Zero point clamping system

Zero point clamping technology for enormous setup time reduction

Zero point clamping technology

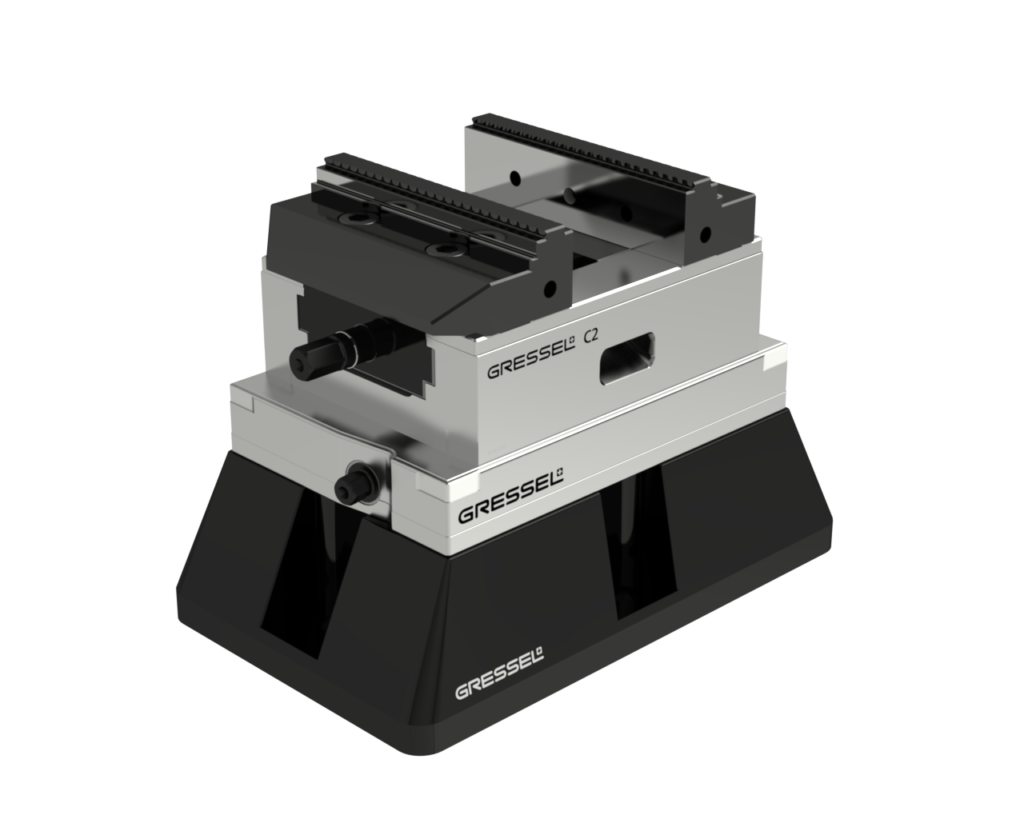

Simple, fast and safe changeover of workpieces or clamping vises on 3-axis, 4-axis or 5-axis machines and fixtures, tombstones or pyramids.The gredoc interface between machine table and clamping vises leads to a significant reduction in set-up time.

Zero point clamping solutions: the most important facts in brief

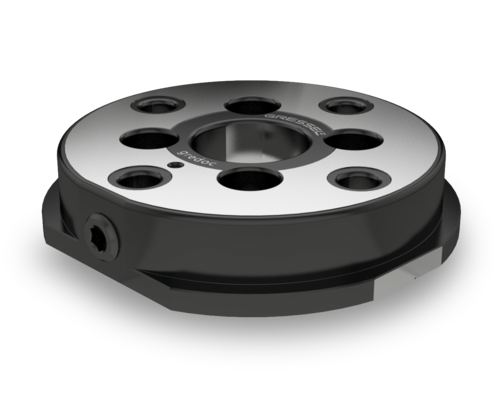

How does the gredoc mechanical zero point clamping system work?

The locating pin is pressed by the clamping bolt into the precisely fitting half shell (polygon). The locating pin is thus positioned accurately in the X / Y direction. At the same time, the locating pin is pulled downwards by the retraction slope with 20 kN.

What are the advantages of a zero point clamping system?

The setup and non-productive times can be extremely reduced, thus increasing the machine spindle running times.

What pull-in force does gredoc achieve?

20 kN pull-in force with 30 Nm torque.

What repeatability is achieved when changing with gredoc?

Highest repeatability <0.01 mm.

How many types of clamping bolts are there?

With the gredoc mechanical zero point clamping system, there is only 1 clamping bolt type and size.

Advantages: Zero point clamping system gredoc

CNC machines, machining centers, pallet changing systems

- Low profile zero point clamping system

- Height only 30 mm ± 0.005

- Low friction and resistant to chips

- Pull-in force 20 kN

- Easy cleaning

Advantages: Zero point clamping system gredoc NRS

4-axis machines, 5-axis machines, pallet automation

- Vacuum hardened stainless steel plates

- Low construction 30 mm

- Mechanical clamping and unlocking

- Pull-in force per module 20 kN

- Hardened fitting buxus with grid 50

- High tilt rigidity

Advantages: Construction kit gredoc

Set up quickly and efficiently

- Consoles as base for 5-axis machines

- Multi-adapter plates

- Gredoc chuck for high precision contour clamping

- 2 years warranty

- Accurate positioning

- Higher machine running time