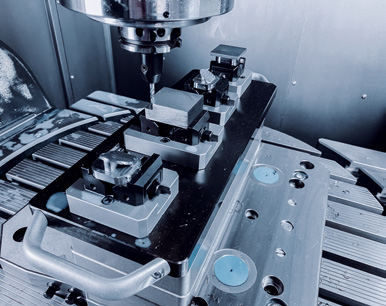

Maximum precision and process reliability

Our single clamping vise SC2.0 in mechanical design with high precision and clamping force. Closed system with optimized chip flow for high process reliability.

The single clamping vise from GRESSEL is also available in other variants:

- Centering vise (with center clamping jaw)

- floating version

The SC2.0 is suitable for OP20 that means for the machining of the 6th side. The continuous cross groove for the fixed jaw increases the accuracy during clamping and holds the position of the workpiece more precisely. With the SC2.0 we have a repeatability of +/- 0.005 with the same tightening torque.

The advantages:

- Closed system

- High clamping force up to 50 kN

- High accuracy

- Jaw change with only 2 screws

- Compact design with best accessibility

- Long service life due to nickel-plated base body

- Scale and scaling: help for positioning the system jaws and the workpiece

Benefit from the high clamping force and large clamping range.

SC2.0 Versions

| Size | Clamping force | Mass (base body) | max. Clamping range | Weight |

| SC2.0 80 L-130 | 0 – 25 kN | 130 x 80 x 50 mm | 0 – 111 mm | 2.9 kg |

| SC2.0 80 L-190 | 0 – 25 kN | 190 x 80 x 50 mm | 0 – 171 mm | 4.4 kg |

| SC2.0 125 L-160 | 0 – 35 kN | 160 x 125 x 50 mm | 0 – 141 mm | 6.4 kg |

| SC2.0 125 L-235 | 0 – 35 kN | 235 x 125 x 50 mm | 0 – 211 mm | 9.3 kg |

| SC2.0 125 L-300 | 0 – 35 kN | 300 x 125 x 50 mm | 0 – 281 mm | 11.8 kg |

| SC2.0 160 L-280 | 0 – 50 kN | 280 x 125 x 70 mm | 0 – 245 mm | 21 kg |

| SC2.0 160 L-480 | 0 – 50 kN | 480 x 125 x 70 mm | 0 – 448 mm | 35 kg |

Clamping possibilities

The SC2.0 can also be designed at the factory with customer-specific positioning and mounting holes as well as receptacles for various zero point clamping systems that accompany the market.

Do you have any questions?

Please feel free to contact us!