The history of the family-run technology company Braun Konstruktionen, 88410 Bad Wurzach/Arnach, could hardly be more typical for a Southern German tinkerer medium-sized company, or the other way around: In 25 years from a design office via its own machine and fixture construction to a sought-after manufacturing technology specialist. In 1990, Anton Braun and his wife Emmi summoned up all their courage and set out to become self-employed, because the creative equipment designer had somehow reached a professional dead end. No sooner said than done, and soon after Braun Konstruktionen was developing and building jigs and special machines, having the mechanical parts manufactured externally and carrying out assembly and commissioning on its own. However, the good business performance soon revealed problems with the suppliers, so Anton and Emmi Braun took heart again and started to invest in their own parts production. Anton Braun has an anecdote about this that speaks for itself: „In order to utilize the capacity of the still young mechanical production facility and justify the investments, which were high by our standards, I started looking for customers myself. To do this, I picked up the daily newspapers and frequently came across job advertisements for the recruitment of CNC specialists. When asked if I wanted to apply, my answer was always, „No, but I want to make their parts!“ Years of development and advancement followed, and the Braun`s made a name for themselves both in the construction of jigs and special machines and in the manufacture of sophisticated parts for the food, dairy and packaging industries, as well as electric motor and general engineering. At the same time, the company realized that it would only be able to hold its own in the long term in the face of fierce competition if it invested in state-of-the-art production technology and high-performance peripherals.

Standardized precision workpiece clamping makes more productive

Consequently, and with the entry of the two sons Harald and Andreas, one responsible for programming, the other for large parts manufacturing, and both for production, the entry into CNC machining was on the agenda in 1995. At the latest, however, it was also clear that in the future all beneficial rationalization possibilities would have to be considered in order to be able to operate the high-quality CNC milling machines and CNC machining centers economically. This includes, among other things, workpiece clamping technology, and here Braun – on the recommendation of its long-time trading partner Nagel Werkzeug-Maschinen GmbH, 89021 Ulm – decided in 1998 to buy precision workpiece clamps from the Swiss specialist Gressel AG, CH-8355 Aadorf. Harald Braun explained: „We have had very good experience with Gressel’s gripos vices and ultimately equipped all relevant machines with them. This saved and still saves us a lot of effort, because the vices can be used very universally and highly flexibly for our order structure, which is normally characterized by individual parts and small batches. In addition, the gripos clamping units are very precise and long-term robust, so that we are well prepared in terms of reproducible accuracy and on the safe side in terms of process reliability.“ Andreas Braun added: „Today, we manufacture workpieces from a few millimeters up to panels in the 1,000 x 3,000 mm format. Simple, fast and reliable workholding handling is very important here in order to keep unproductive downtimes to a minimum. This applies above all to the more highly automated part production, in which we planned to invest from 2013 onwards and then also completed this towards the end of 2014.“

C2 – Precision centering clamp of a different kind

This refers to the procurement of a 5-axis CNC high-performance machining center type C 32 U from Hermle, which is combined with a workpiece magazine and loading system and today represents a self-sufficient flexible manufacturing cell. Initially, the machine was installed in January 2015. This was followed a few months later by the integration of the workpiece magazine and loading system, and this in turn was equipped with the new Gressel type C2 centric clamps. Because almost in parallel with the procurement phase of the BAZ C 32 U, Gressel presented the new C2 centric clamping device at the AMB 2014 trade fair and was able to fully convince its long-standing customer Braun with it on the occasion of another demonstration. Günther Hirschburger, Sales Engineer Germany South at Gressel AG on the advantages of the new C2 family of centric vices: „As a purely mechanical system, the C2 mechanical centric vise is characterized by high accuracy, high clamping force, reproducible clamping precision, complete encapsulation of the spindle drive and adapted design for optimum chip flow. The mechanical accuracy and the preloaded, backlash-free center bearing, in combination with fitted slides, guarantee high repeatability in the range of +/- 0.01 mm for the C2 with 125 mm or +/- 0.015 for the C2 with 160 mm jaw width. Individually adjustable clamping forces of 35 kN (C2-125) or 50 kN (C2-160), and the possibility of first- and second-side machining with one and the same C2 centering vise, bring direct benefits and cost savings to the user, because the otherwise two-stage first-side machining and the associated reclamping/alignment as well as the possible jaw change are no longer necessary. Furthermore, the C2 centering clamps represent an ideal and cost-effective solution for use in workpiece/pallet storage systems, as also practiced by the Braun company.“

Interchangeable jaw grip – embossing and more can be largely eliminated

When the C 32 U BAZ was commissioned, three C2 125 L-160 centering clamps were initially used.

The photo shows the movable workpiece magazine and loading system in front of the 5-axis CNC high-performance machining center C 32 U in the CNC production area at Braun Konstruktionen und Fertigungstechnik in Bad Wurzach/Arnach.

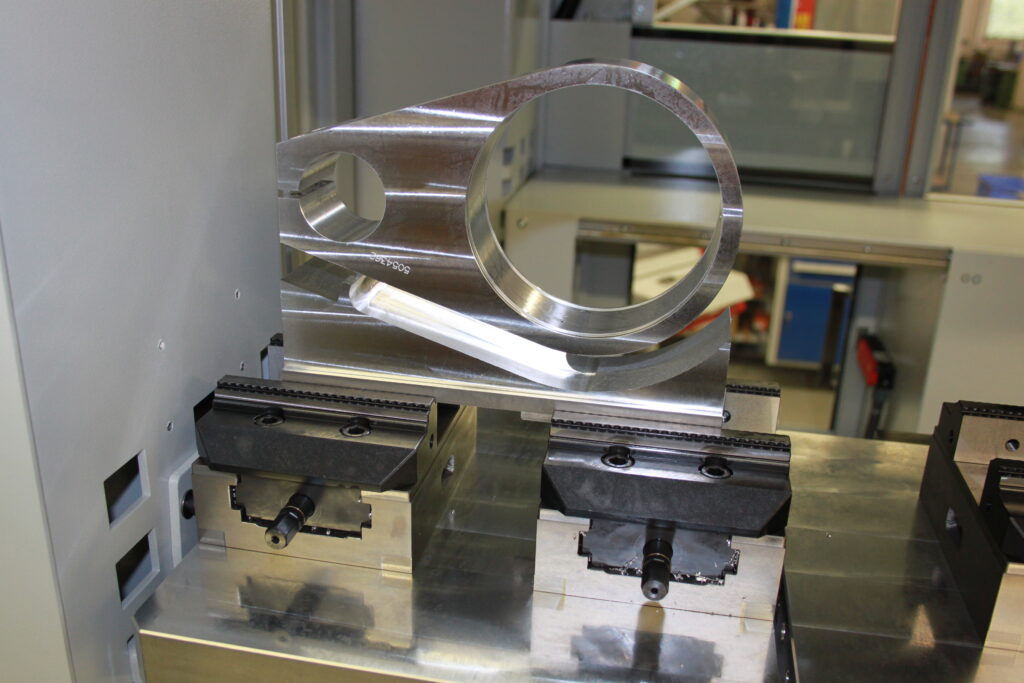

With the workpiece magazine and loading system, another 17 C2 125 L-160 centering clamps were added, so that the production cell currently has 20 clamping units. These are currently mounted on 16 interchangeable pallets, which means that there are sometimes two centering clamps on one pallet, for example when clamping and 5-sided complete machining of longer or large-dimensioned parts is required.

Here you can see the workpiece magazine and loading system equipped with 16 interchangeable pallets and a total of 20 C2 125 L-160 center clamps from Gressel.

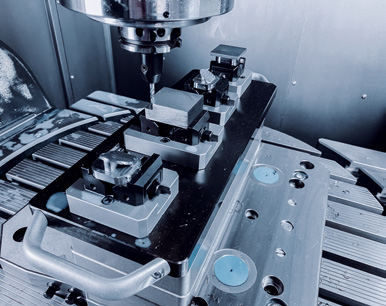

The picture shows the double arrangement of two C2 125 L-160 centering clamps for absolutely centric and thus accurately aligned clamping of a demanding and larger workpiece to be machined in 5 axes.

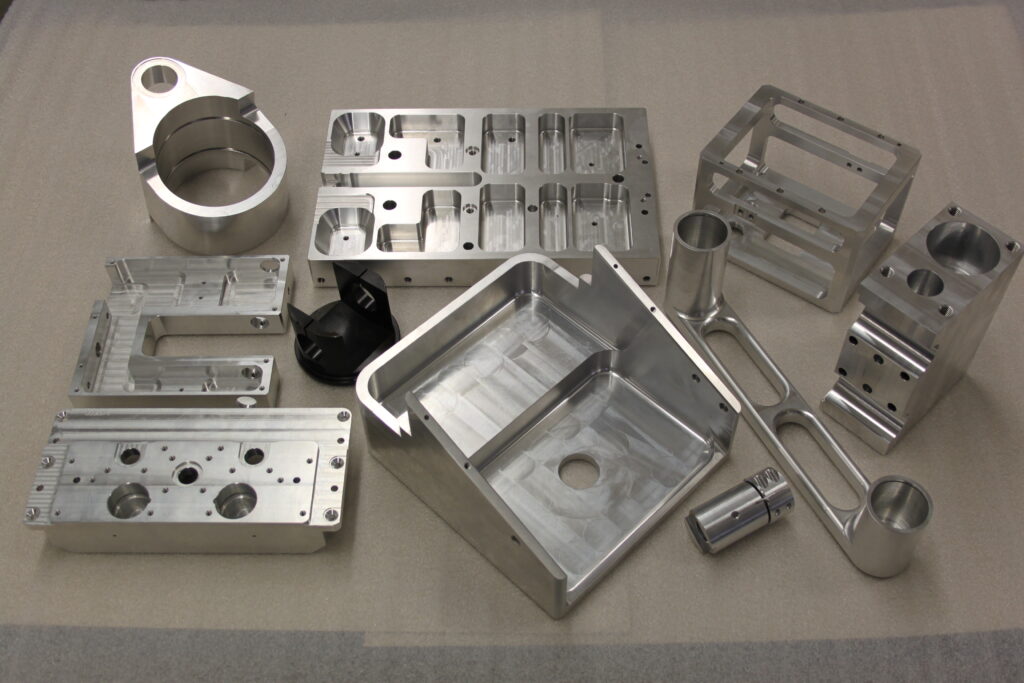

The centering clamps are equipped with grip reversing jaws, thus allowing immediate and form-fit raw part clamping (e.g. saw-rough, non-burred parts), which means that the additional embossing operation can be dispensed with. But there are other advantages that increase or ensure cost-effectiveness, as Harald Braun explained in conclusion: „Automated self-sufficient production also stands and falls with the workpiece clamping technology, among other things. We have equipped all the C2 centering vices in the store with identical clamping jaws in order to be able to perform 5-axis/side/complete/simultaneous machining plus the final machining of the 6th side in just one setup without having to change the jaws. The Gressel centering clamps are mechanically so precise and stable that even with high clamping forces there is no bending up. In addition, the centering accuracy is so high that we also mount the C2 centric clamps on an interchangeable pallet and a high alignment accuracy is given. Other centric clamps cannot do this because they have too much play and bend up too far due to their design. We have tested this and the same applies to the elimination of embossing, which we now only carry out in exceptional cases due to the workpiece.“ In the meantime, the Braun Konstruktionen und Fertigungstechnik company employs 15 skilled workers in 1 to 2 shifts to satisfy its own needs (about 30%) and the needs of its customers (about 70%) for mechanically rather demanding 3- to 5-axis parts to be machined. The workpieces are manufactured from a wide variety of materials such as aluminum, stainless steel, tool steels and plastics and undergo a quality control process that is geared to the well-known high requirements and certifications of the food and medical technology industries.

The photo shows the work area of the 5-axis CNC machining center C 32 U with the NC swivel rotary table and an interchangeable pallet with mounted C 2 125 L-160 centering clamping fixture; the compact and slim design of the centering clamping fixture allows 5-sided complete machining in one setup due to good accessibility from all sides.

From left to right Andreas Braun, responsible for large parts production, Harald Braun, responsible for programming, and both responsible for production at Braun Konstruktionen und Fertigungstechnik, and Günther Hirschburger, Sales Engineer Germany South at Gressel AG.

A small selection of sophisticated workpieces made of a wide variety of materials, as manufactured by Braun Konstruktionen und Fertigungstechnik in all quantities.