13 / 12 / 2021

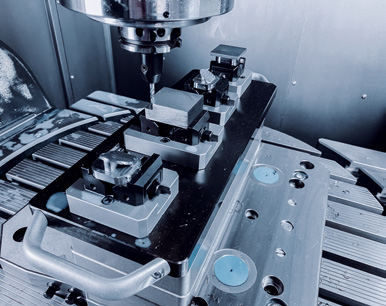

For automation, e.g. for pallet change, pneumatically, hydraulically or electrically operated zero point clamping systems are required. This requires experience and time. With zero point clamping systems, this process is simplified and a lot of time can be saved. Errors are avoided and the spindle running time is increased.

For automation, e.g. for pallet change, pneumatically, hydraulically or electrically operated zero point clamping systems are required.

Mechanical zero point clamping systems such as gredoc are increasingly used for the setup process. These are operated with hand tools and torque wrenches and have many advantages:

- Secure fastening of the clamping devices due to self-locking (similar to screw connection)

- No media supply necessary (no rotary union or hose connection)

- Low overall height of 30 mm for the gredoc, which means that the machine travel distance remains large

- Low platens with zero point clamping systems are lighter, leaving more “payload” for clamping devices and workpieces on the machine