We are your clamping technology partner for automation!

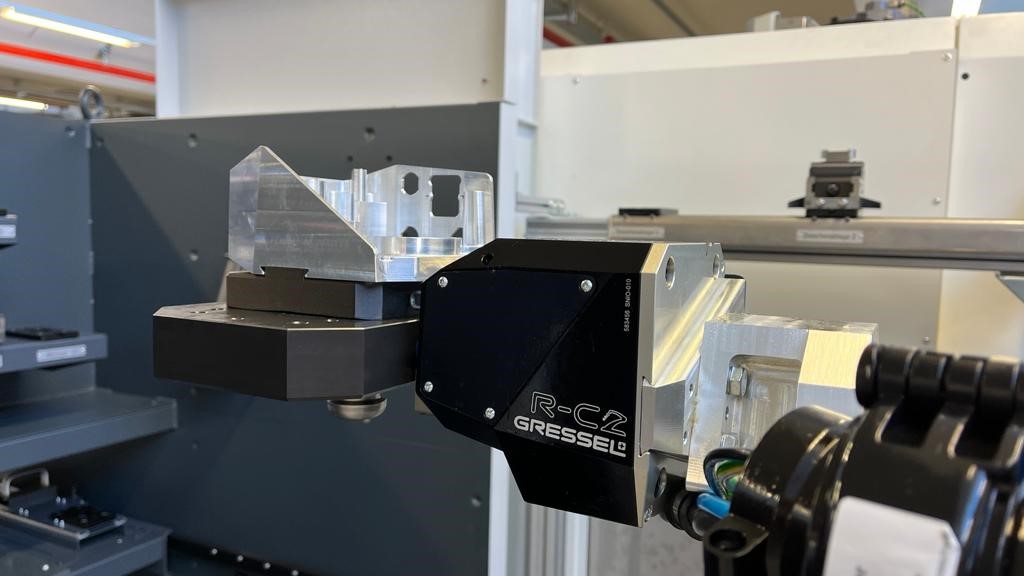

Here you can see the video of the Promro R-C2 system

What are the arguments in favor of R-C2 workpiece automation for a normal contract manufacturer?

You want to be in an automation:

- • not buy 60 clamps or more

- • a mix of clamping technology – clamps with jaw width 80 and 125 mm

- • if possible, also pallets in the system

- • an automation without an extra employee for it (little set-up and changeover times)

- • a flexible automation that can be quickly retooled for a new workpiece.

- a flexible vice

- • different workpieces can be produced completely finished on all 6 sides without any operator.

- • the ability to produce unmanned through the night or on weekends.

- all this together for a manageable investment to start with

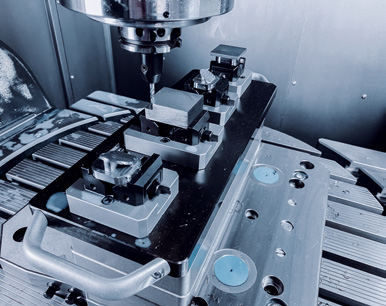

R-C2 Automation – most economical workpiece production:

- • Vise clamping range from 0 – 226 mm ✓ fully automatic

- • programmable clamping force up to 30 kN ✓ fully automatic

- • Vise change (jaw width 80 and 125) ✓ fully automatic

- • Workpiece complete production on all 6 sides ✓ fully automatic

- more machine spindle running times

- lower workpiece manufacturing costs

- no additional employees necessary

- employees can work in day shift, at night or on weekends the R-C2 CNC automation runs automatically

AUTOMATE your processes as a producer, foreman, boss, production manager and machinist with our unmanned 6-sided automation. With a relatively small investment you will achieve more productivity, relieved employees and satisfied customers. More successful production? Success comes AUTOMATICALLY!

Think about tomorrow today:

- Unplanned employee absences

- shortage of skilled workers

- increasing demands on employees

- short-term capacity fluctuations

- cheaper competitors – price pressure is increasing

- decreasing average batch sizes

- customers expect shorter delivery times

With the R-C2 CNC Automation you get:

- the desired flexible vice

- • mixing of clamps is possible (jaw width 80 and 125 mm)

- high adjustable clamping force – no pre-stamping

- • large jaw program & easy own jaw production

- few centric vices in the line

- • very long unmanned spindle running times due to unmanned 6 sides production

- chaotic production with batch size 1 possible

- shortest set-up and changeover times

- no robot knowledge necessary

- combination with pallet handling possible

Have we aroused your interest?

Then please feel free to contact us!