Why did GRESSEL develop a workholding modular system for pallet automation?

We have the ideal clamping technology for this with our GRESSEL clamping technology modular system – C2 centric clamps, S2 single clamps and D2 double clamps.

Why did GRESSEL develop a workholding modular system for pallet automation?

Pallets Automation requires new clamping devices:

- Pallet dimensions (320 x 320 / 400 x 400 / 500 x 500 mm)

- limited pallets weights because of hadnlings devices

- Machining height in the machine should be as large as possible

- Price for clamping technology because of many pallets

Criteria for selecting the optimum clamping method:

- Workpiece

- Material

- Shape, dimension, weight

- Surface

- Machining process / machine

- Sequence of machining operations

- Accuracies and tolerances

- Tool accessibility

- Piece numbers & batch sizes

Examples of GRESSEL clamping technology kits:

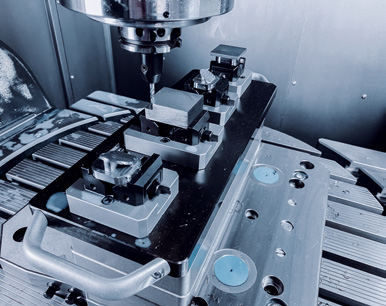

Centring vise C2 125 L-160 on pallet 320 x 320 mm

Double clamp D2 125 L-390 on pallet 400 x 400 mm

Single clamp S2 125 L-362 with pendulum and adapter plate on pallet 500 x 500 mm

Your benefits from the GRESSEL modular clamping system:

Economic efficiency

- Fast setup and easy handling

- Simple conversion to enlarged clamping range

- Products for every budget

Safety

- Shorter machining times due to higher cutting performance thanks to high clamping force

- Longer tool life due to optimum clamping

- safe clamping with GRESSEL grip jaws for every material

Always suitable

- over 300 possible combinations with our construction kit

- The ideal solution for every clamping task without compromise

- Freely combinable components for every requirements

- Can be expanded at any time with products from the modular system

- short delivery time

Best quality

- robust and durable systems

- High precision

- Little wear thanks to well thought-out product concepts

- Minimal maintenance required

- 2 years warranty