The German company DESAGA GmbH is located in Wiesloch. As part of theSARSTEDT Group, DESAGA GmbH is active in the medical industry, more specifically in laboratory automation.

In 2020, the customer purchased a new 5-axis machine type Spinner U630 in order to be able to machine the components and workpieces more efficiently and economically. Mainly workpieces made of aluminum and plastic are machined with a batch size of 1 to 200 pieces. The customer uses the pneumatic zero point clamping system VERO-S from Schunk on the machine table.

Mr. Kirchner, who is responsible for manufacturing, was looking for a mechanical clamping device with very good accessibility so that the company could perform complete 5-axis machining with the shortest possible tools.

Our sales representative, Mr. Klaus Thut and Mr. Joachim Schönenberger (SCHUNK GmbH & Co. KG), were on site at the company DESAGA GmbH. Due to the many years of sales experience and the wide range of clamping products, a clamping solution could be presented which can be optimally used for the customer’s tasks.

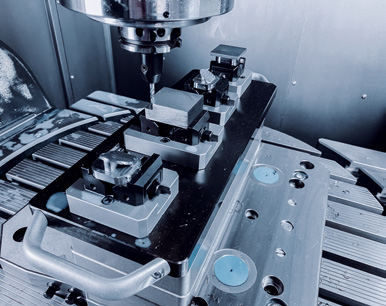

The choice was much on our power-stronger 5-axis clamp, the grepos-5X-C 330, because of the simple and proven handling (clamping force infinitely variable 5-40kN / 160° quick clamping) as well as the mobile fixed jaw can be additionally moved to the center.

Grepos-5X-C in use due to its symmetrical accessibility and high clamping force, optimal and safe 5-sided machining is possible.

Feedback DESAGA GmbH, Mr. Kirchner:

“The clamp from GRESSEL has very good accessibility and is very easy to operate due to its 160° quick clamping.Another plus point is that the mobile fixed jaw can be moved and thus machining in the center is possible.”

From left to right: Mr. Marcel Kirchner DESAGA GmbH, Mr. Klaus Thut Sales Engineer GRESSEL, Mr. Nico Hoffmann DESAGA GmbH, Mr. Joachim Schönberger SCHUNK GmbH.

Your contact:

Klaus Thut,

Sales Engineer

DE Süd / Mitte, NL, BE, LU

klaus.thut[at]gressel.ch

Our sales engineers are also near you!