system

GRESSEL gredoc

simple and fast with 4 screws

between 5 – 40 kN with

low clamping torque

OP 10 (grip) und OP 20 (smooth)

with system and top jaws

as modular system

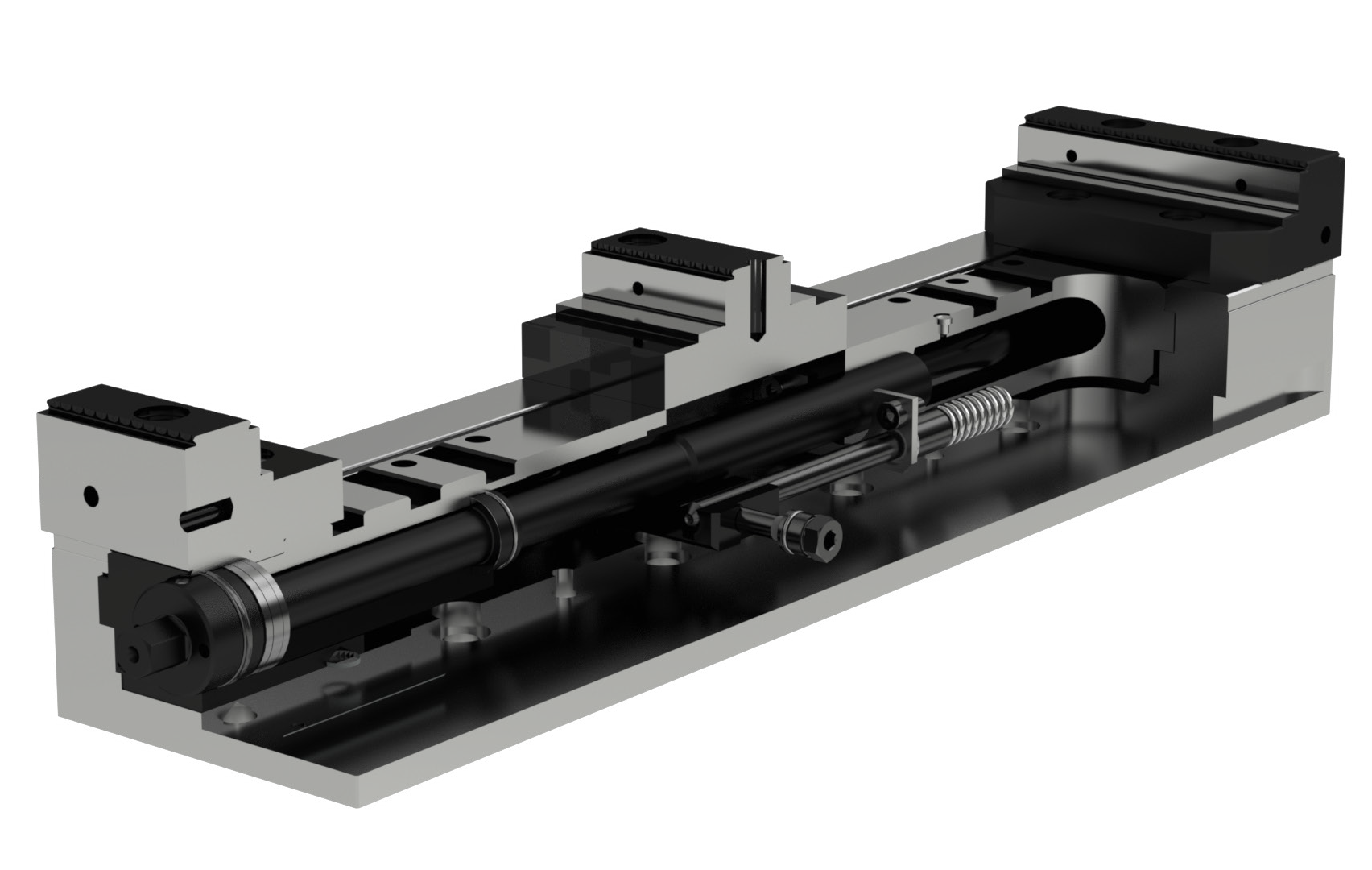

Fixed middle jaw for high precision

Clamping jaws moveable

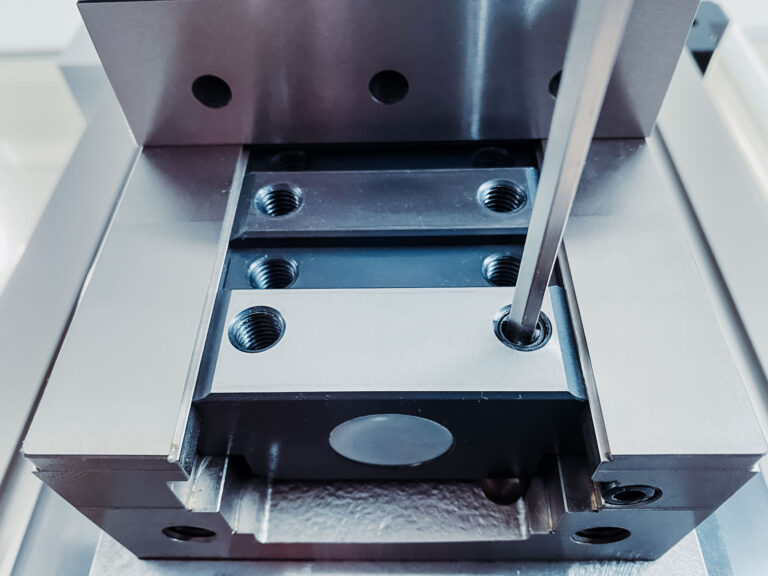

Reliable and safe processes based on encapsulation

Clamping with clamping leveror torque wrench

Precise and long-term accuracy

Low base body

Massive and simple third-hand function

High clamping force with low torque

Advantages that will

inspire you

✓ Perfect for automation – extremely flat design

for maximum utilization of the machine room

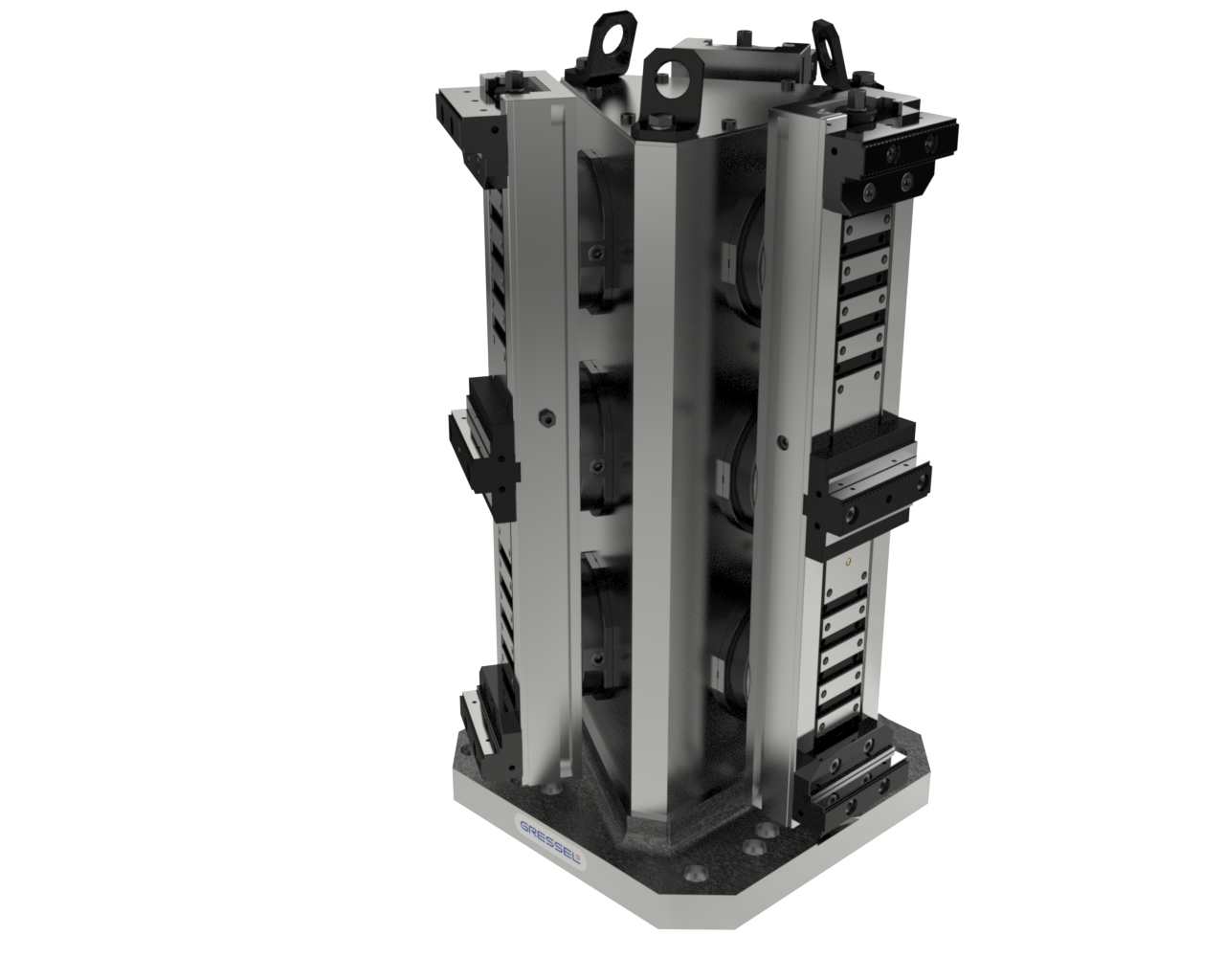

✓ Innovative slide valve encapsulation

perfectly prepared for tower solutions

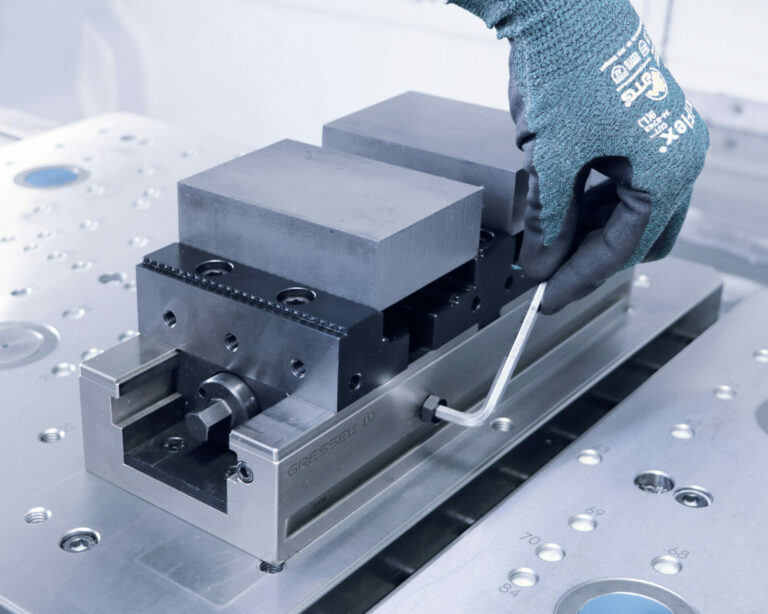

✓ Third hand function & spindle encapsulated

Safe pre-clamping of the first workpiece when clamping the second workpiece

✓ Low-maintenance clamping device

dirt-resistant and low-maintenance clamping device

Our designs

double vise D2

Important data at a glance

| Size | Clamping force | Dimensions (Base Body) | Clamping range max | Weight |

|---|---|---|---|---|

| D2 80 L-300 | 0 – 25 kN | 300 x 80 x 55 mm | 0 – 122 mm | 8 kg |

| D2 125 L-320 | 0 – 40 kN | 320 x 125 x 60 mm | 0 – 114 mm | 14 kg |

| D2 125 L-390 | 0 – 40 kN | 390 x 125 x 60 mm | 0 – 149 mm | 17 kg |

| D2 125 L-460 | 0 – 40 kN | 460 x 125 x 60 mm | 0 – 184 mm | 20 kg |

| D2 125 L-530 | 0 – 40 kN | 530 x 125 x 60 mm | 0 – 219 mm | 24 kg |

| D2 125 L-600 | 0 – 40 kN | 600 x 125 x 60 mm | 0 – 254 mm | 27 kg |

| D2 125 L-670 | 0 – 40 kN | 670 x 125 x 60 mm | 0 – 289 mm | 30 kg |

| D2 125 L-740 | 0 – 40 kN | 740 x 125 x 60 mm | 0 – 324 mm | 34 kg |

- 2 years warranty

- Modular system C2.0 / S2 / D2 for pallet automation

- Proven GRESSEL quality

Three clamping options

The right clamping device

for your tasks

Gressel double vise D2 in action

Double clamping vise D2

Function

Third-hand operation

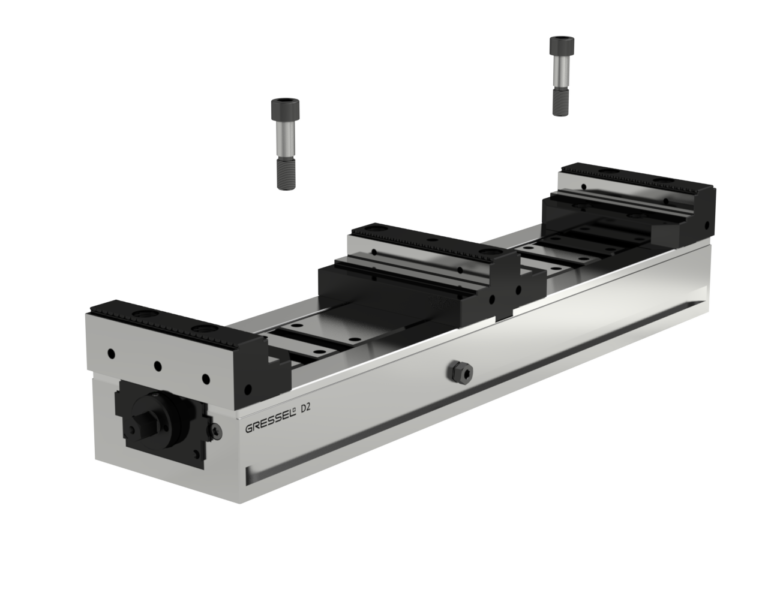

Double clamping vise D2

Conversion

to fixed jaw