Your benefits

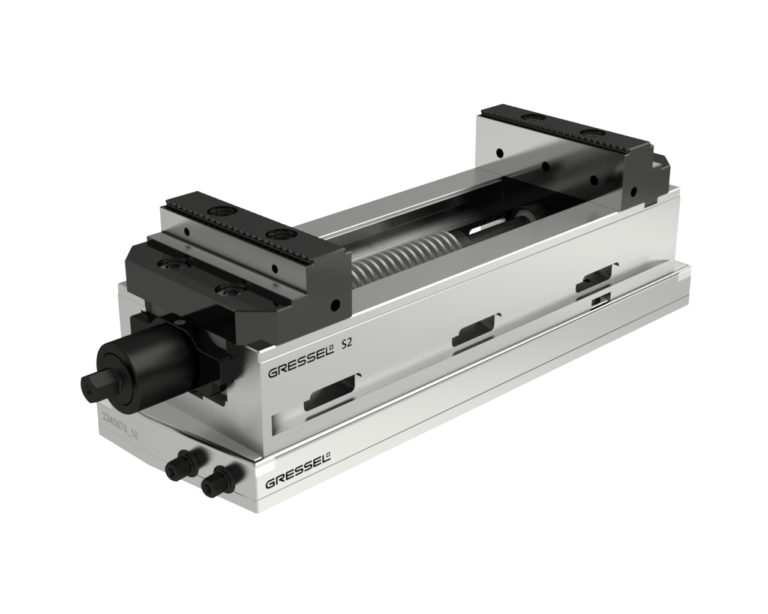

With our single vise S2

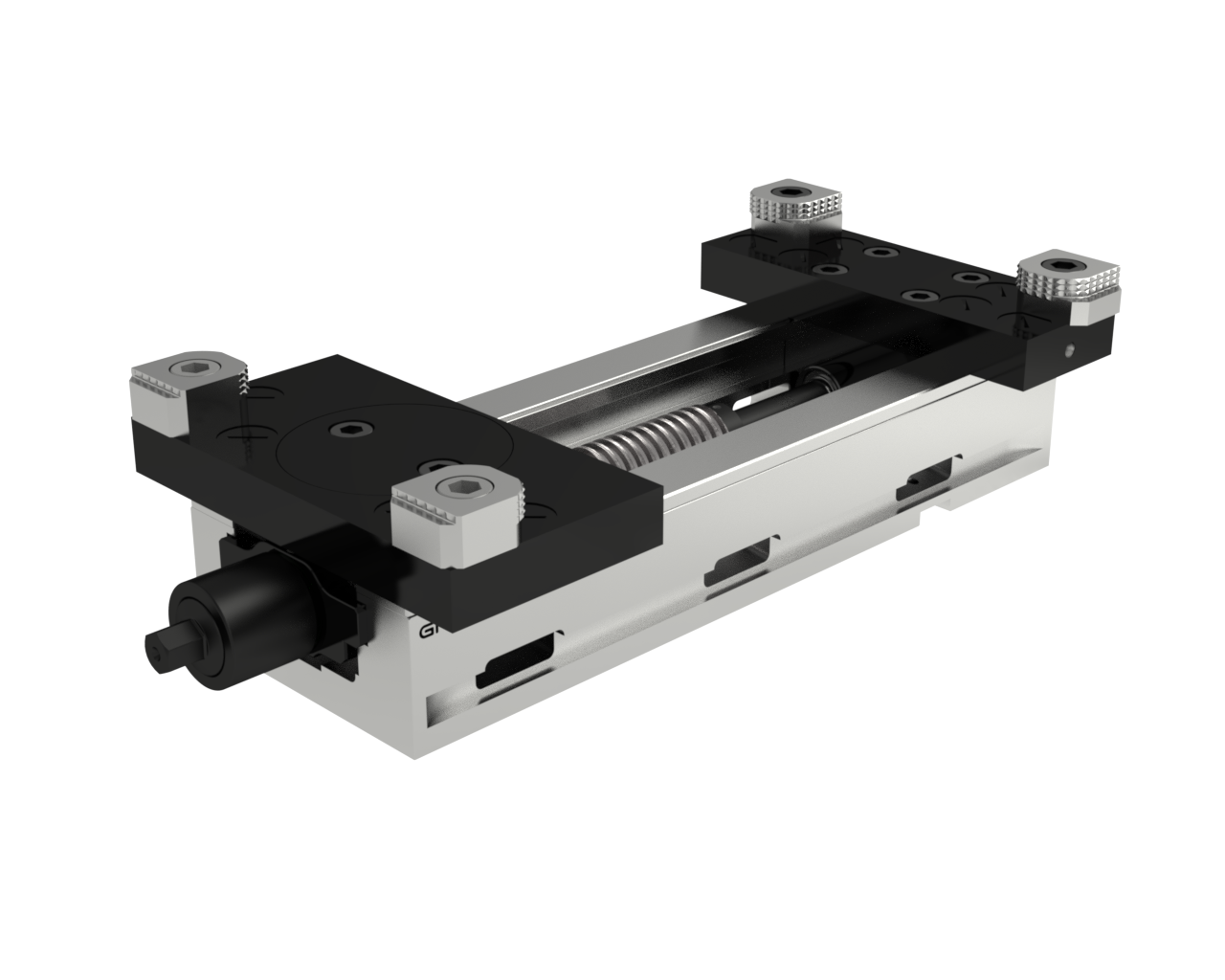

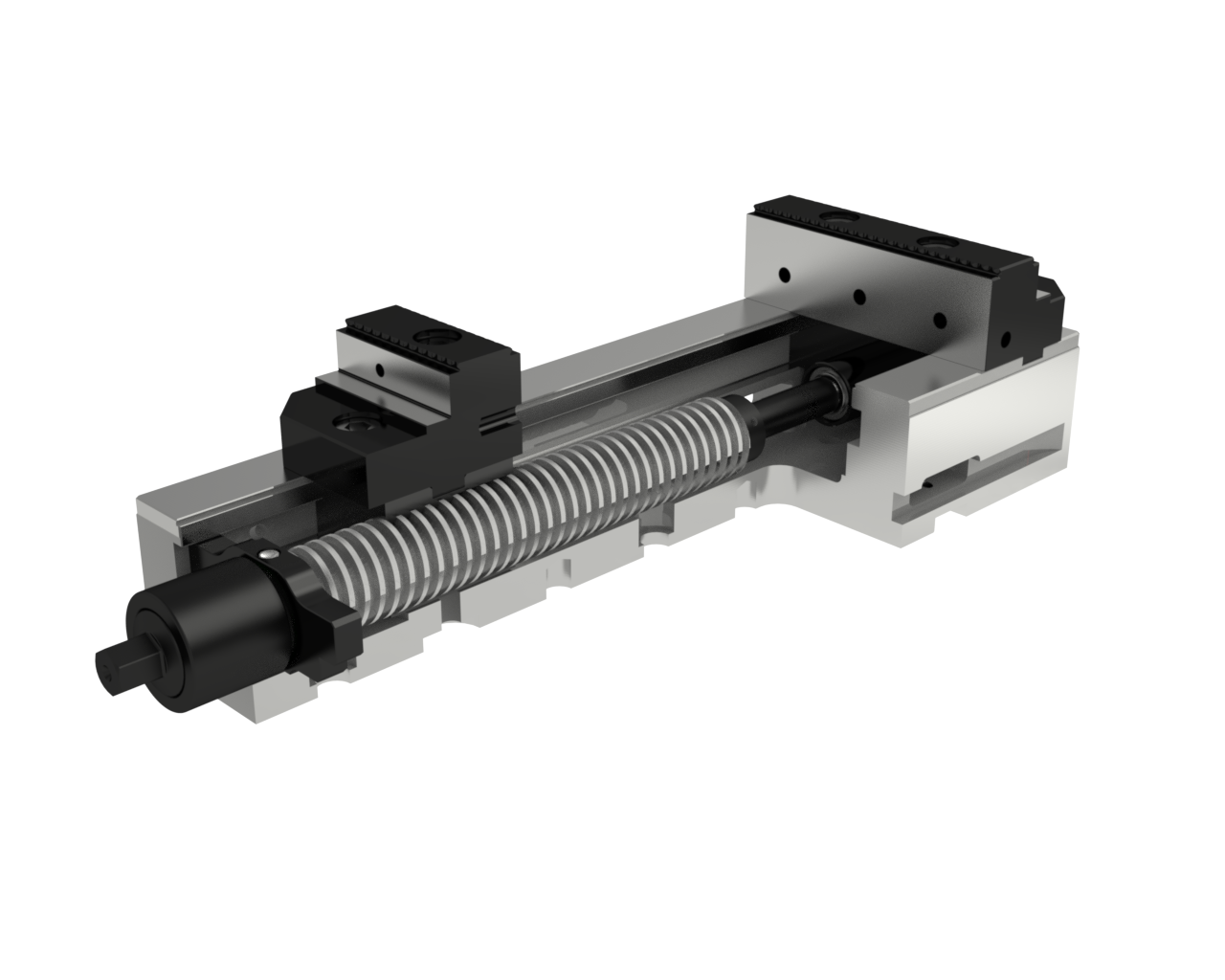

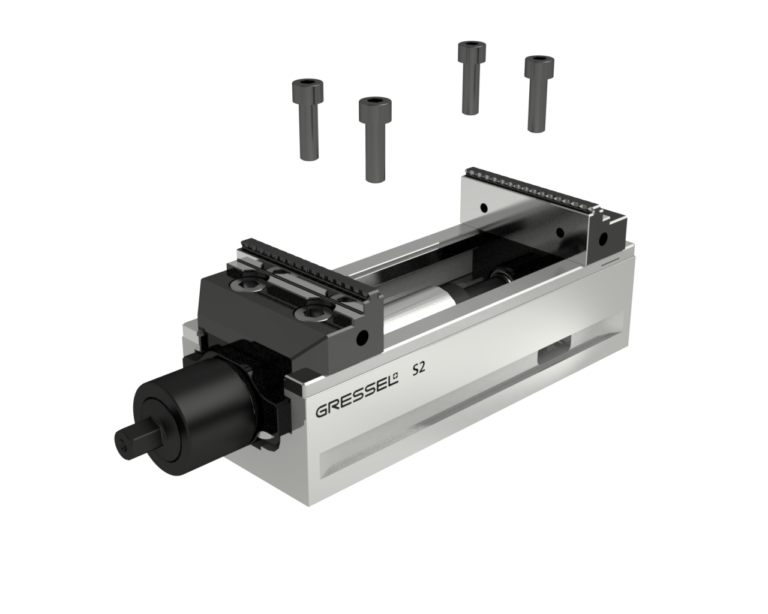

GRESSEL single clamping vise S2 with fixed jaw are especially suitable for use in automatedmachine loading. They score with a quick adjustment of the clamping range, flat design and low weight – perfect prerequisites for use in palletautomation.

multiple coolant drains

on the gredoc zero point

clamping system

between 5 – 50 kN

with low tightening torque

easier and quicker jaw change

with 2 screws

of the spindle unit

jaw program

multiple coolant drains

on the gredoc zero point

clamping system

between 5 – 50 kN

with low tightening torque

easier and quicker jaw change

with 2 screws

of the spindle unit

jaw program

multiple coolant drains

on the gredoc zero point

clamping system

between 5 – 50 kN

with low tightening torque

easier and quicker jaw change

with 2 screws

of the spindle unit

jaw program

multiple coolant drains

on the gredoc zero point

clamping system

between 5 – 50 kN

with low tightening torque

easier and quicker jaw change

with 2 screws

of the spindle unit

jaw program

multiple coolant drains

on the gredoc zero point

clamping system

between 5 – 50 kN

with low tightening torque

easier and quicker jaw change

with 2 screws

of the spindle unit

jaw program

multiple coolant drains

on the gredoc zero point

clamping system

between 5 – 50 kN

with low tightening torque

easier and quicker jaw change

with 2 screws

of the spindle unit

jaw program

High clamping force and largeclamping range

High precision – Repeat accuracy ± 0.01 mm

Lever quick clamping with torque wrench

GRESSEL modular clamping jaws program

precise und wear resistant base body

Easy mounting on machine table or pallet

Advantages that will

inspire you

✓ perfect for automation – extremely flat design

for maximum utilization of the machine room and for optimized total pallet weight

✓ Quick clamping via torque wrench

Simple, fast and safe clamping of the workpiece

✓ Tension on train

No deflection of the base body during clamping, i.e. no intermediate plate necessary for clamping

Extensive jaw program

, optimal adaptation to new clamping tasks with the complete C2.0 / S2 / D2 system jaw program and the GRESSEL top jaws.

Our designs

Single vise S2

Important data at a glance

| Size | Clamping force | Dimensions (Base Body) | Clamping range max | Weight |

|---|---|---|---|---|

| S2 80 L-214 | 0 – 25 kN | 214 x 80 x 55 mm | 0 – 192 mm | 5 kg |

| S2 125 L-362 | 0 – 40 kN | 362 x 125 x 60 mm | 0 – 308 mm | 15 kg |

| S2 125 L-740 | 0 – 40 kN | 740 x 125 x 60 mm | 66 – 682 mm | 30 kg |

| S2 160 L-480 | 0 – 50 kN | 480 x 160 x 70 mm | 0 – 434 mm | 28 kg |

- 2 years warranty

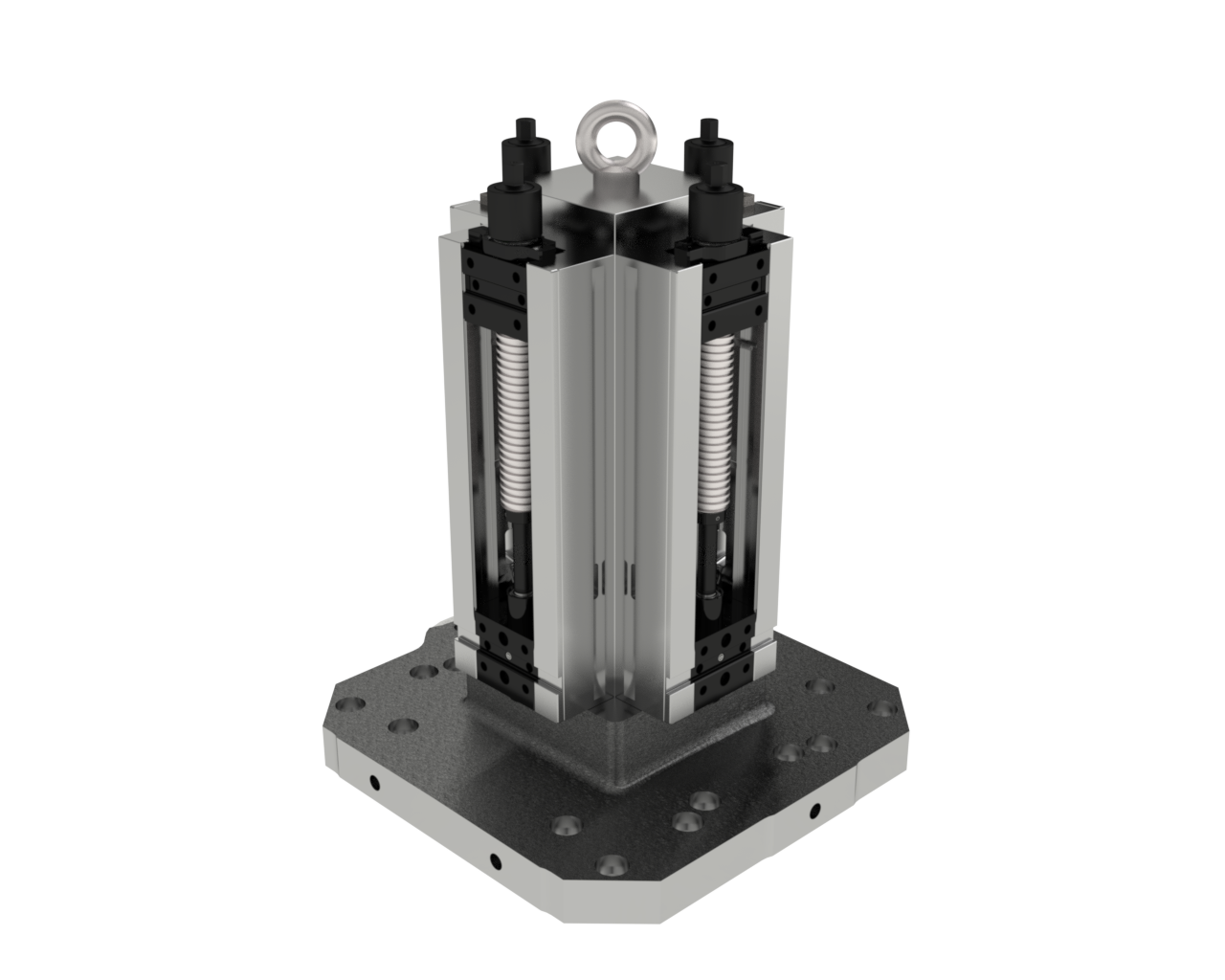

- Modular system C2.0 / S2 / D2 for pallet automation

- Proven GRESSEL quality

Three clamping options

The right clamping device

for your tasks

The S2 offers the following options for mounting on the machine table integrated in the single clamp. Optional: positioning and mounting holes on customer request.

Clamping with fitting screw

all variants can be fixed with screws through the base body

Alignment through precision sliding blocks

all variants can be fastened with clamping claws

Alignment and mounting

with zero point clamping system GRESSEL gredoc

(1-3 mounting bolts)

Optional: positioning and mounting holes on customer request

Gressel single vice S2 in action