Your benefits

With our

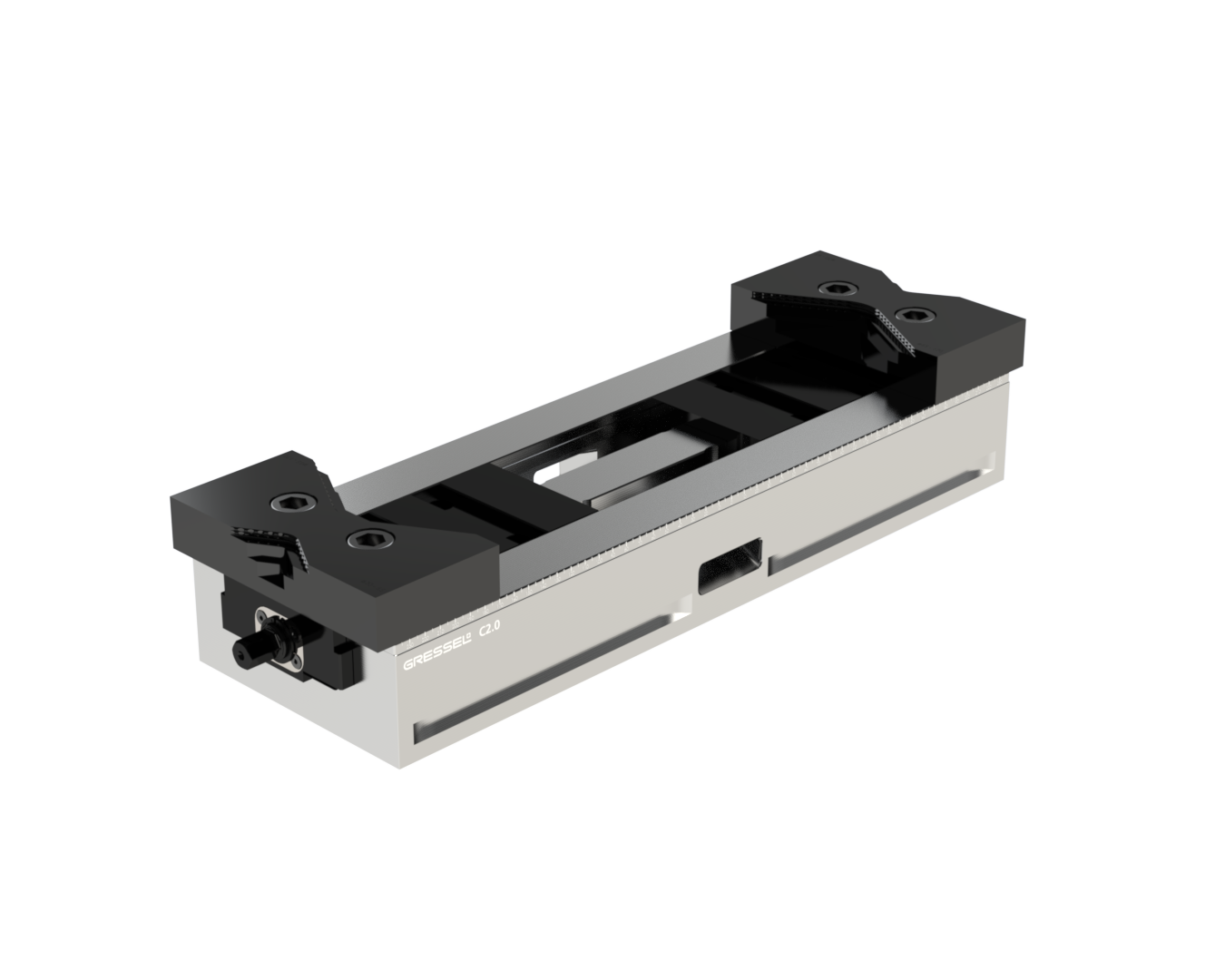

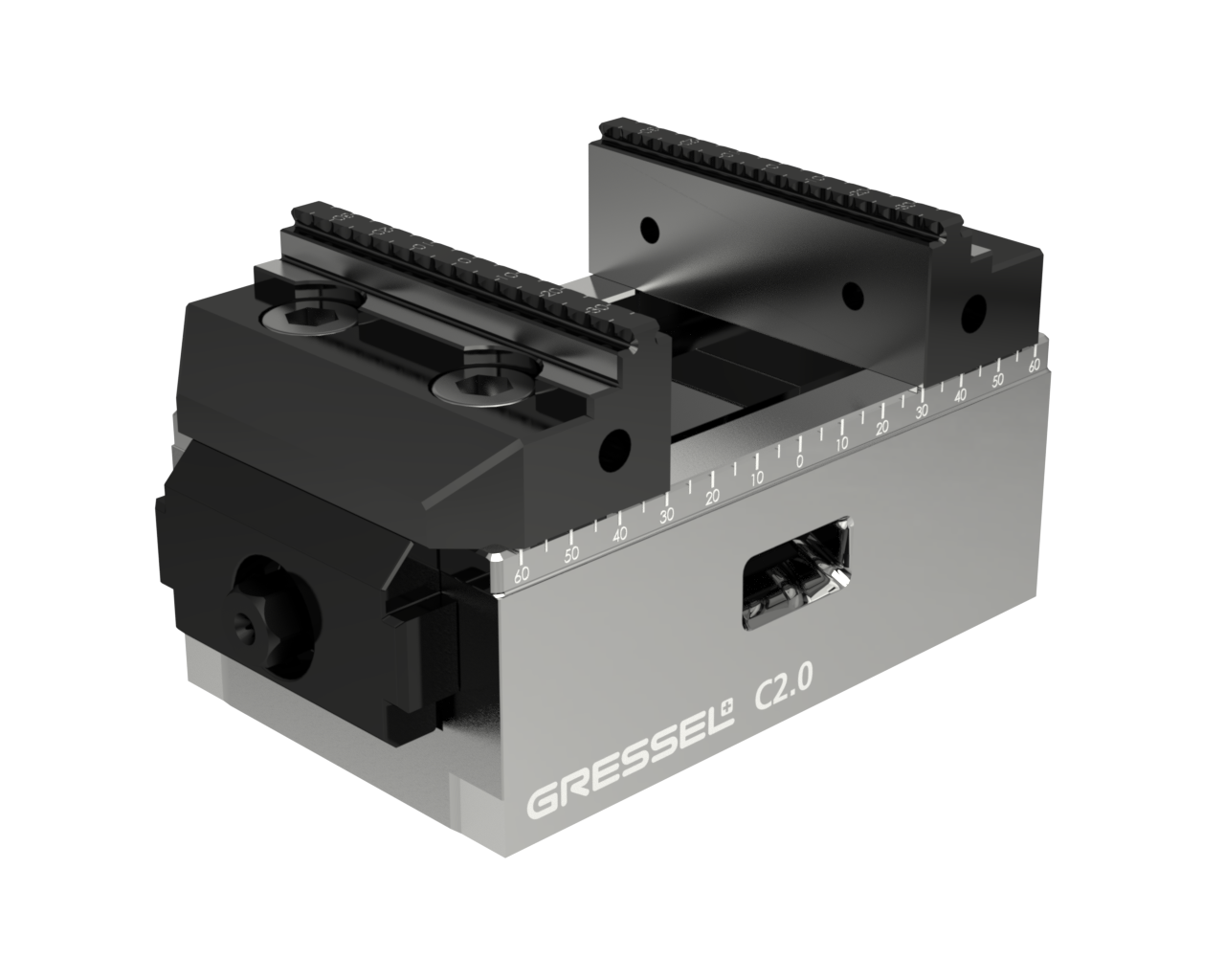

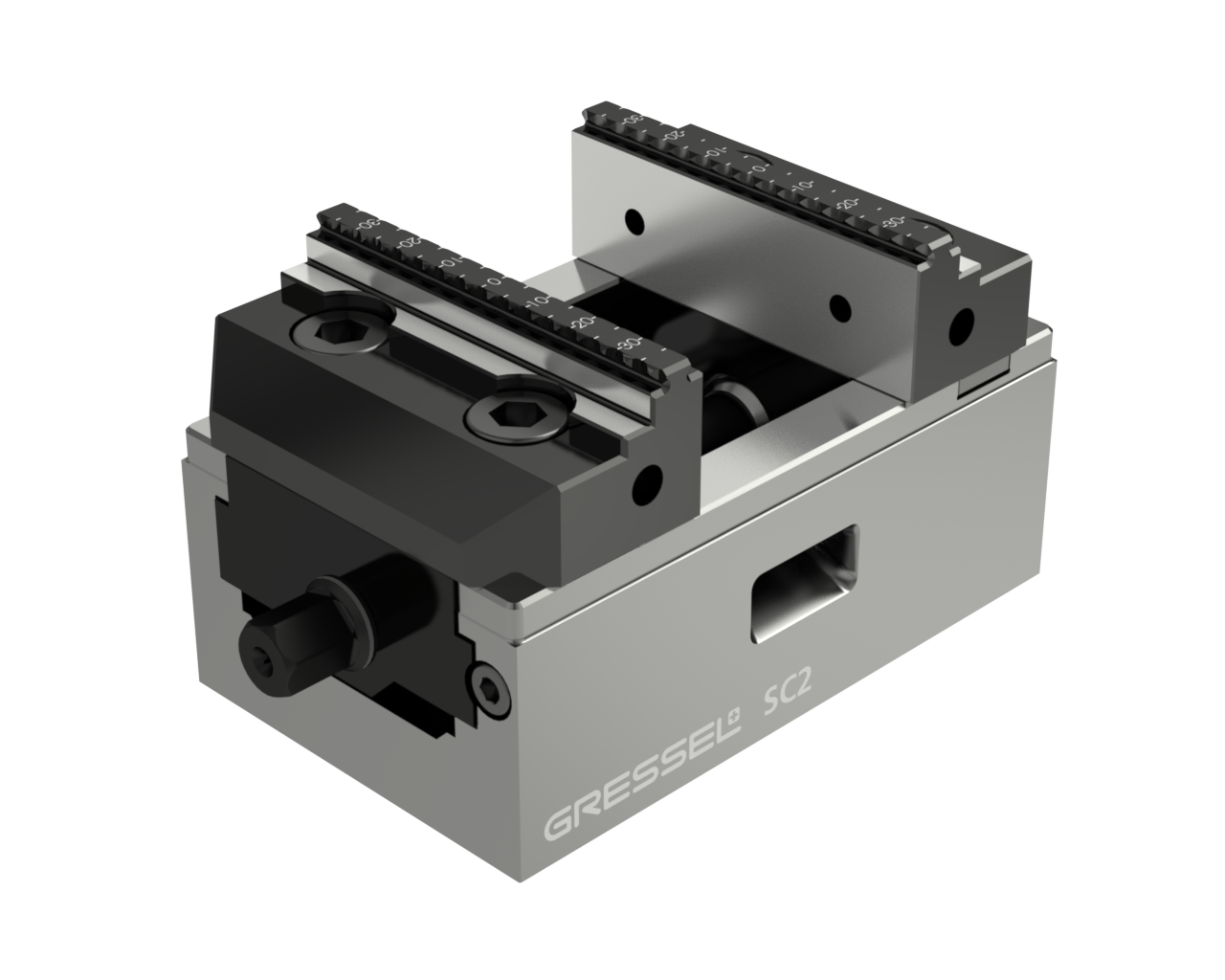

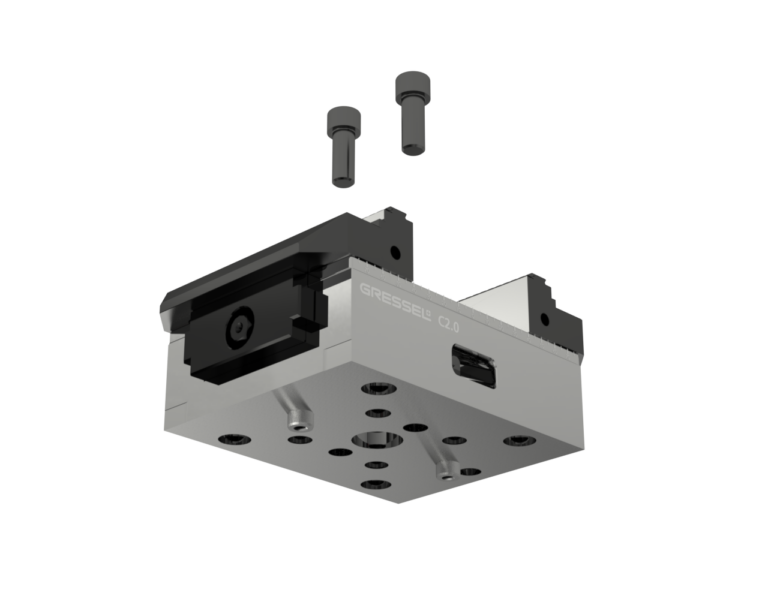

Centric vise C2.0

Whether from centric or up to high-precision clamping systems and in a variety you have not seen before – this is our C2.0 product family. With the C2.0 you will always find exactly the right clamping device for your task thanks to our modular system. GUARANTEED!

closed system, high process reliability

and therefore no pre-stamping necessary

with best accessibility

with system and top jaws as modular system

due to clearance-free bearing

simple and safe with 2 screws

closed system, high process reliability

and therefore no pre-stamping necessary

with best accessibility

with system and top jaws as modular system

due to clearance-free bearing

simple and safe with 2 screws

closed system, high process reliability

and therefore no pre-stamping necessary

with best accessibility

with system and top jaws as modular system

due to clearance-free bearing

simple and safe with 2 screws

closed system, high process reliability

and therefore no pre-stamping necessary

with best accessibility

with system and top jaws as modular system

due to clearance-free bearing

simple and safe with 2 screws

closed system, high process reliability

and therefore no pre-stamping necessary

with best accessibility

with system and top jaws as modular system

due to clearance-free bearing

simple and safe with 2 screws

closed system, high process reliability

and therefore no pre-stamping necessary

with best accessibility

with system and top jaws as modular system

due to clearance-free bearing

simple and safe with 2 screws

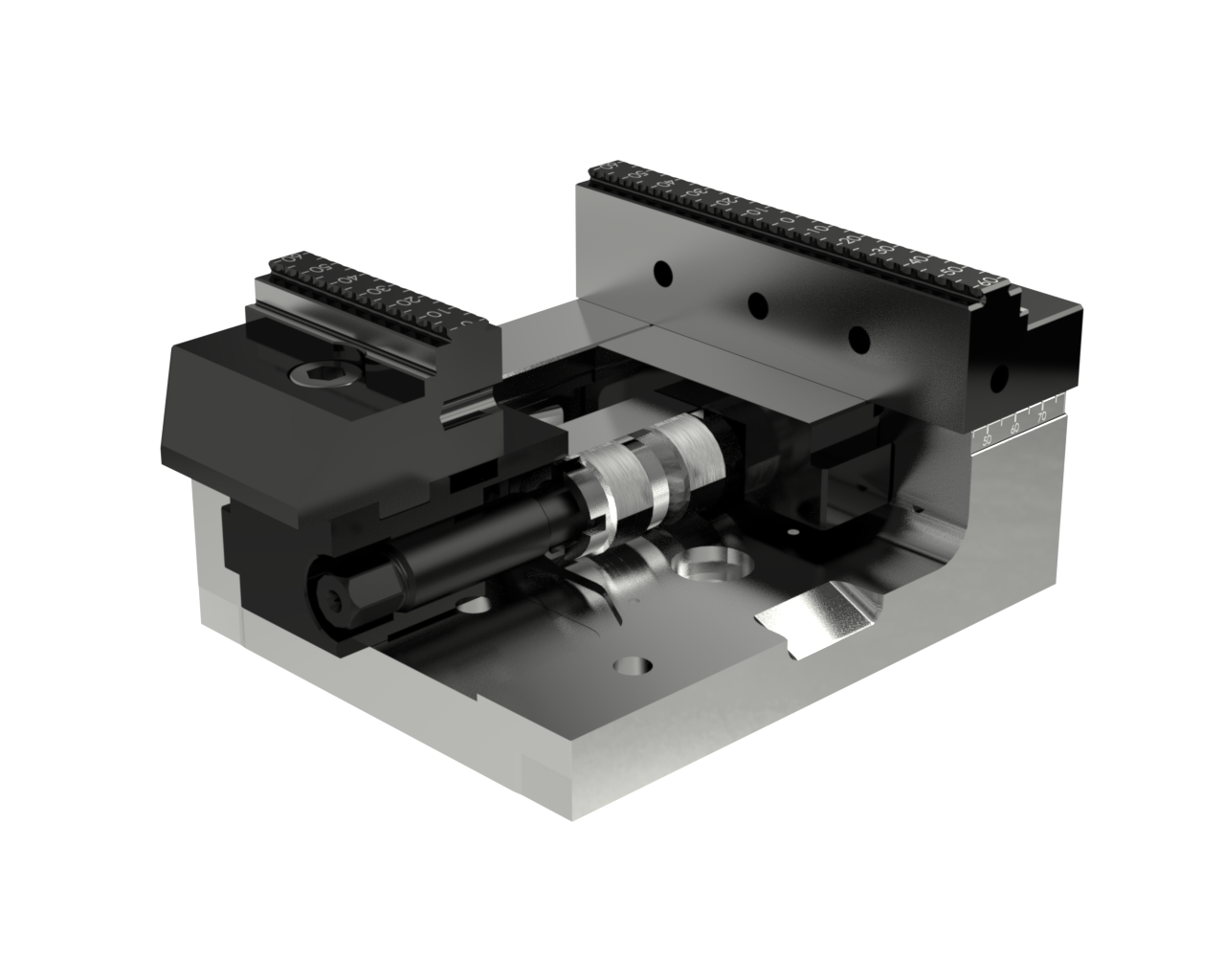

Closed and protected spindle

Compact design

High clamping force and largeclamping range

High accuracy - repeatability ± 0.01 (C2.0 80 + 125) and ± 0.015 (C2.0 160)

Jaw change with only 2 screws - easy jaw interface for own jaws

Ball bearing spindle - Backlash free

1 + 2. side machining possible

Advantages that will

inspire you

✓ Perfect for pallet automation

no one can do it better in pallet automation or on tombstones

✓ Hardly any maintenance

Dirt-resistant and low-interference power transmission

✓ Holds what it has to hold

from plastic to aluminum to hardened materials (up to HRC 58)

✓ Wide range of jaws

Optimum accessibility for the tool from 5 sides

✓ Long service life

the base bodies of the C2.0 are nickel-plated

✓ Scale / scaling

help to position the system jaws and the workpiece

Our designs

Centric vise C2.0

Important data at a glance

| Size | Clamping force | Dimensions (Base Body) | Clamping range max | Weight |

|---|---|---|---|---|

| C2.0 80 L-130 | 0 – 25 kN | 130 x 80 x 50 mm | 0 – 121 mm | 4 kg |

| C2.0 80 L-190 | 0 – 25 kN | 190 x 80 x 50 mm | 0 – 185 mm | 5.5 kg |

| SC2.0 80 L-130 | 0 – 25 kN | 130 x 80 x 50 mm | 0 – 111 mm | 2.9 kg |

| SC2.0 80 L-190 | 0 – 25 kN | 190 x 80 x 50 mm | 0 – 171 mm | 4.4 kg |

| C2.0 125 L-160 | 0 – 35 kN | 160 x 125 x 50 mm | 0 – 163 mm | 8.7 kg |

| SC2.0 125 L-160 | 0 – 35 kN | 160 x 125 x 50 mm | 0 – 141 mm | 6.4 kg |

| C2.0 125 L-235 | 0 – 35 kN | 235 x 125 x 50 mm | 0 – 226 mm | 11.7 kg |

| SC2.0 125 L-235 | 0 – 35 kN | 235 x 125 x 50 mm | 0 – 211 mm | 9.3 kg |

| C2.0 125 L-300 | 0 – 35 kN | 300 x 125 x 50 mm | 0 – 303 mm | 14 kg |

| SC2.0 125 L-300 | 0 – 35 kN | 300 x 125 x 50 mm | 0 – 281 mm | 11.8 kg |

| C2.0 160 L-280 | 0 – 45 kN | 280 x 125 x 70 mm | 0 – 251 mm | 21 kg |

| SC2.0 160 L-280 | 0 – 45 kN | 280 x 125 x 70 mm | 0 – 245 mm | 21 kg |

| C2.0 160 L-480 | 0 – 45 kN | 480 x 125 x 70 mm | 0 – 465 mm | 35 kg |

| SC2.0 160 L-480 | 0 – 45 kN | 480 x 125 x 70 mm | 0 – 448 mm | 35 kg |

| C2.0 125 XL L-390 | 0 – 35 kN | 390 x 125 x 60 mm | 24 - 377 mm | 17 kg |

| C2.0 125 XL L-460 | 0 – 35 kN | 460 x 125 x 60 mm | 24 - 447 mm | 20 kg |

| C2.0 125 XL L-530 | 0 – 35 kN | 530 x 125 x 60 mm | 24 - 517 mm | 24 kg |

| C2.0 125 XL L-600 | 0 – 35 kN | 600 x 125 x 60 mm | 24 - 587 mm | 27 kg |

| C2.0 125 XL L-670 | 0 – 35 kN | 670 x 125 x 60 mm | 24 - 657 mm | 30.5 kg |

| C2.0 125 XL L-740 | 0 – 35 kN | 740 x 125 x 60 mm | 24 - 727 mm | 34 kg |

- 2 years warranty

- Modular system C2.0 / S2 / D2 for pallet automation

- Proven GRESSEL quality

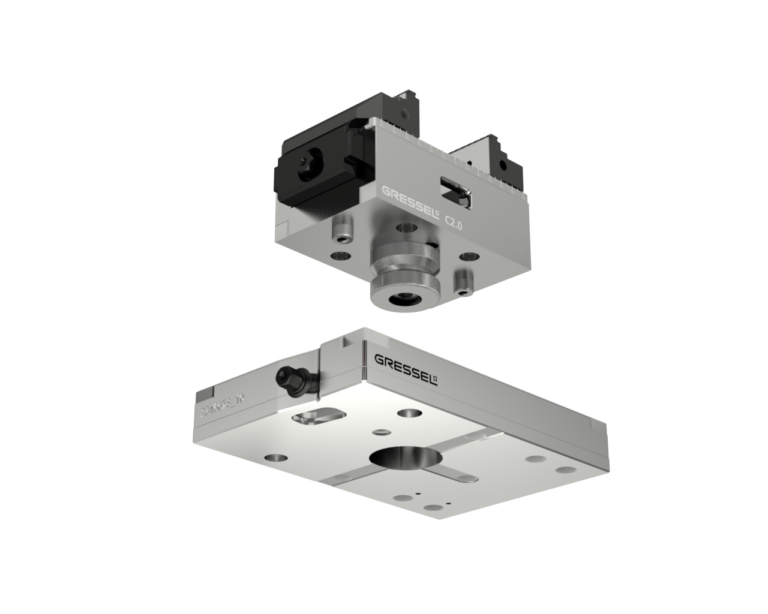

Three clamping options

The right clamping device

for your tasks

The C2.0 offers the following options for mounting on the machine table integrated in the centering vise. Optional: positioning and mounting holes on customer request.

Clamping with 2 fitting screws

All variants with precision bores ᴓ12JS for exact positioning, fastening from above through the base body

Alignment by precision sliding blocks

Longer variants are fastened with clamping claws, some variants with zero point bolt mounting for 52 x 52 and 96 x 96 mm

Alignment and clamping

with zero point clamping system GRESSEL gredoc

(1-3 mounting bolts)

Optional: positioning and mounting holes on customer request

Gressel centric vise c2.0 in action