tmv – the name says it all, because behind tmv is the Temel family and their company deals with metal processing and fixture construction. But first things first: In 2000, Ingo Temel, who gave the company its name, ventured into self-employment together with several colleagues after a long period of responsible work in a dental equipment company. When the companions wanted to quit after a few years, Ingo Temel took heart again and was determined to take off. He did this with the awareness of his own strength, the support of his family and the solidarity of his qualified employees. Initially, tmv temel metallverarbeitung & vorrichtungsbau gmbh, A-6833 Klaus, concentrated on parts production as a machining technology service provider for customers from all sectors. Word of the company’s reliable precision turning and milling services quickly spread, prompting one or two customers to inquire whether “more” could be done, for example, in the way that tmv could also deal with subassembly and jig and fixture construction according to specifications. The tinkerer Ingo Temel recognized this as an opportunity, and over time the business area of fixture and special machine construction developed from this. The advantage was and still is to be able to utilize the equipment and skilled personnel required for the machining/manufacturing technology services anyway even better by producing parts for the company’s own needs. Today, tmv presents itself as a typical medium-sized family business in which all family members play a supporting role: As managing director, Ingo Temel is also responsible for the technical management and the design management for the special machine construction, Brigitte Temel is responsible for the commercial part, and the two technology-savvy daughters Patricia and Beate, trained CNC cutting mechanics specializing in milling, are responsible for the CNC production and the mechanical parts production.

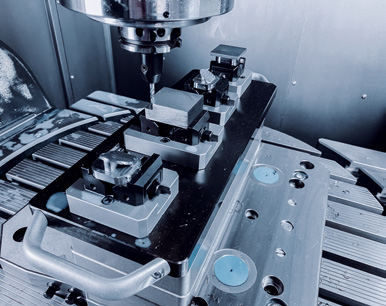

This photo shows the standard workpiece clamping systems from Gressel currently in use at tmv or in the “library”; on the bottom left, the 5-axis force clamp grepos 5X, on the top left, the C2 centering clamp, next to it on the right, the self-configurable collet to fit into the zero-point clamping system gredoc NRS, on the far right, the zero-point clamping system gredoc NRS, and on the bottom right, the extended C2 centering clamp.

Family business in manufacturing practice

tmv now employs 18 people, 15 of whom are involved in CNC manufacturing/production. Ingo Temel on the USP`s of his small but fine technology company: “Our strengths lie in flexibility and high-grade product quality, which result from the competence to implement demanding customer requirements and machining know-how. We can machine turned parts up to the size of 500 mm diameter and 800 mm length and milled parts up to 2,000 mm length. Today, however, the focus is on multi-axis milling of small to medium-sized workpieces, which we manufacture in quantities from 1 and in batches up to several thousand. With the 5-axis/5-side complete/simultaneous machining that we recently invested in, we have been able to expand our customer base and offer more machining options to our existing clientele. However, many of our previously used clamping devices proved to be of limited use, both in terms of clamping solutions for 5-axis machining and workpiece handling in the new CNC machining center, which is equipped with a pallet changer.” Through a very satisfied Swiss customer of many years’ standing, contact was made with the workpiece clamping technology specialist Gressel AG, CH-8355 Aadorf, and further to the presentation of the range of workpiece clamping technology for automated 5-axis CNC machining. After the needs analysis and clarification of the requirements for the universal use of the clamping technology in a very wide range of different workpieces, the decision was made in favor of Gressel clamping technology and various compatible clamping systems were successively procured.

Unerlässlich zur 5-Achsen-Bearbeitung: Passgenaue Werkstück-Spanntechnik!

Patricia Temel, head of CNC production and operator of the new Hermle C 32 UP 5-axis high-performance CNC machining center with pallet changer, comments on the new challenges posed by 5-axis machining: “It quickly became clear to us that we would only be able to make maximum use of the high-end milling performance of the 5-axis machining center if we had adequate, i.e. suitable, workpiece clamping systems. Furthermore, the workpiece clamping technology had to be fast and flexible to handle and set up in order to keep the downtimes of the machining center as short as possible and to be able to carry out the set-up in parallel with the machining time. With the workpiece clamping technology program from Gressel, we liked the systematic, well thought-out design, the stable and precise mechanical design, the high application and usage flexibility, the simple and fast jaw change, or also the encapsulated spindle on the 5-axis vice, as well as the simple and robust, because purely mechanical zero-point clamping system.” At tmv there are currently a universal machine vice gripos, various 5-axis force clamp grepos5X, several zero point clamping systems gredoc NRS, several centering clamps C2, div. gredoc collets for self-configuration and several gredoc pyramids for multiple clamping and for self-configuration in use. The interchangeable pallets with the gredoc NRS zero point clamping systems, including the superstructures such as pyramids or collets as well as special clamping devices, are calculated and adapted to the interference circle contours so that maximum utilization on the one hand and high process reliability on the other hand are guaranteed. At tmv, a kind of “Gressel library” has been created so that the currently required basic clamping systems or change jaws can be accessed immediately and without delay.

Here you can see the gredoc NRS zero point clamping system mounted on an interchangeable pallet and equipped with a triple special clamp adapted to machining requirements; by using the gredoc NRS zero point clamping system, the entire clamping unit can be quickly changed and precisely set up again at any time in a reproducible manner.

An individual multiple clamping solution for 5-axis machining of complex workpieces; the clamping unit consists of the gredoc NRS zero point clamping system, a gredoc pyramid for self-configuration and three C2 centric clamps.

Summary

In conclusion, Ingo Temel said: “With 5-axis milling, the appetite is growing for us as well as for the customers, because we are now more than ever tackling everything that has to do with milling. We work in two shifts, and with the automatic pallet change on the new 5-axis machining center, we are also self-sufficient for a certain period of time, depending on the running time of the individual workpieces or multiple clamped parts. The flexibility of the standardized workpiece clamping technology from Gressel in terms of set-up, retooling, application and use is a great advantage for us. We even go so far as to retrofit standard components, such as the basic pyramid for multiple clamping that can be fixed with the gredoc NRS zero-point clamping system, in order to be able to use the 5-axis technology in an even more targeted manner and to process the workpieces even more efficiently. This is not possible with conventional clamping devices and special clamping devices are far too costly, whereas the Gressel clamping technology program leaves all possibilities open to us here and further opens up completely new ones.”

From right to left Brigitte Temel, Commercial Manager, Ingo Temel, Managing Director, Patricia Temel, CNC Production Manager of tmv temel metallverarbeitung & vorrichtungsbau gmbh.

A small selection of precision workpieces as they are manufactured at tmv in all quantities and from all machinable materials.