Your benefits

The idea of the Gressel clamping technology

construction kit

With pallet automation, the batch size is limited to the number of pallets. However, almost everything can be clamped manually on the pallets, even larger workpieces. With FMS (Fertigung-Manufacturing-Systems) or pallet handling systems, it is similar. Here, however, more pallets are usually available in order to be able to produce more parts. With clamping solutions from GRESSEL formulti-part machining with multiple clamps, pyramids and clamping towers, the machine runtimesper pallet can be significantly increased and thus guarantee a long unmanned machine runtime.

Why did GRESSEL develop a workholding modular system?

Pallet automation requires new clamping devices:

- Pallet dimensions (320 × 320 / 400 × 400 / 500 × 500 mm)

- Pallets max. weights due to robot handling

- Machining height in the machine

- Price for clamping technology (several pallets)

- lower pallet weights due to robot handling

Criteria for selecting the optimum clamping method:

- Workpiece

- Material

- Shape, dimension, weight

- Surface

- Machining process / machine

- Sequence of machining operations

- Accuracies and tolerances

- Tool accessibility

- Piece numbers & batch sizes

Centric vise C2.0

C2.0 125 L-300

on pallet 320 x 320 mm

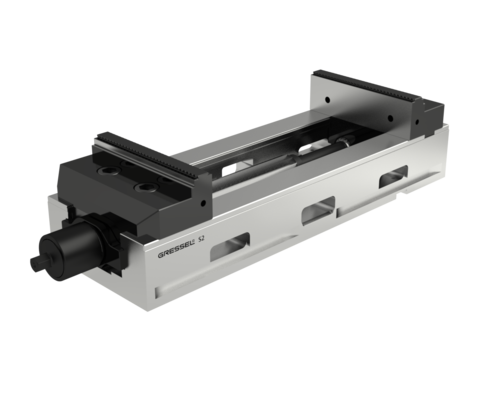

Single vise S2

S2 125 L-362

on pallet 400 x 400 mm

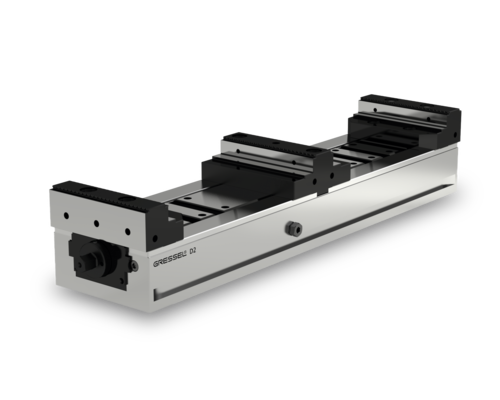

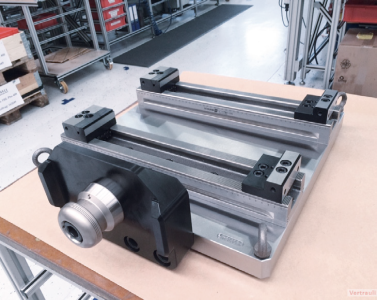

Double clamping vise D2

D2 125 L-460

on pallet 500 x 500 mm

3 Product groups and

over 350 possible combinations

- high clamping forces – no additional work step with pre-stamping necessary

- Simple and practical operation of the clamping devices

- shortest set-up times

- excellent price-performance ratio

Jaw width

80 mm

125 mm

160 mm

Centric vise C2.0

80 mm

125 mm

160 mm

Single vise S2

80 mm

125 mm

160 mm

Double clamping vise D2

80 mm

125 mm

Our Designs

at our customers

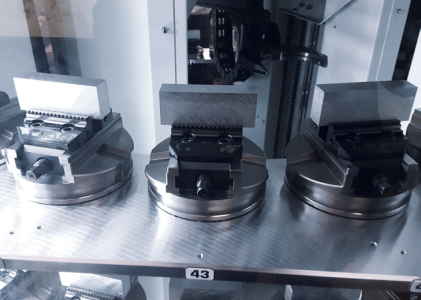

Gressel Pallet automation in action

Our customer CNC-Service Eisemann achieves a significant increase in machine running timeswith the zero-point clamping system!

“The use of GRESSEL zero point clamping systems offer us the highest flexibility, short set-up times, quick changeover of the clamping situation, allocation of production orders within the complete machine park and an increase in productivity due to high machine running times. Overall, the zero-point clamping system offers us a significant increase in machine runtimes and other significant benefits.”

Feedback, Steffen Eisemann, CNC Service Eisemann

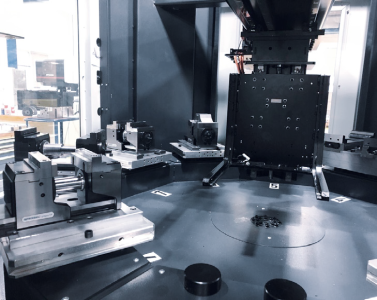

Pallet automation at our customer Schubert Fertigungstechnik GmbH.

When FLEXIBILITY is important! Our zero point clamping system in use at our customer Hohner Maschinenbau GmbH. Quick and easy conversion of the clamping task with the GRESSEL gredoc zero point clamping system. With HERMLE’s pallet automation, the various clamping devices are positioned directly in the machine with the zero-point clamping system and are ready for machining.

Pallet automation in practice at our customer Rhode & Schwarz.

- Increase in machine running time

- Largest workholding program

- Clamping technology modular system C2.0 / S2 / D2

Examples pallet-HANDLING,

the practice

Double clamping vise D2

D2 80 L-300

on EROWA pallet 320 × 320 mm

Centric vise C2.0

C2.0 125 L-160

on gredoc 2-fold pyramid and pallet 630 × 630 mm

5-axis clamping vise SC5X

SC5X L-630

on machines pallet 630 × 630 mm

5-axis force vise grepos-5X

grepos-5X

on pallet 400 × 400 mm

3-fold pyramid C3

C3 L-80

on EROWA pallet 320 × 320 mm

3-fold pyramid C2.0

C2.0 80 L-130

gredoc 3-fold pyramid on a gredoc NRS plate 400 × 400 mm mounted on the machine pallet

Centric vise C2.0

C2.0 80 EROWA ITS 148

calmping vice directly integrated in EROWA pallet

Centric vise C2.0

C2.0 80 L1-90

at HÄBERLE Automation

Centring vise C2.0 & solinos

C2.0 & solinos 65-4V

on pallet 400 x 400 mm

Multiple clamp M1

M1 90 L-400

on SCHUNK pallet 400 x 400 mm

Multi clamping vise multigrip

multigrip

on gredoc angular 3-fold EROWA pallet 630 × 630 mm

individual clamping solutions

grepos-5X

with quick change extensions on a machine pallet 1000 × 1000 mm

Tombstones

Cross tombstone

with C2.0 125 L-160 and forming jaws

individual clamping solutions

Cube tombstone

with S2 125 L-740 and separate fixed jaws