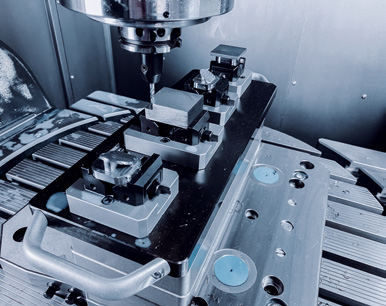

Grissemann Maschinenbau GmbH has searched the entire market and was very satisfied with the price-performance ratio and the flexibility of the clamping devices is also perfect for your needs. Thanks to the automation, the company achieves a capacity utilization of 97% during the day and can set up the workpieces in parallel during peak times.

To the video: https://youtu.be/btZduNbAkqc

Interview with Florian Thaler, Head of the Milling Department at Maschinenbau Grissemann GmbH, Kufstein

You have been with Maschinenbau Grissemann GmbH for 20 years. How have the requirements in the milling shop changed during this time?

Florian Thaler: Yes, the requirements have changed considerably. Technological development has primarily influenced the precision and efficiency of milling processes. When I started, our options were limited. Today, modern technology, such as automation, enables us to achieve high capacity utilization and flexibility.

You mentioned that you have been using GRESSEL vices since the 1980s. What prompted you to come back to GRESSEL?

Florian Thaler: About two years ago, we equipped our milling shop with new automation and searched the market thoroughly for solutions. GRESSEL impressed us with its excellent price-performance ratio and great flexibility. Their vises meet our specific requirements for 5- and 6-sided machining with precision and enable us to design our processes efficiently.

Can you elaborate on the significance of the 5. and 6. side editing and why they are so important for your work?

Florian Thaler: Of course. The 5. and 6. side machining enables us to machine workpieces completely in one clamping operation. This not only significantly reduces the programming effort, but also the processing time per part. With the use of GRESSEL vices and a zero-point clamping system, we can quickly switch between machining the 5. and the 6. change side without having to replace the base body. This saves time and increases our flexibility.

How does automation help you to overcome the challenges of the skills shortage?

Florian Thaler: We are also experiencing a shortage of skilled workers. Thanks to automation, we can carry out many processes in parallel and at the same time, which enables us to achieve a capacity utilization of 97% in some cases during the day. This would not work without automation. Every new machine we purchase is checked for automation potential and equipped accordingly. This helps us to remain efficient and compensate for the shortage of skilled workers.

Finally, how satisfied are you with GRESSEL’s distribution?

Florian Thaler: Very satisfied. The sales force is excellent and the support we receive is first class. It is a strong partnership that helps us to achieve our goals and maximize our productivity.